Semiconductor cleaning method and cleaning equipment

A technology for cleaning equipment and semiconductors, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc. It can solve the problems that affect the performance of semiconductor devices, and semiconductor devices are easy to produce particles, so as to avoid the effect of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

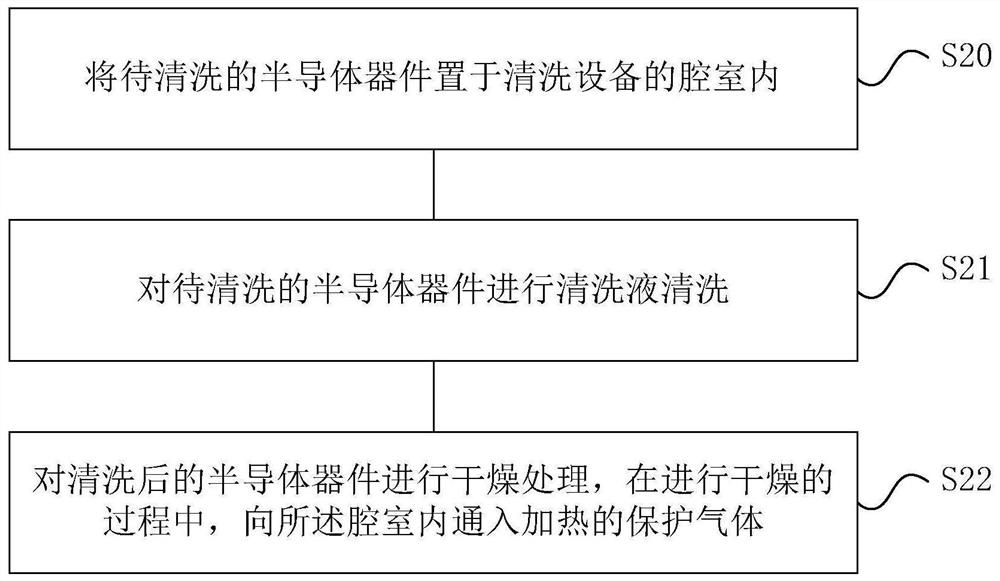

[0026] The specific implementations of the semiconductor cleaning method and cleaning equipment provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

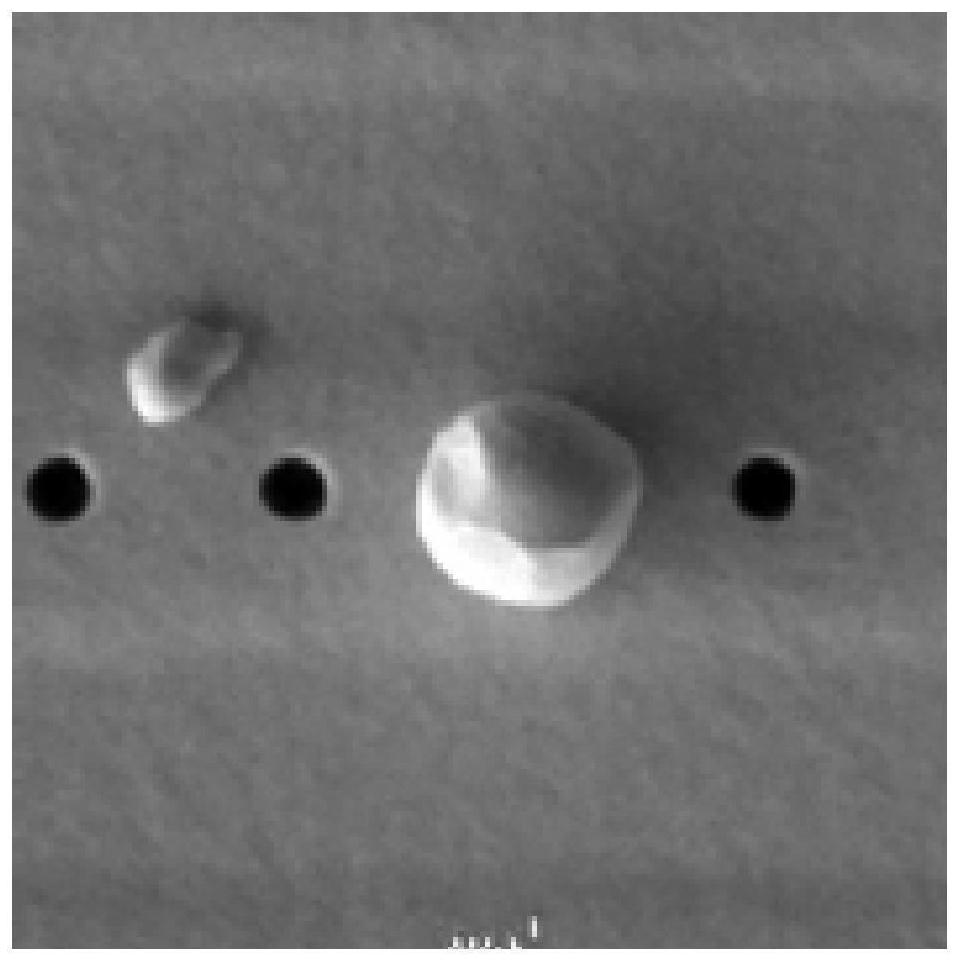

[0027] As mentioned in the background, during the manufacturing process of semiconductor devices, the process of cleaning the semiconductor devices is often involved. The inventors found that after the cleaning process, particles tend to adhere to the surface of the semiconductor device, and the particles will affect the subsequent manufacture of the semiconductor device. figure 1 is the scanning electron microscope image of the surface of the semiconductor device after the cleaning treatment step, from figure 1 It can be seen that particles are attached to the surface of the semiconductor device.

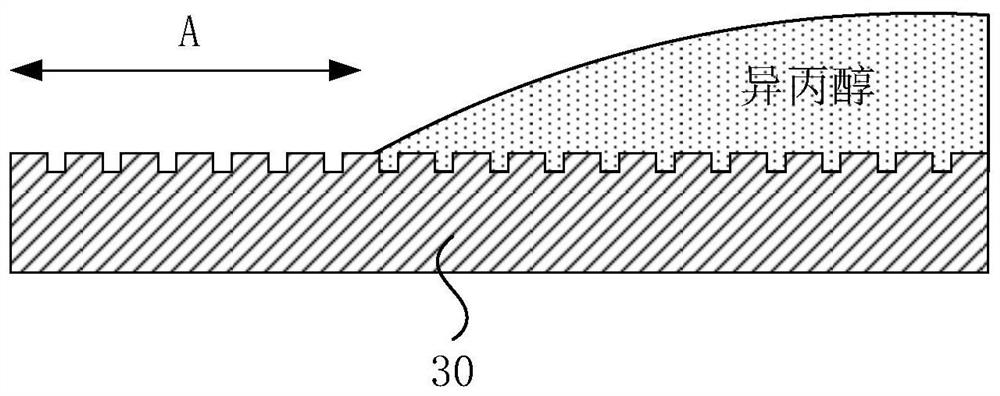

[0028] The inventors further found that the particles exist in the form of solid matter or condensed liquid droplets. The inventor conducted a lot of research and analys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com