Blast furnace sintered ore particle size detection method and system based on RGB and laser feature fusion

A technology of feature fusion and detection method, applied in neural learning method, character and pattern recognition, image data processing and other directions, can solve the problem of low detection accuracy of blast furnace sinter particle size, and achieve the effect of improving segmentation accuracy and detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] The blast furnace sinter particle size detection method based on fusion of RGB and laser features provided by Embodiment 1 of the present invention includes:

[0073] Step S101, collecting RGB images of blast furnace sintered ore on the blast furnace charge conveyor belt and single-line laser detection data to obtain RGB data sets and laser data sets;

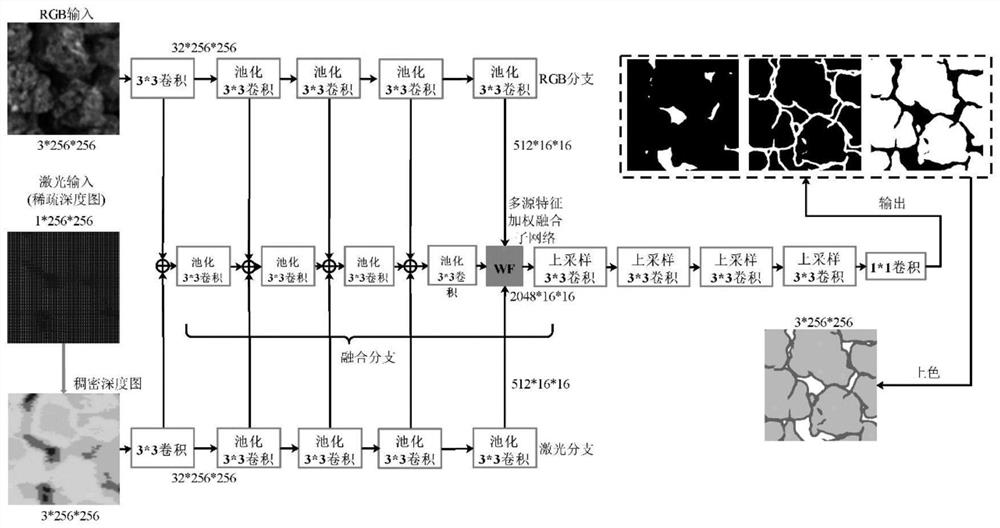

[0074] Step S102, constructing a deep learning network with an encoder-decoder structure, the deep learning network includes an RGB encoding branch, a laser encoding branch, a fusion branch and a decoding process;

[0075]Step S103, according to the RGB coding branch and the laser coding branch, respectively perform feature extraction on the RGB data set and the laser data set, and obtain RGB initial feature tensors and laser initial feature tensors;

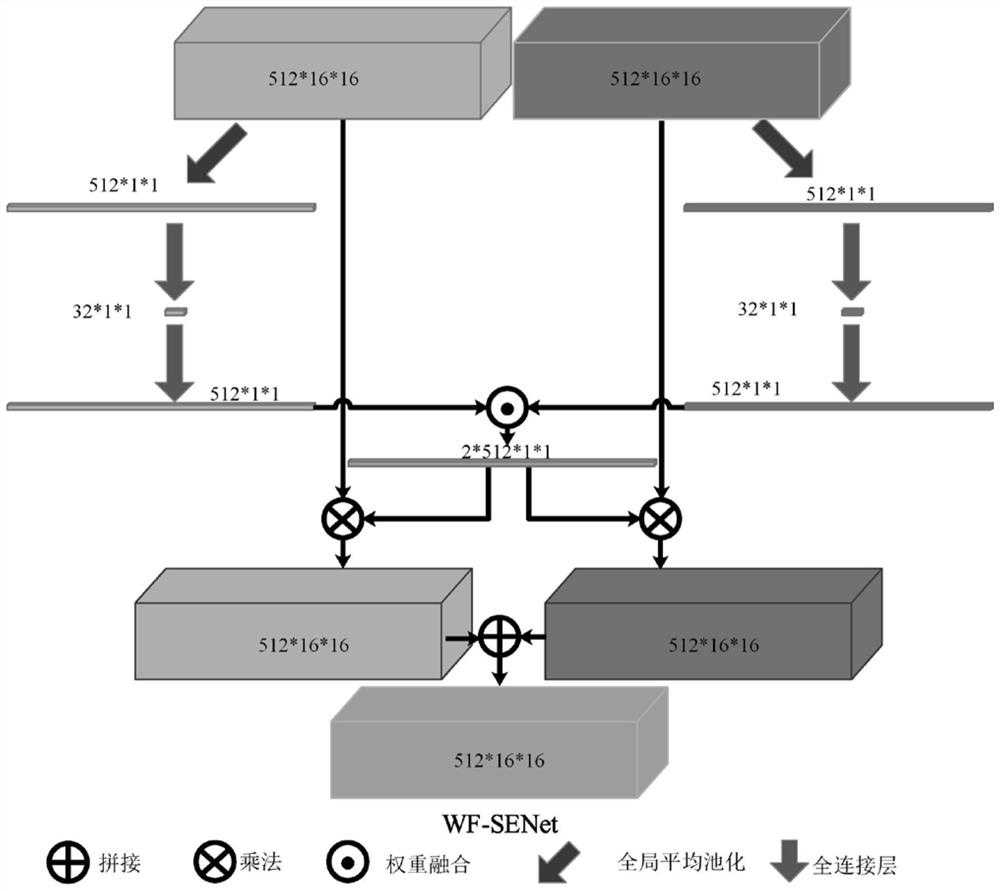

[0076] Step S104, constructing a multi-source feature weighted fusion sub-network in the last layer of the fusion branch, and based on the multi-source feature weighted fu...

Embodiment 2

[0080] The blast furnace sinter particle size detection method based on RGB and laser feature fusion in the embodiment of the present invention includes:

[0081] Step S201, collecting RGB images of blast furnace sintered ore on the blast furnace charge conveyor belt and single-line laser detection data to obtain RGB data sets and laser data sets.

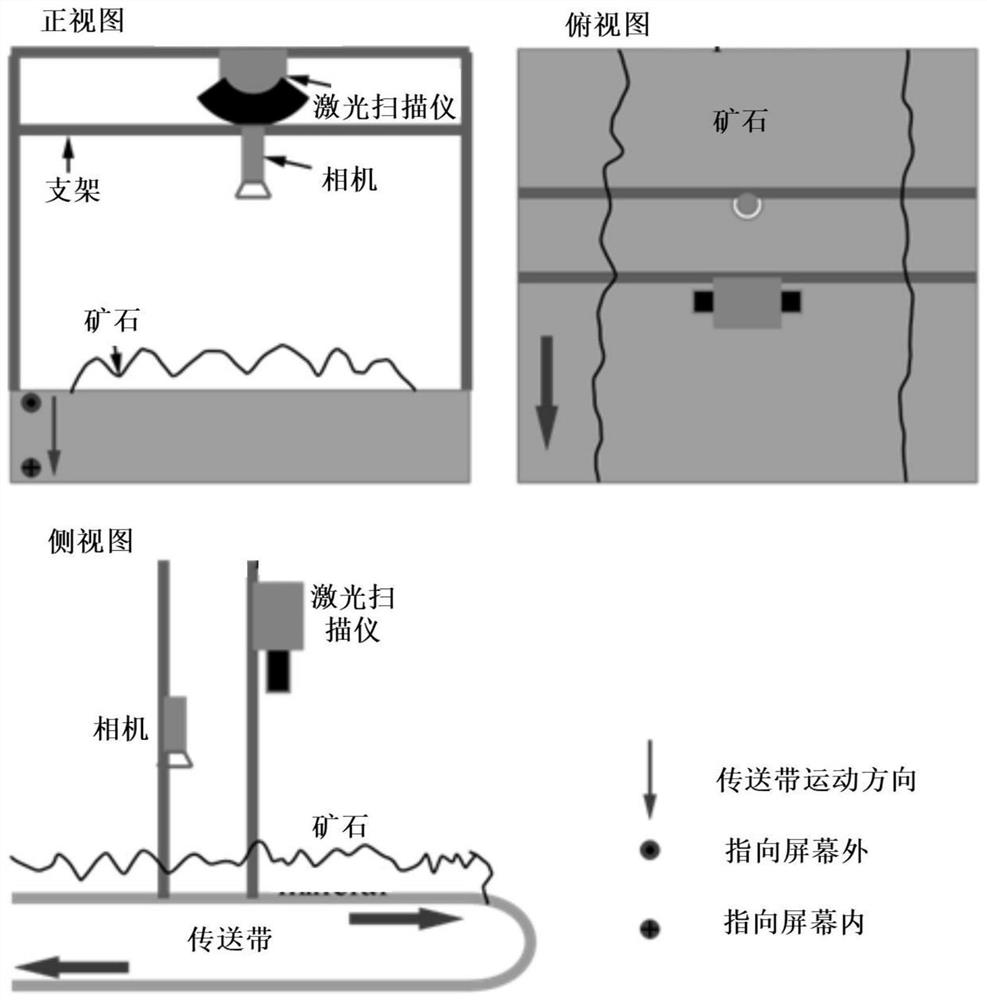

[0082] Specifically, in order to obtain high RGB images and Laser detection data, RGB image information and Laser depth information are collected through hardware devices such as industrial cameras and laser scanners. Among them, the laser detection equipment is the LMS4111R-13000 laser line scanner produced by SICK, and the data acquisition software is SOPAS Engineering Tool. The industrial camera is the German Basler acA2500-14gm Basler industrial area array camera data acquisition software is pylon Viewer. Both use Ethernet to communicate. Acquisition system such as figure 1 as shown, figure 1 In the embodiment of the presen...

Embodiment 3

[0134] In this embodiment, the 2650m in a certain ironworks 3 The specific steps of the blast furnace ore image segmentation method based on the weighted fusion of RGB and laser features are as follows:

[0135] 1. Data set production. In order to obtain RGB images of blast furnace sinter and Laser detection data, the present invention collects RGB image information and Laser depth information through hardware devices such as industrial cameras and laser scanners on the blast furnace feeding belt of a steel plant. Among them, the laser detection equipment is the LMS4111R-13000 laser line scanner produced by SICK, and the data acquisition software is SOPAS Engineering Tool. The industrial camera is the German Basler acA2500-14gmBasler industrial area array camera data acquisition software is pylon Viewer. Both use Ethernet to communicate. A total of 8 sets of data are collected in a concentrated period of time by industrial cameras and laser scanners (each time a set of data...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com