Mode control semiconductor device and preparation method thereof

A mode control and semiconductor technology, applied in the direction of semiconductor lasers, optical waveguide semiconductor structures, lasers, etc., can solve the problem of power coupling loss, increased failure of light-emitting semiconductor devices, and increased power density that cannot be improved at the same time as the anti-optical catastrophe damage threshold of the front cavity surface and other issues, to achieve the effects of cost reduction, reduced coupling loss, and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

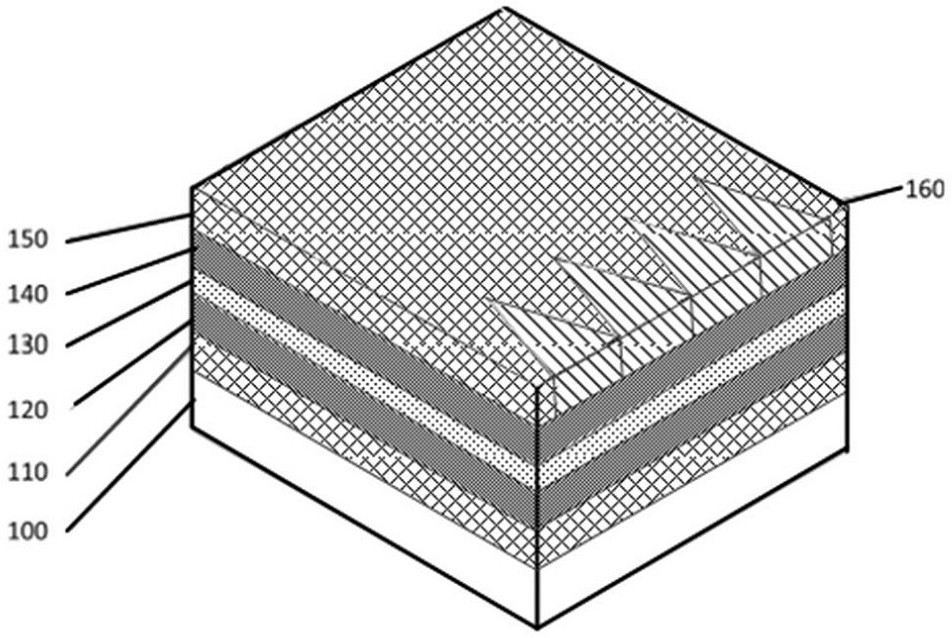

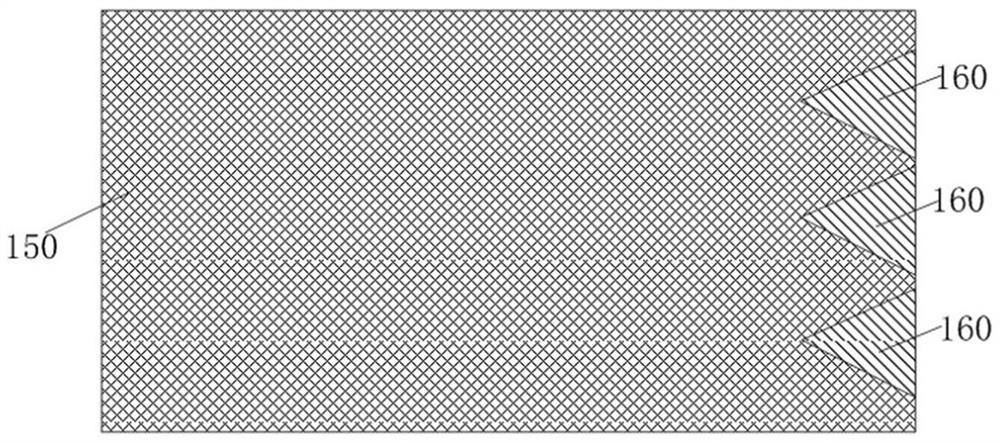

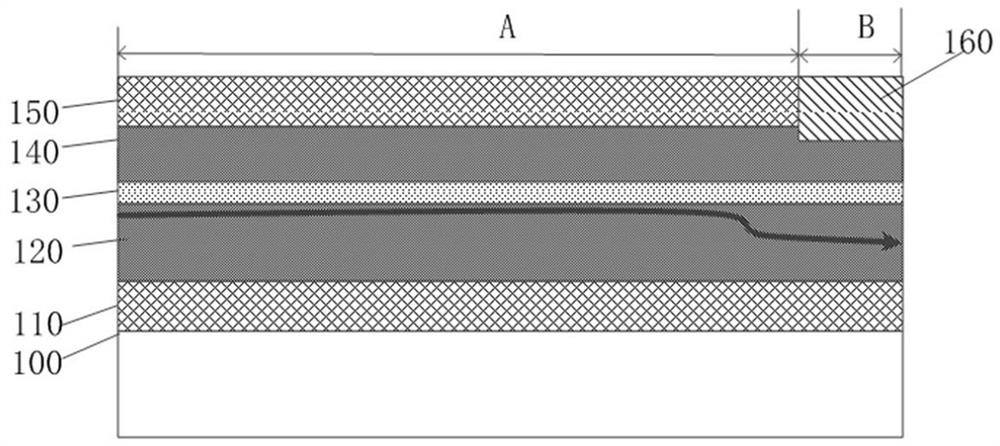

Embodiment Construction

[0032] Light-emitting semiconductor devices are more prone to damage in the active gain region of the cavity surface when the optical power output is high. In order to solve the problem of increased failure of light-emitting semiconductor devices due to optical catastrophe damage on the cavity surface, a method includes: passivating the cavity surface by ultra-high vacuum cleavage, and forming a window structure on the cavity surface in a hybrid way to improve the cavity surface damage resistance. However, these current solutions have extremely strict requirements on the control of process equipment and process conditions, which increases the process complexity and cost of light-emitting semiconductor device production. Another method includes: increasing the power by reducing the optical confinement of the gain material through the design of the epitaxial structure of the chip. However, this method will increase the threshold of the light-emitting semiconductor device and red...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap