Packaging structure and packaging method of oled devices

A packaging structure and device technology, applied in the field of devices, can solve the problems of reduced packaging efficiency, package cover slippage and offset, and packaging accuracy cannot be guaranteed, so as to improve packaging efficiency, avoid slippage and offset, and adapt The effect of large-scale promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

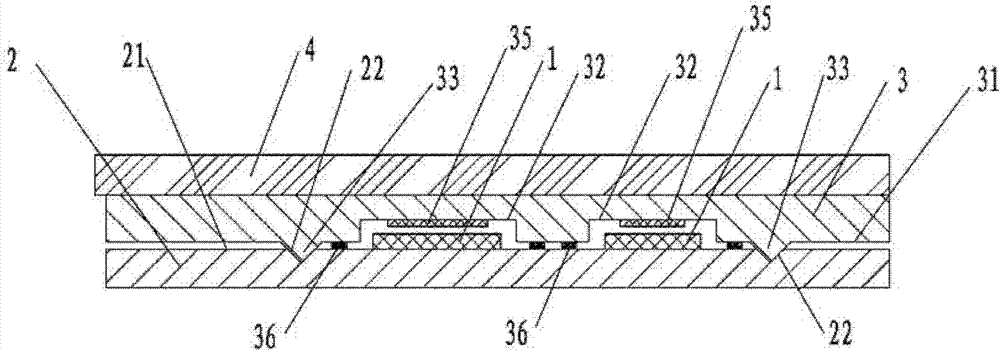

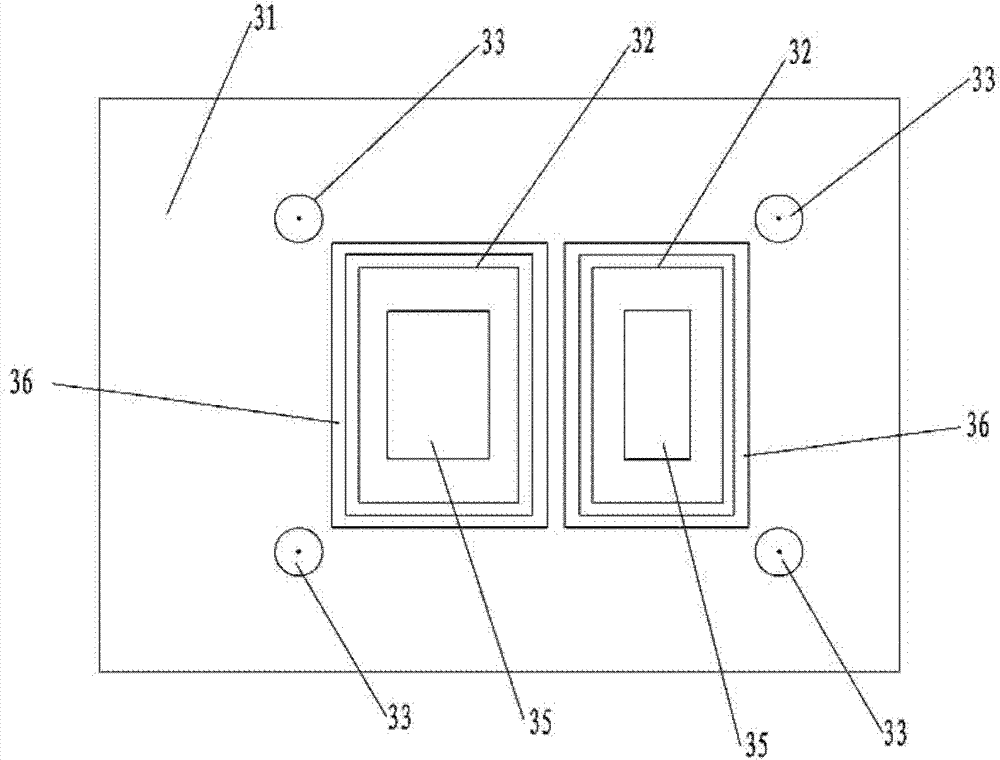

[0027] Such as figure 1 As shown, the packaging structure of the OLED device of the present invention includes a display substrate 2 for supporting the OLED device 1, a packaging cover plate 3 that is combined with the display substrate 2 and seals the OLED device 1, and bonded to the packaging cover plate 3. A packaging pressing device 4 for pressing the packaging cover plate 3 and the display substrate 2 . A first engaging portion is provided on the supporting joint surface of the display substrate 2 , and a second engaging portion matched with the first engaging portion is provided on the packaging joint surface of the package cover 3 combined with the supporting joint surface.

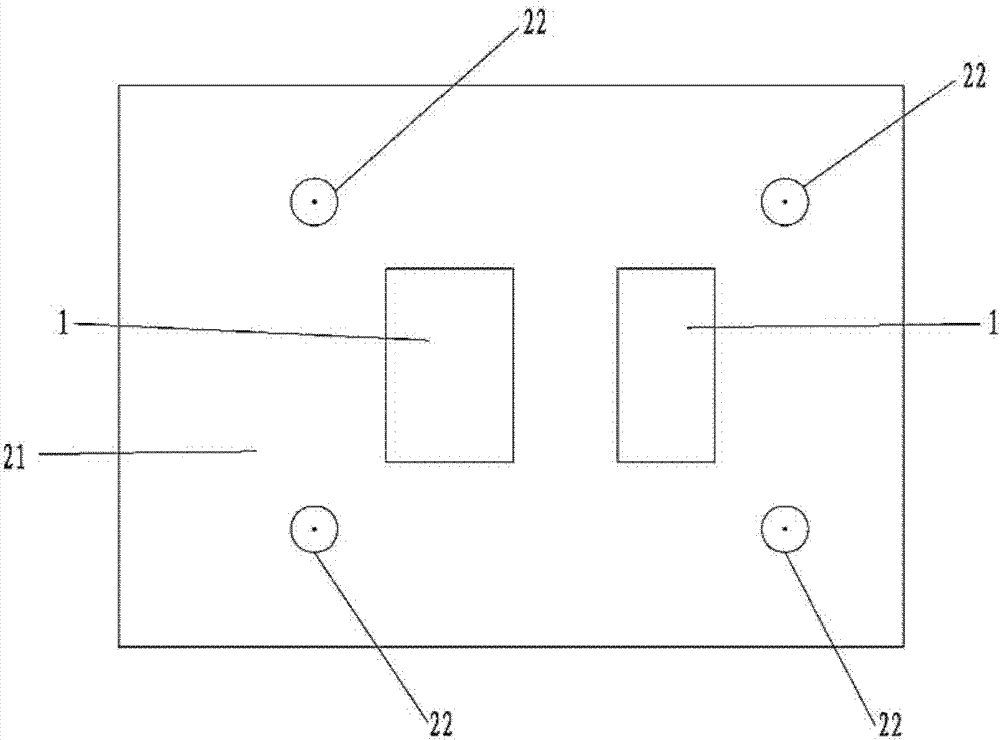

[0028] combine figure 2 As shown, the first surface 21 of the rectangular display substrate 2 serves as a supporting joint surface for supporting the OLED device 1 and combining with the package cover 3 . The OLED device 1 is bonded to a specific position approximately in the center of the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com