Automatic quantitative packaging device and packaging method thereof

An automatic packaging and automatic technology, which is applied in the direction of packaging, transportation and packaging, and the type of packaged items, can solve the problems of poor versatility of control components, packaging accuracy and packaging speed of viscous materials that cannot meet production needs, and unstable production. Ensure packaging accuracy, ensure long-term stable operation, and reduce maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

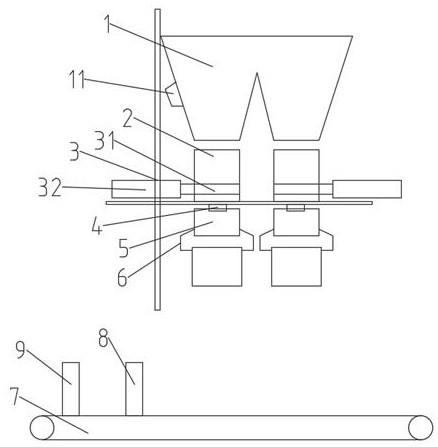

[0044] Such as Figure 1 to Figure 3 Shown, a quantitative automatic packaging device, comprising:

[0045] Frame, material bin 1, unloading device, the material bin 1 is arranged on the frame, and the unloading device is arranged under the material bin 1;

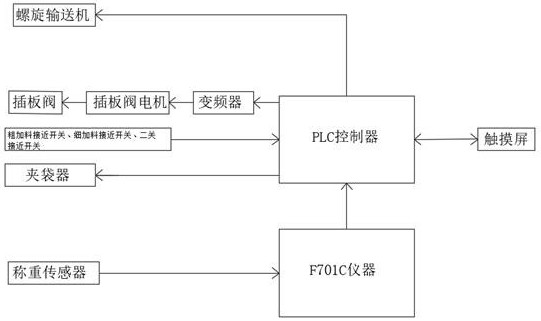

[0046] The feeding device includes a screw conveyor 2, an electric gate valve, a rough feed proximity switch, a fine feed proximity switch, and a two-off proximity switch;

[0047] The feed port of the screw conveyor is connected with the discharge port of the material bin;

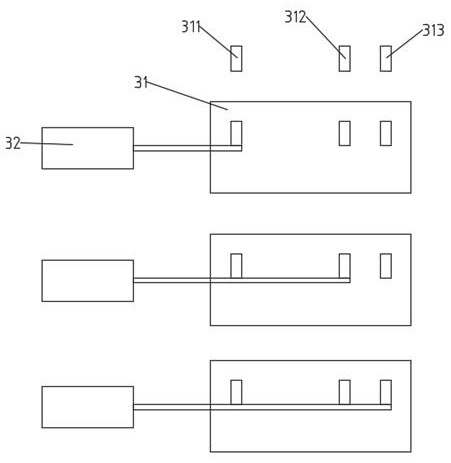

[0048]The electric gate valve includes a gate valve and a gate valve motor, the gate valve is arranged at the discharge port of the screw conveyor, and the gate valve motor is electrically connected with the gate valve for controlling There are three opening and closing states of the gate valve: coarse feed, fine feed, and second close; the rough feed proximity switch, fine feed proximity switch, and second close proximity switch are arranged on th...

Embodiment 2

[0072] This embodiment, as a preferred technical solution of Embodiment 1, also includes: a vibration motor 11, the vibration motor 11 is arranged on the side wall of the material bin 1, the vibration motor 11 is electrically connected with the PLC controller, and the vibration motor 11 is electrically connected to the PLC controller. 11 openings can prevent the overweight of the packaging bag due to the agglomeration of the material in the material bin 1.

Embodiment 3

[0074] This embodiment, as a preferred technical solution of Embodiment 1, also includes: an automatic counter 9, the automatic counter 9 is arranged at the end of the belt conveyor 7, and unqualified products may appear during the packaging process and need to be processed manually to become qualified The product is put on the belt conveyor 7 to carry out sewing and post-section processing, and an automatic counter 9 is set at the end of the belt conveyor 7, and what the automatic counter 9 records is the quantity of qualified products, and the data is more accurate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com