Foamed ceramic modeling line fixing assembly, fixing method and fixing structure thereof

A technology of foamed ceramics and fixed components, which is applied in building structure, construction, etc., can solve the problems of weak bonding and easy damage of foamed ceramic modeling lines, and achieve reliable resistance to horizontal loads, reliable force, and guaranteed installation. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

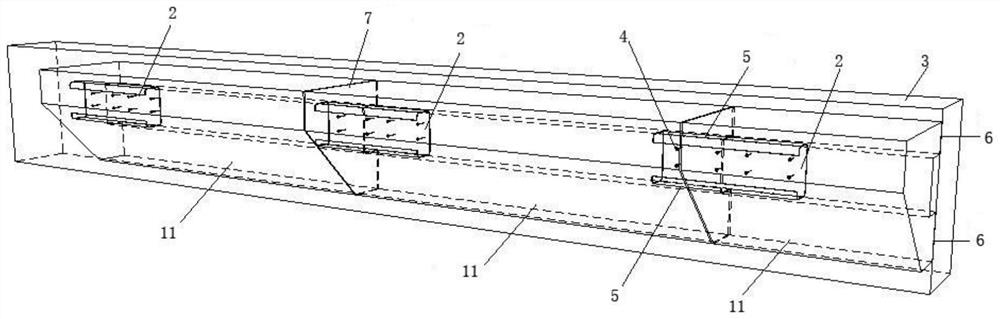

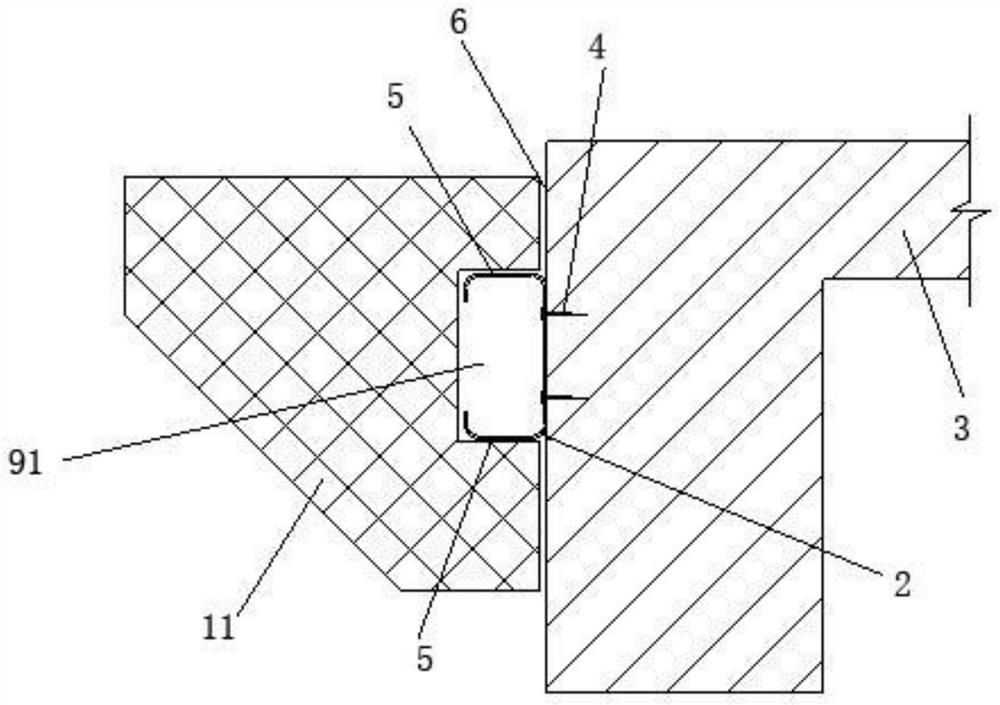

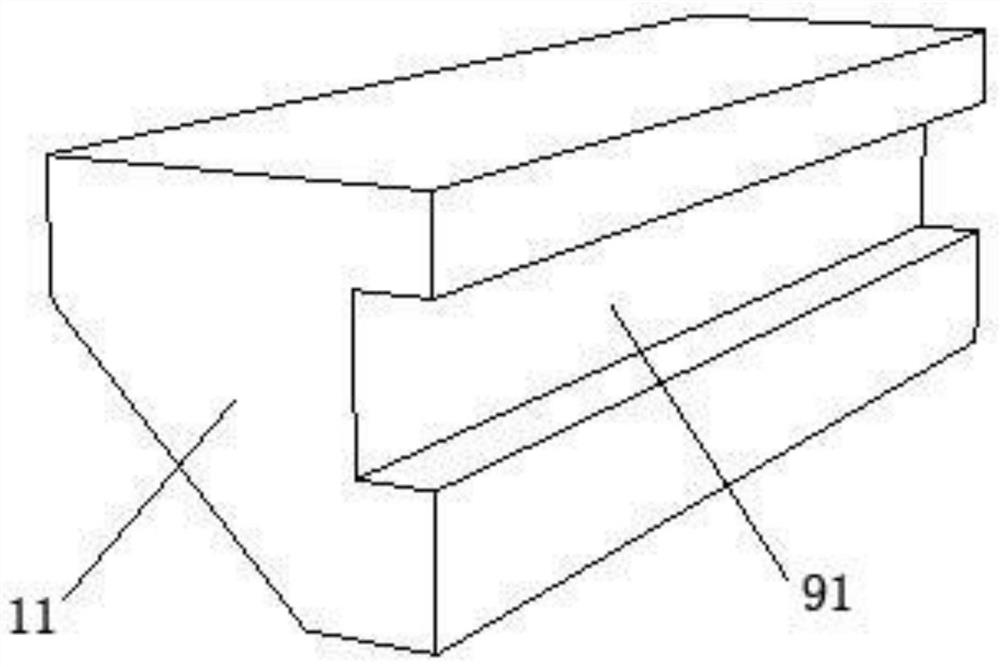

[0042] Such as Figure 1-4 As shown: the foamed ceramic lines are horizontal foamed ceramic lines 11 , and the limiting grooves on the back of the horizontal foamed ceramic lines 11 are through grooves 91 extending along the extending direction of the horizontal foamed ceramic lines 11 .

Embodiment 2

[0044] Such as Figure 8-11 As shown: the foamed ceramic lines are vertical foamed ceramic lines 12 , and the back of the vertical foamed ceramic lines 12 is provided with a non-penetrating groove 92 corresponding to the metal fixing part 2 .

[0045] In Embodiment 2, both sides of the upper support plate 22 and the lower support plate 23 in the metal fixture 2 are connected to each other through side end plates 24 . This can increase the strength of the metal fixing part 2 .

[0046] The locking piece is an anchor piece 4 . Through the anchors 4 arranged in an array, a firm connection between the metal fixing part 2 and the main structure 3 can be realized.

[0047] Such as Figure 5-7 , Shown in 12-14: the fixing method of the above-mentioned foamed ceramic molding line fixing assembly is as follows: it includes the following steps:

[0048] Step 1: Fix the metal fixing part 2 to the main structure 3 using the anchor part 4 arranged in an array;

[0049] Step 2: Insert ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap