Flushing executing mechanism for vacuum closestool

A technology of an actuator and a vacuum toilet, which is applied to flushing equipment with water tanks, cabin flushing devices, flushing toilets, etc., can solve the problems of vacuum toilet volume limitation, increase equipment volume, limited space, etc., to reduce occupied space and disassemble Simple maintenance and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

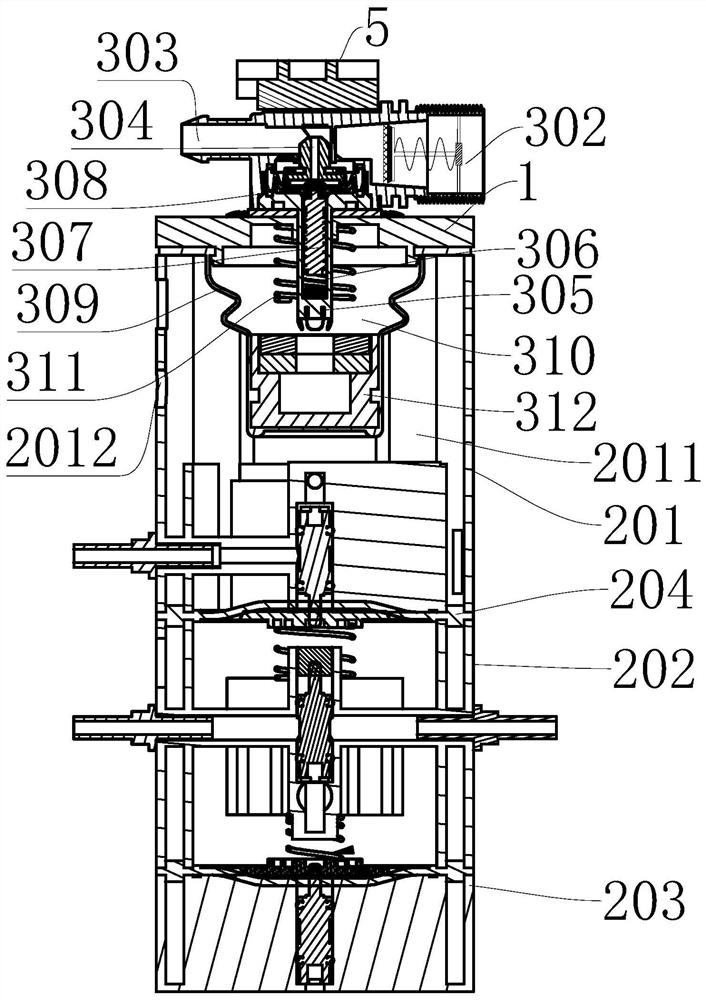

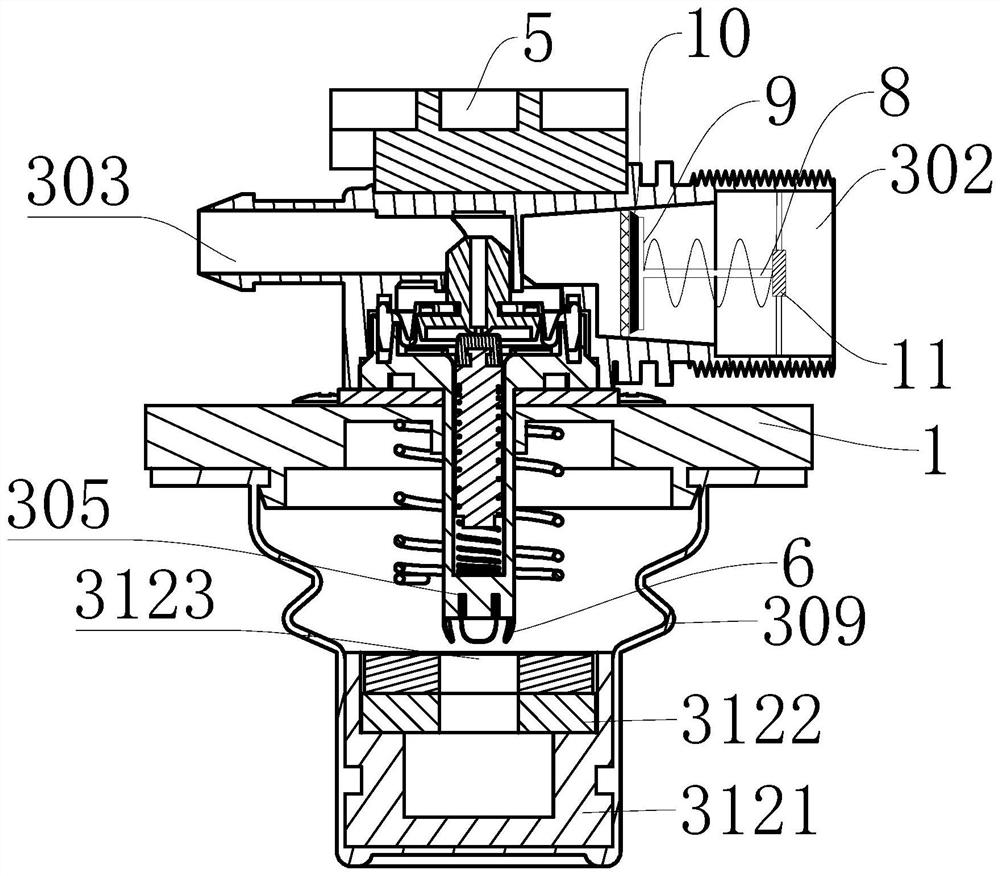

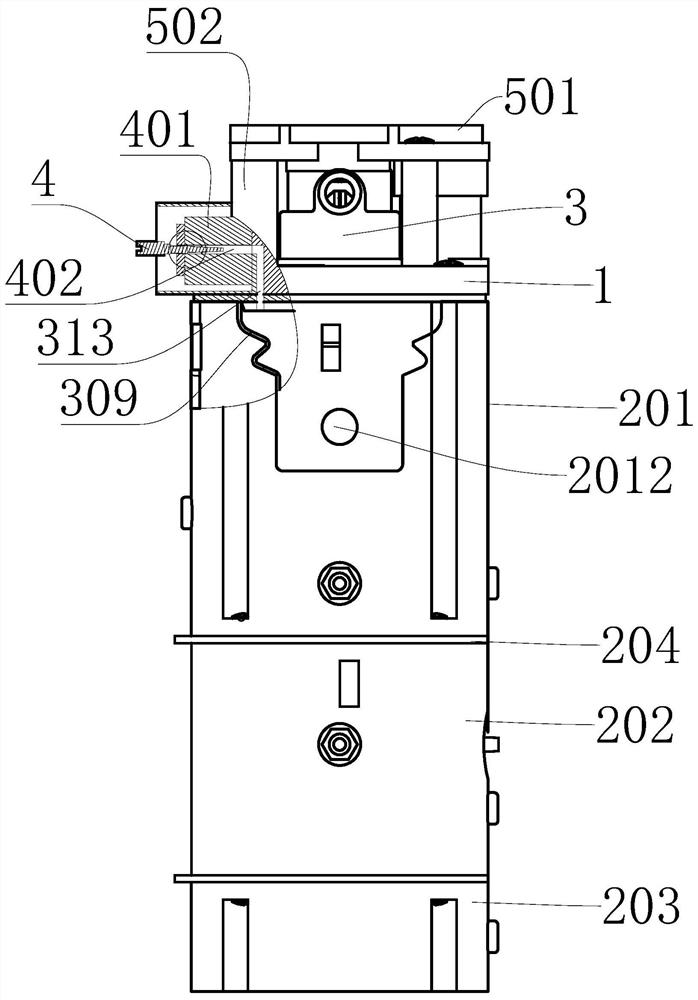

[0025] Such as Figure 1-5 As shown, this embodiment discloses a flushing actuator for a vacuum toilet, including a top cover 1 and an actuator body 2, the top cover 1 is arranged on the actuator body 2, and the feature is that the top cover 1 is provided with a water valve assembly 3, the water valve assembly 3 includes a valve body 301 arranged on the side of the top cover 1 away from the actuator body 2, the valve body 301 is symmetrically provided with a water inlet 302 and a water outlet 303, A water pipe 304 is provided between the water inlet 302 and the water outlet 303, and the valve body 1 is also provided with a first valve stem 305 that passes through the top cover 1 and is exposed in the actuator body 2. The valve stem 305 is provided with an installation chamber 306 communicating with the water passage 304, and the installation chamber 306 is e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com