Drilling and sampling equipment for engineering detection

A sampling equipment and engineering detection technology, applied in the direction of sampling devices, etc., can solve the problems of unsuitable concrete sampling, damage to the original state of concrete, inconvenient detection and other tests, and achieve simple and efficient sampling operation, convenient and fast separation, and well-preserved shape Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

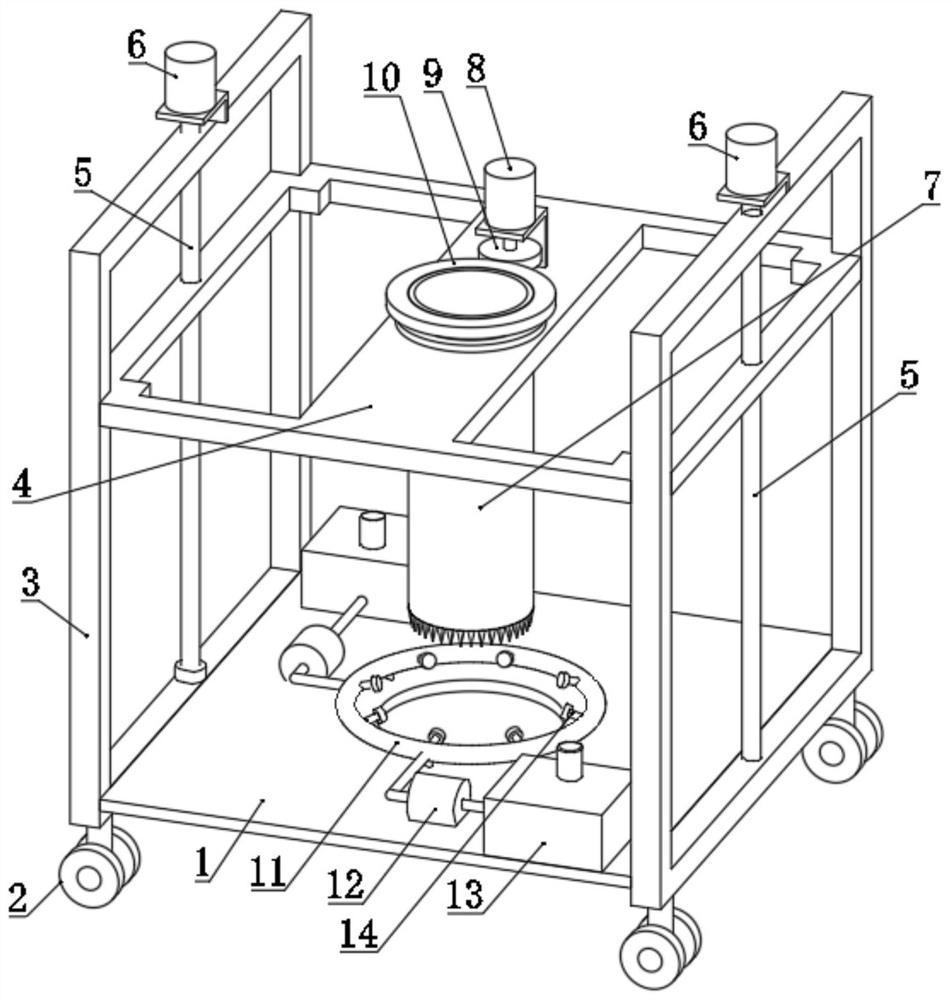

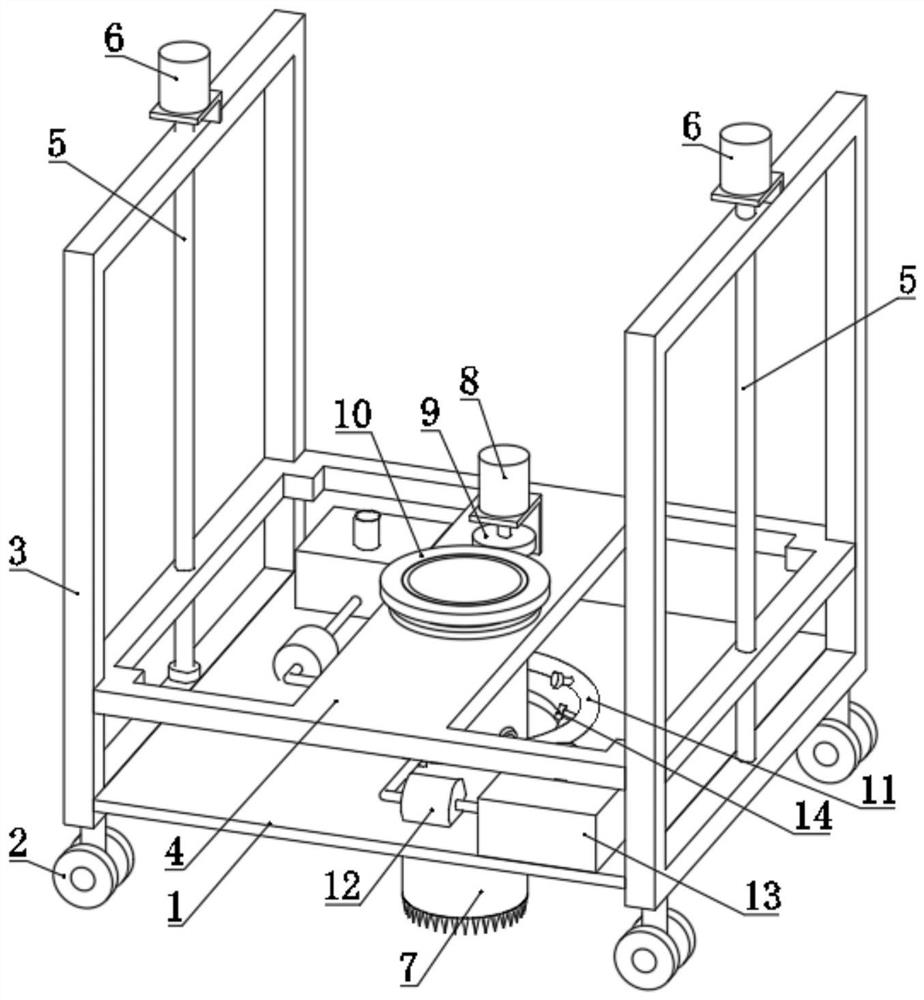

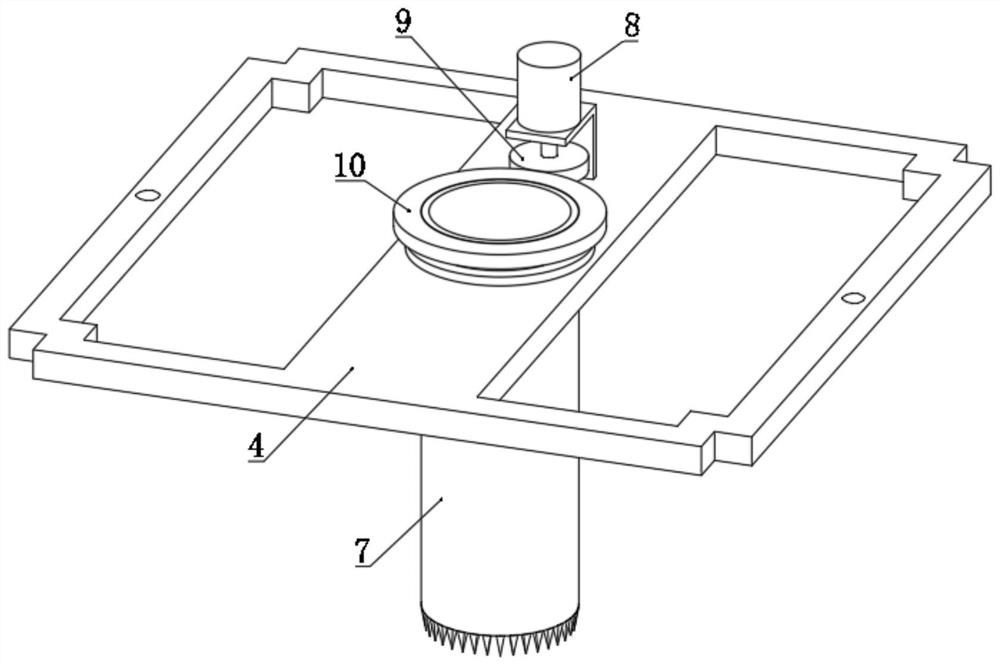

[0031] refer to Figure 1-3 , a drilling sampling device for engineering testing, comprising a base 1, a stand 3 is symmetrically installed on the upper side of the base 1, a plurality of universal wheels 2 are installed on the lower side of the base 1, and a lifting plate is provided on the upper side of the base 1 4. The two ends of the lifting plate 4 are slidingly installed with the stand 3 respectively, and the stand 3 is rotated and installed with a lifting screw 5, which is threadedly installed with the lifting plate 4, and the lifting screw 5 is driven by the lifting motor 6, and the lifting Screw mandrel 5 is two, and two lifting screw mandrels 5 are threadedly installed with the two ends of lifting plate 4 respectively, and two lifting screw mandrels 5 are driven by lifting motor 6 respectively.

[0032] The lifting plate 4 is rotated and installed with a sampling drum 7. The sampling drum 7 is driven by a drive motor 8. The bottom of the sampling drum 7 is provided ...

Embodiment 2

[0040] refer to Figure 4-6 , present embodiment 2 is on the basis of above-mentioned embodiment 1, offers threaded hole in the inside of one side of sampling drum 7, and is installed with clamping screw rod 15 through threaded hole thread, the inner wall of sampling drum 7 and is positioned at threaded hole. One side of the bottom of the hole is provided with a slotted hole 16, and the bottom end of the clamping screw rod 15 extends into the slotted hole 16, and the side of the slotted hole 16 near the center of the sampling drum 7 is rotated by a rotating shaft 18 to install a clamping block 17, the clamping block One side of 17 is in frictional contact with the bottom end of the clamping screw rod 15 .

[0041] Such as Figure 5 As shown in , two limit rings 20 are symmetrically installed on the outside of the top of the sampling drum 7 , and the two limit rings 20 are slidably attached to the top surface and the bottom surface of the lifting plate 4 respectively.

[0042] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com