Power recovery method and implementation device of high back pressure diesel engine based on electric supercharging

A technology of power recovery and electric boosting, which is applied in combustion engines, engine control, machines/engines, etc., can solve the problems of no patents, etc., and achieve the effects of simple structure, power realization, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

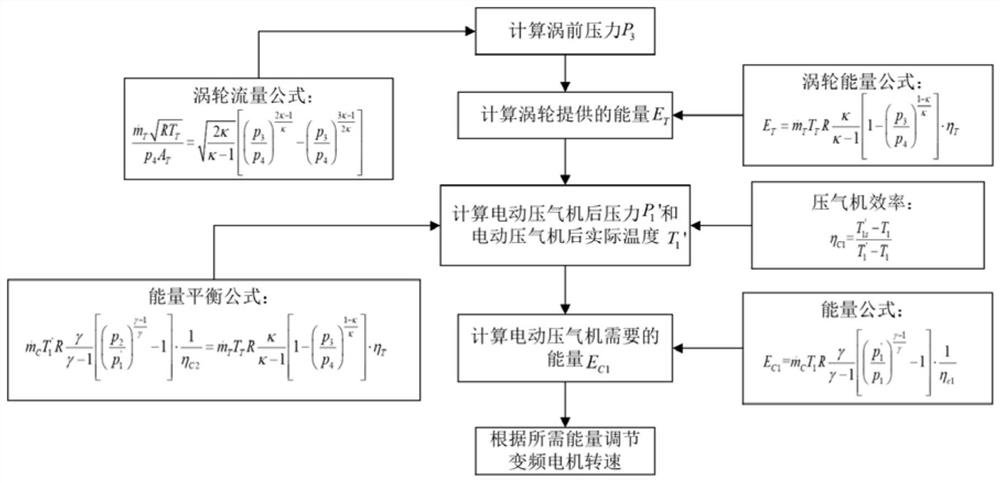

Method used

Image

Examples

Embodiment

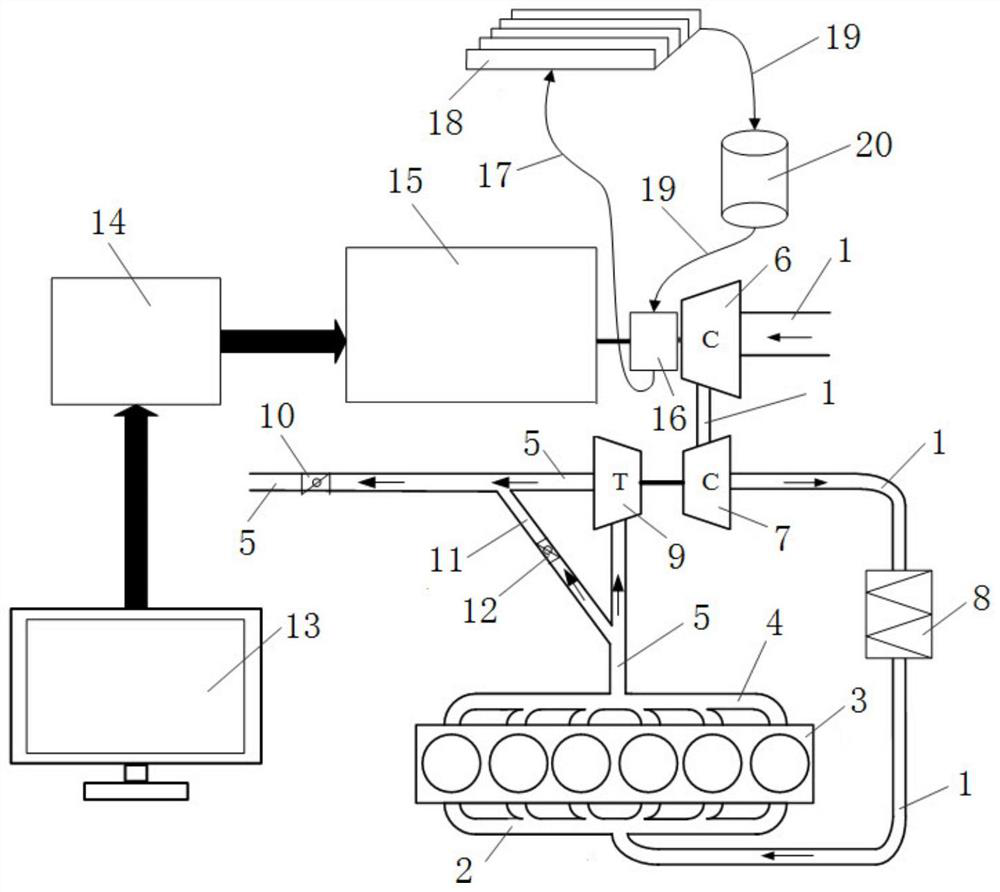

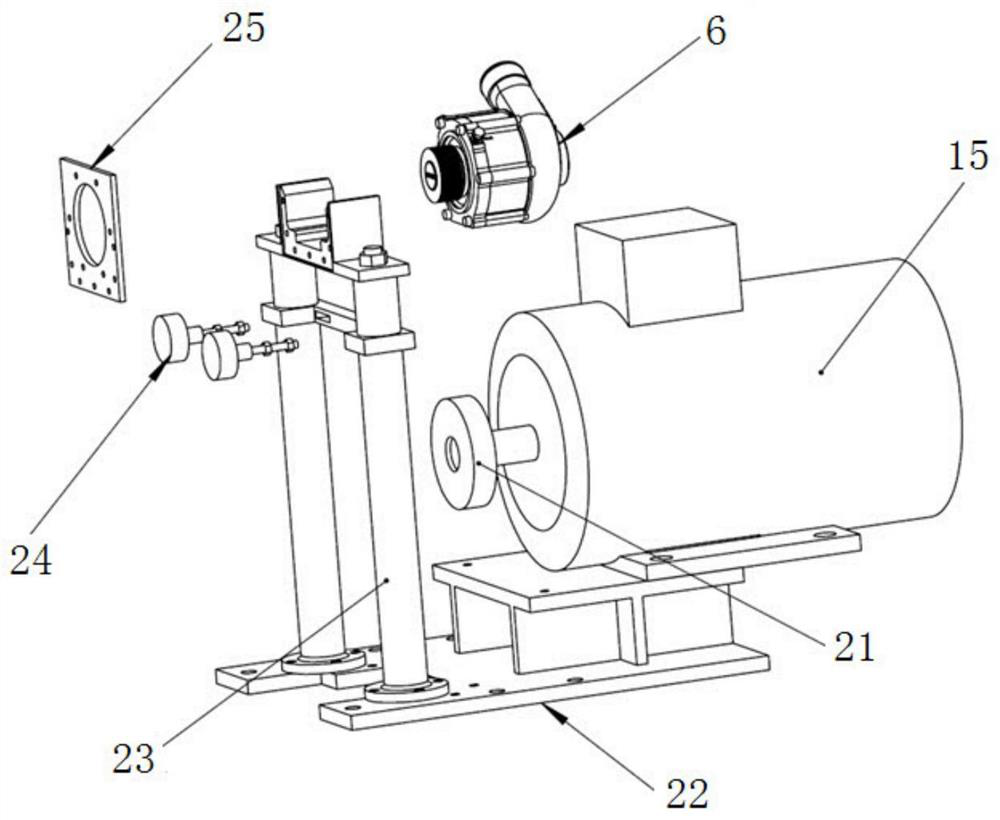

[0030] The specific structure of the entire implementation device is as follows: figure 2 and image 3 As shown, it includes intake manifold 1, intake manifold 2, diesel engine 3, exhaust manifold 4, exhaust manifold 5, electric compressor 6, compressor 7, intercooler 8, turbine 9, exhaust back pressure valve 10 , bypass pipe 11, bypass valve 12, host computer 13, control module 14, frequency conversion motor 15, gear box 16, gear box oil outlet pipe 17, heat sink 18, gear box oil inlet pipe 19, cooling oil tank 20, motor pulley 21. Mounting base 22, electric compressor bracket 23, tensioner 24, electric compressor fixing plate 25, the inlet of the intake branch pipe 2 is connected to the outlet of the intake manifold 1, and the outlet of the intake branch pipe 2 is connected to the diesel engine 3 inlet. The inlet of the air passage is connected, the inlet of the exhaust branch pipe 4 is connected with the outlet of the exhaust passage of the diesel engine 3, the outlet of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com