Drying device for grain production and working method thereof

A drying device and grain technology, applied in drying, drying machines, heating devices, etc., can solve the problems of low drying efficiency, inability to dry grain, inconvenient filtration of dust or weeds, etc., and increase the heating area , Improve drying efficiency and reduce damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

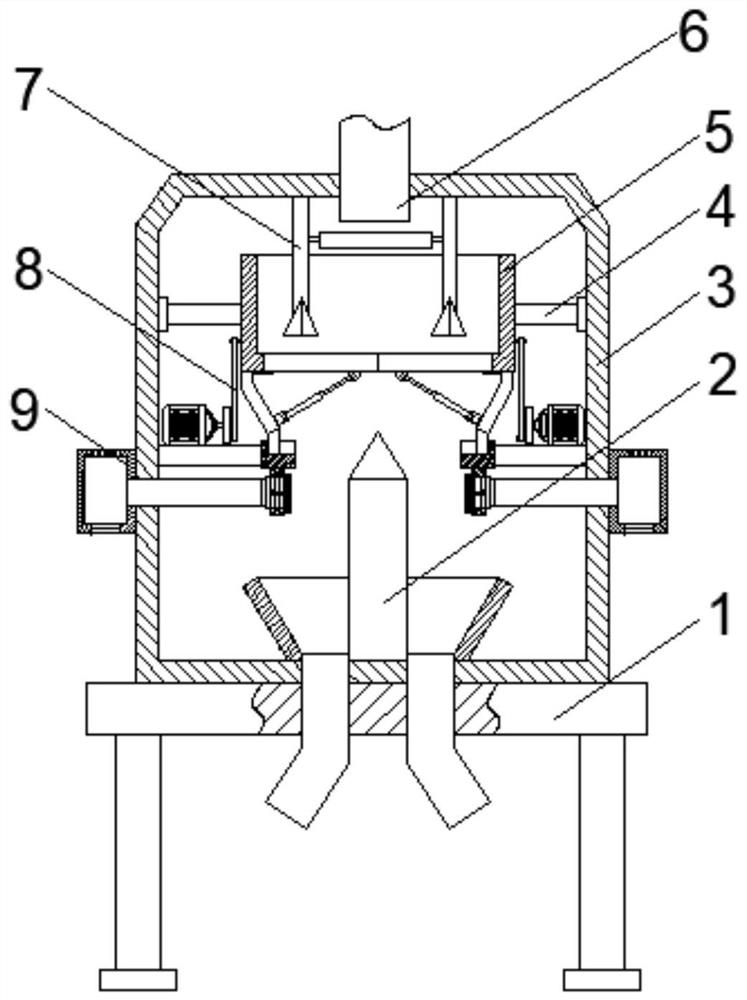

Embodiment 1

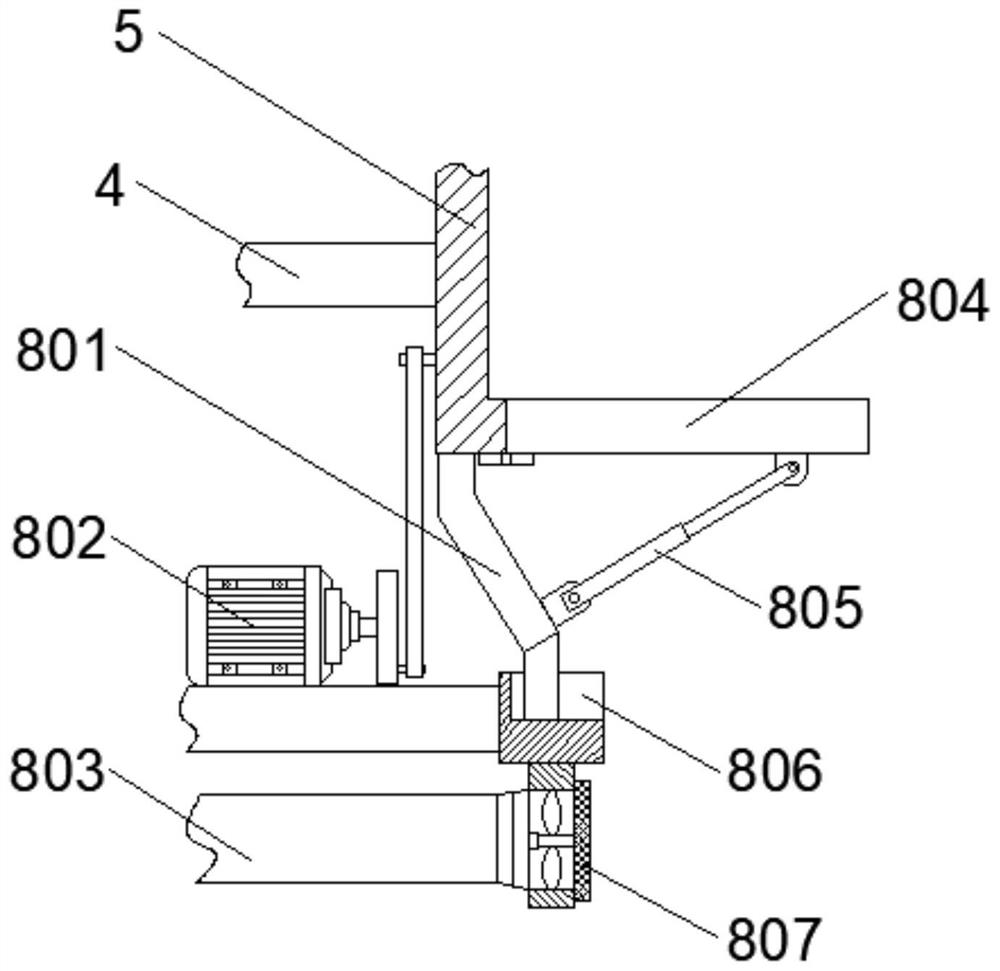

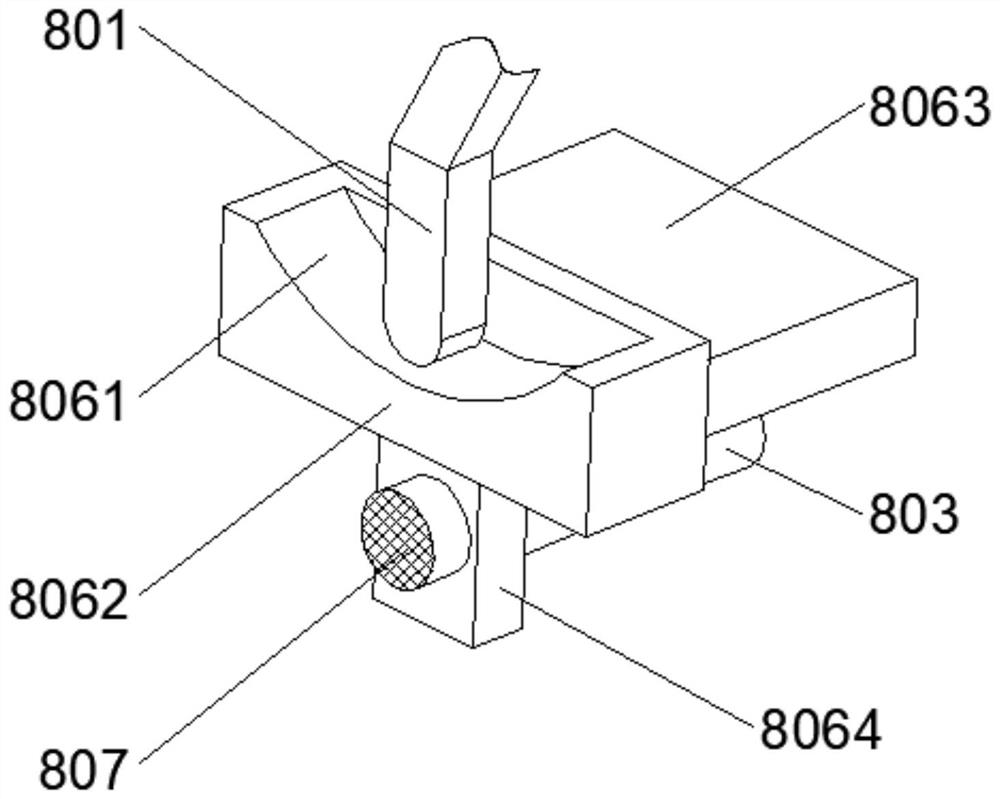

[0034] see figure 2As shown, the above-mentioned rocking mechanism 8 includes a support frame 801 fixedly connected to the bottom of the storage box 5. The middle part of the support frame 801 is hinged with an electric push rod 805. The bottom surface of the storage box 5 is provided with a discharge hole. The extension of the electric push rod 805 The outlet is hinged with a door 804, and one end of the door 804 is hinged with the storage box 5, and the door 804 is opened or closed by an electric push rod 805, so that it is convenient to control the grain for the next production and processing process and reduce labor costs. In the process of operation, the two sides of the storage box 5 are fixedly connected with the rotating shaft 4, and the two rotating shafts 4 are connected to the shell 3 through bearings, and the storage box 5 is conveniently limited by the rotating shaft 4 to prevent the storage box 5 from falling. In this case, the bottom of the support frame 801 is...

Embodiment 2

[0039] see Figure 5 As shown, the above-mentioned drying mechanism 7 includes two first fixed rods 702 that are fixedly connected to the top of the inner wall of the housing 3, and the bottom ends of the two first fixed rods 702 are fixedly equipped with a partition block 703, and the two first fixed rods The middle part of 702 is fixedly connected with a mounting plate 705, and the two mounting plates 705 are fixedly connected by several electric heating rods 701, and the food in the storage box 5 is separated and mixed through the partition block 703, and then passed through several electric heating rods. 701 to dry it efficiently, one end of the two mounting plates 705 is fixedly connected with a second fixed rod 704, and the tops of the two second fixed rods 704 are fixedly connected with the top of the inner wall of the shell 3, and several electric heating rods 701 A feeding pipe 6 is arranged above the top of the feeding pipe 6 , and the top end of the feeding pipe 6 r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com