Machining method of high-precision special-shaped curved surface

A special-shaped curved surface and processing method technology, applied in the direction of measuring devices, instruments, etc., to achieve the effect of high processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

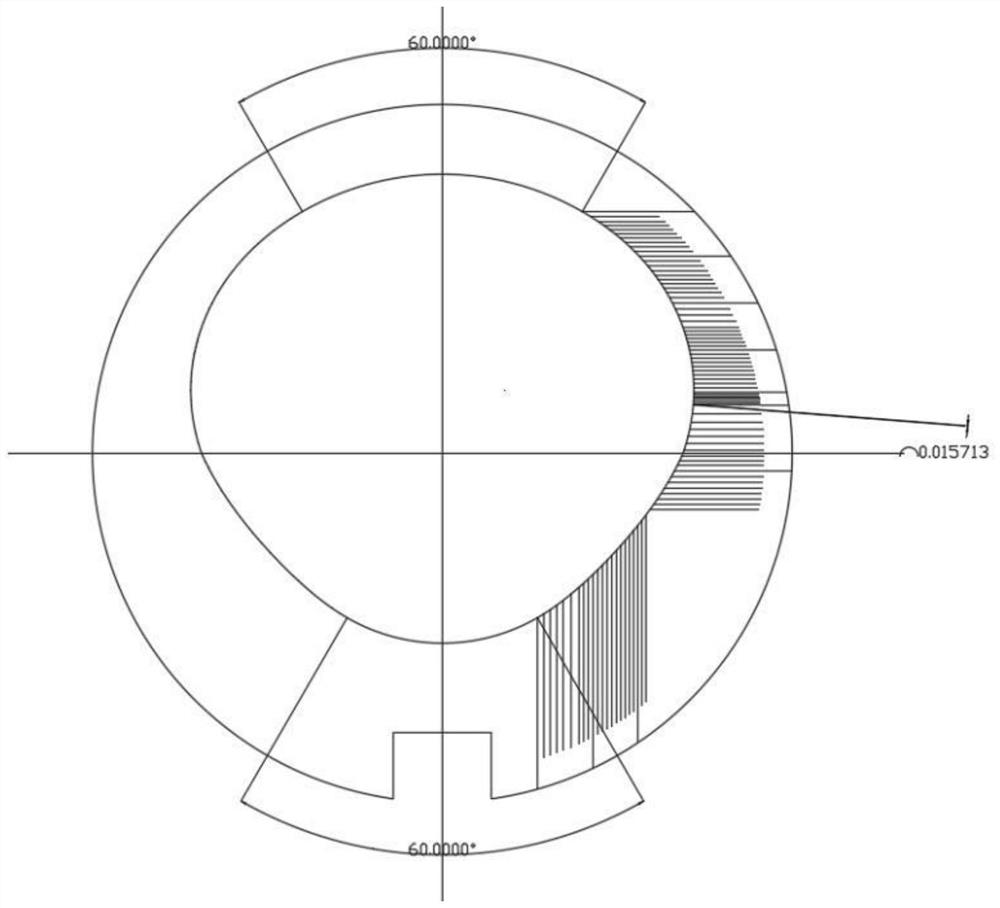

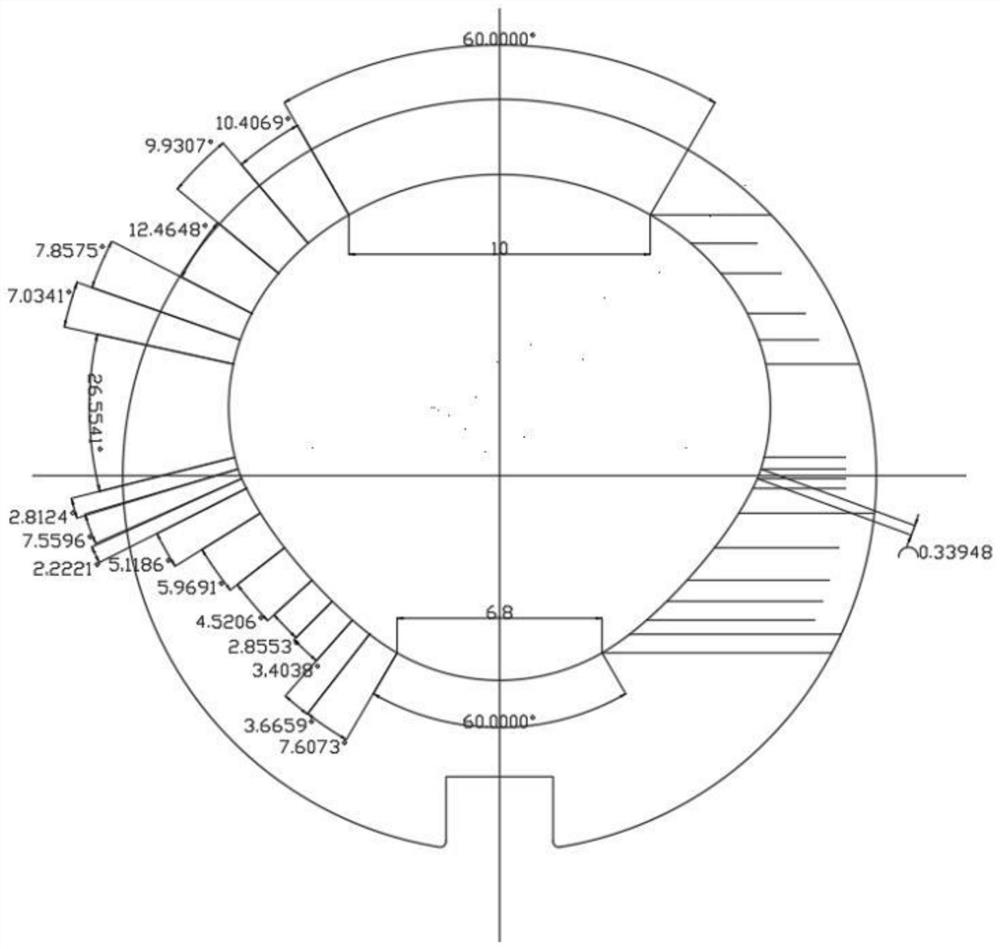

[0056] This embodiment mainly takes the fitting of the inner hole curve of the WHLG10-102 stator as an example in detail:

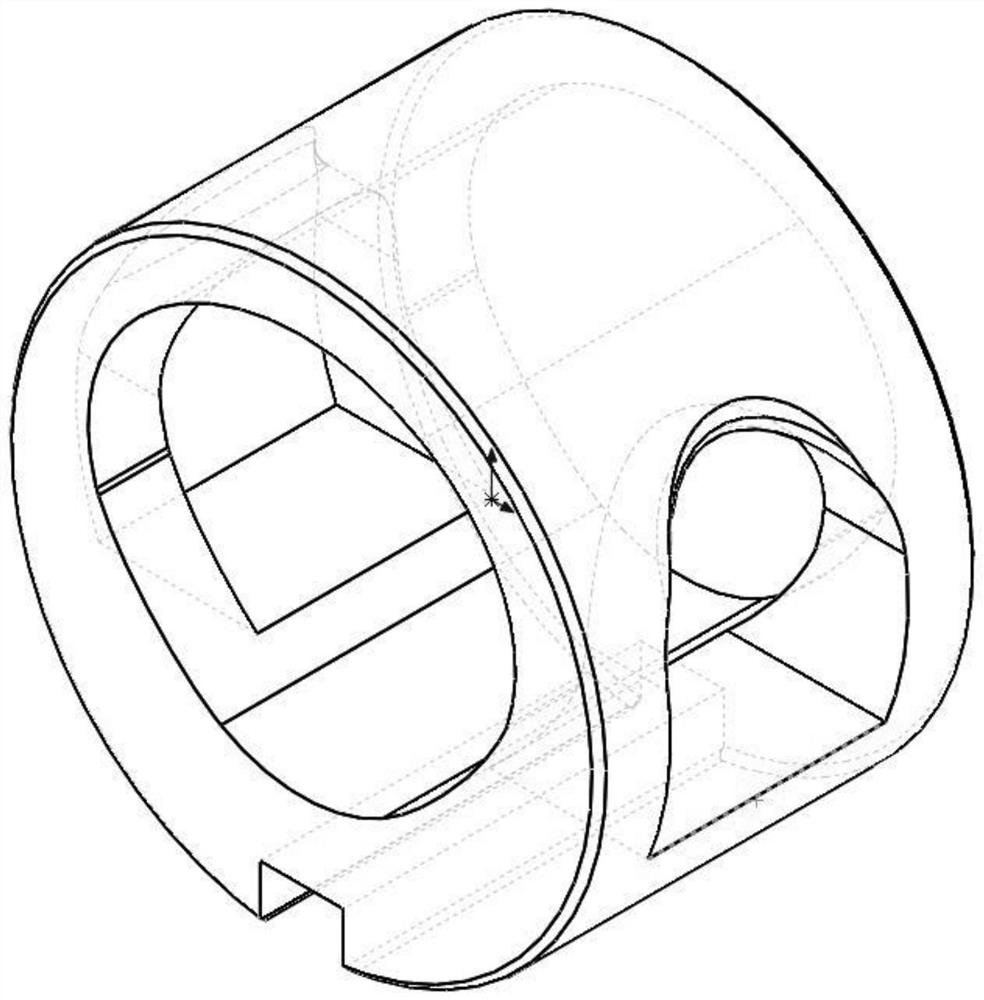

[0057] The above parts such as image 3 with Figure 5 As shown, the material used is YK10S cemented carbide, and the raw material specification is 107*107*18.

[0058] The steps of fitting the internal control curve of WHLG10-102 stator are as follows:

[0059] S1. Generate polylines according to the surface parameters of the workpiece, and decompose the polylines into multiple polylines; wherein, the polylines are composed of multiple straight line segments and / or arc segments;

[0060] Among them, the polyline is formed by function generation or coordinate point fitting; since the polyline cannot be directly recognized by the processing equipment, it is necessary to fit the polyline.

[0061] S2. Identify the straight line segment and / or arc segment in the polyline and mark the starting point, and mark the horizontal or vertical line segment with th...

Embodiment 2

[0094] This embodiment mainly processes the inner rotor of WHLG102-111\112\178, the parts such as Image 6 with Figure 7 As shown, the principle of fitting the surface curve of the part is the same as that of the first embodiment, and will not be repeated here.

[0095] In addition, the processing process of WHLG10-102 stator parts is also explained, and the specific processing steps are as follows:

[0096] B1. Material preparation process: A52183 steel is selected for material supply, and the tailings after production can be recycled;

[0097] B2. Lathe process: outer circle and inner hole D50*60*D10, internal and external chamfering C0.5, tolerance ±0.1;

[0098] B3, heat treatment process: quenching and tempering by heat treatment;

[0099] B4. Grinding machine process: rough grinding the outer circle to see the light;

[0100] B5. Slow wire process: cut the outer tooth profile curve and inner hole, reserve for finishing, and the grinding allowance is 0.2-0.3 per side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com