Bearing composite fault diagnosis method based on improved local non-negative matrix factorization

A non-negative matrix decomposition, composite fault technology, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., to achieve the effect of improving independence and optimal decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0102] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

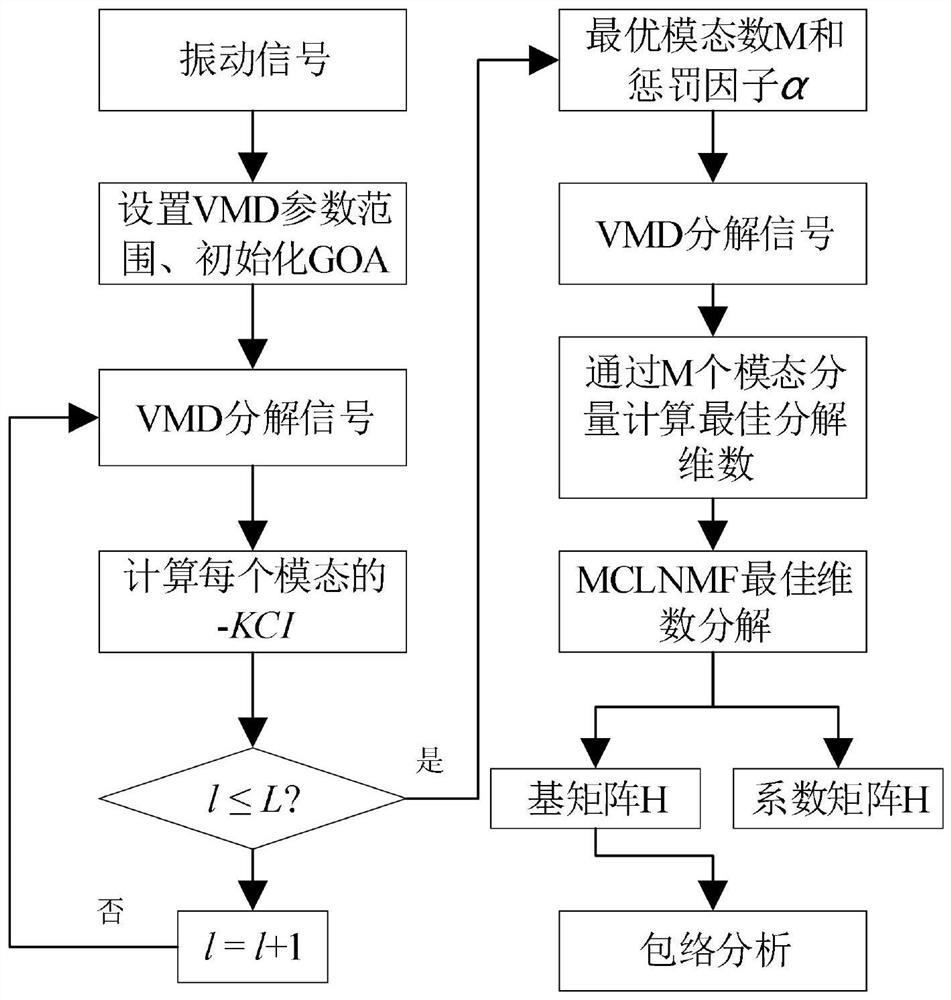

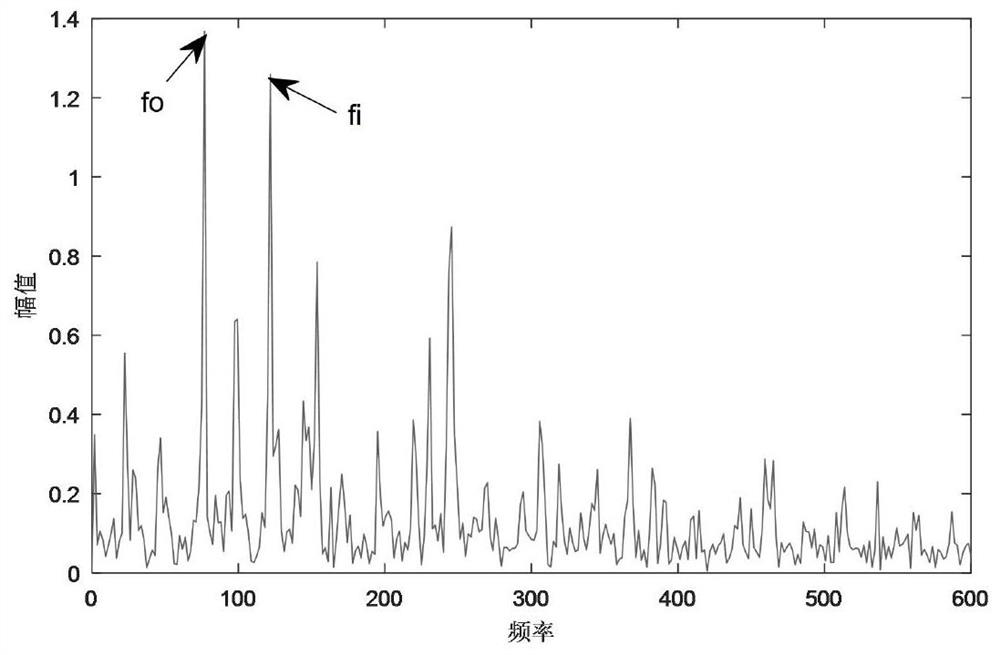

[0103] figure 1 It is a flow chart of the bearing compound fault diagnosis method based on minimum correlation local non-negative matrix decomposition of the present invention. The principle of the bearing compound fault diagnosis method proposed by the present invention will be described in detail below in conjunction with the flow chart.

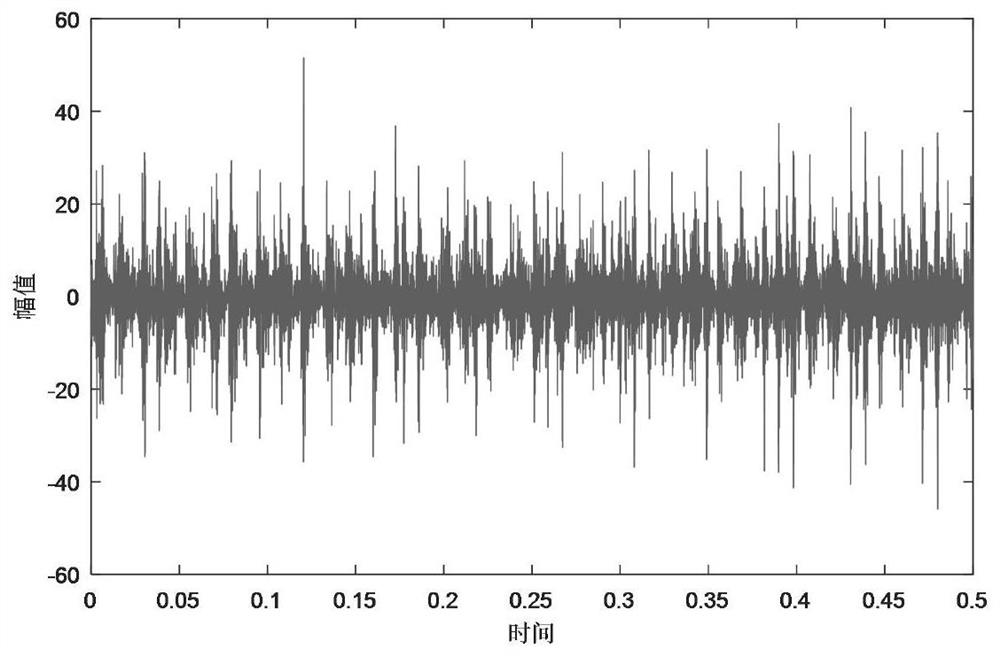

[0104] (1) Use the sensor to measure the faulty bearing test bench, and obtain the vibration signal as the initial input signal;

[0105] (2) the VMD parameter range to be optimized is set, and the GOA parameter is initialized, including the maximum number of iterations L=20 and the search agent n=30;

[0106] (3) Use VMD to decompose the vibration signal and calculate the fitness of each mode. Save the minimum fitness of each GOA iteration, which is the opposite number of the maximum correlation kurtosi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com