Chimney device for capturing and recovering CO2

A CO2 and chimney technology, applied in the separation of dispersed particles, air quality improvement, chemical instruments and methods, etc., can solve the problems of high equipment cost and equipment maintenance cost, reduce input costs and maintenance costs, huge economic value, and have The effect of promoting the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The technical characterictic of the present invention is described below in conjunction with accompanying drawing by specific embodiment:

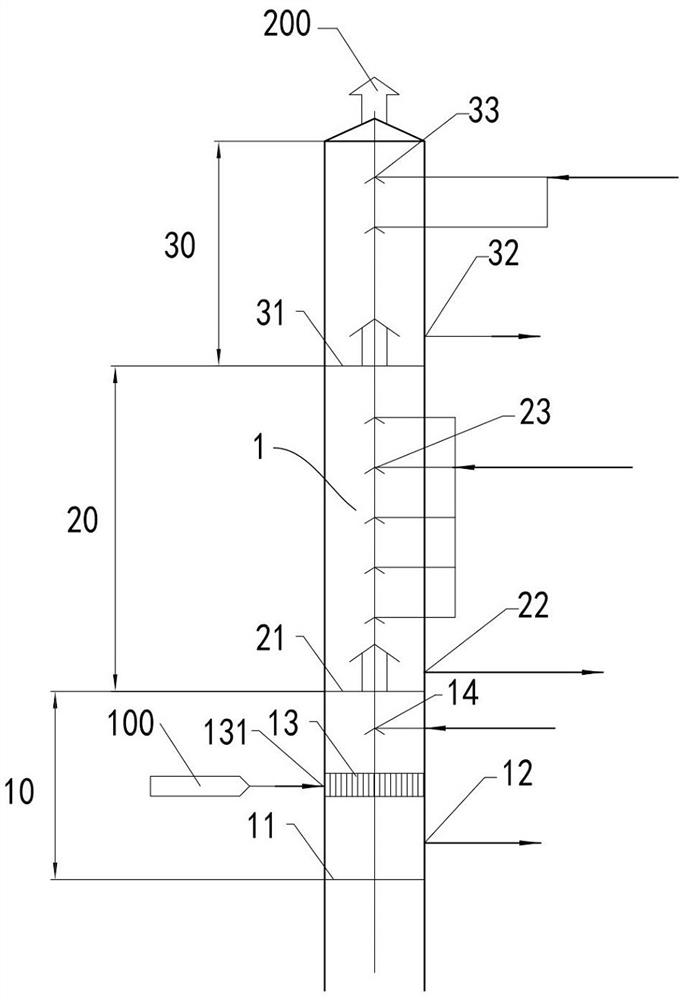

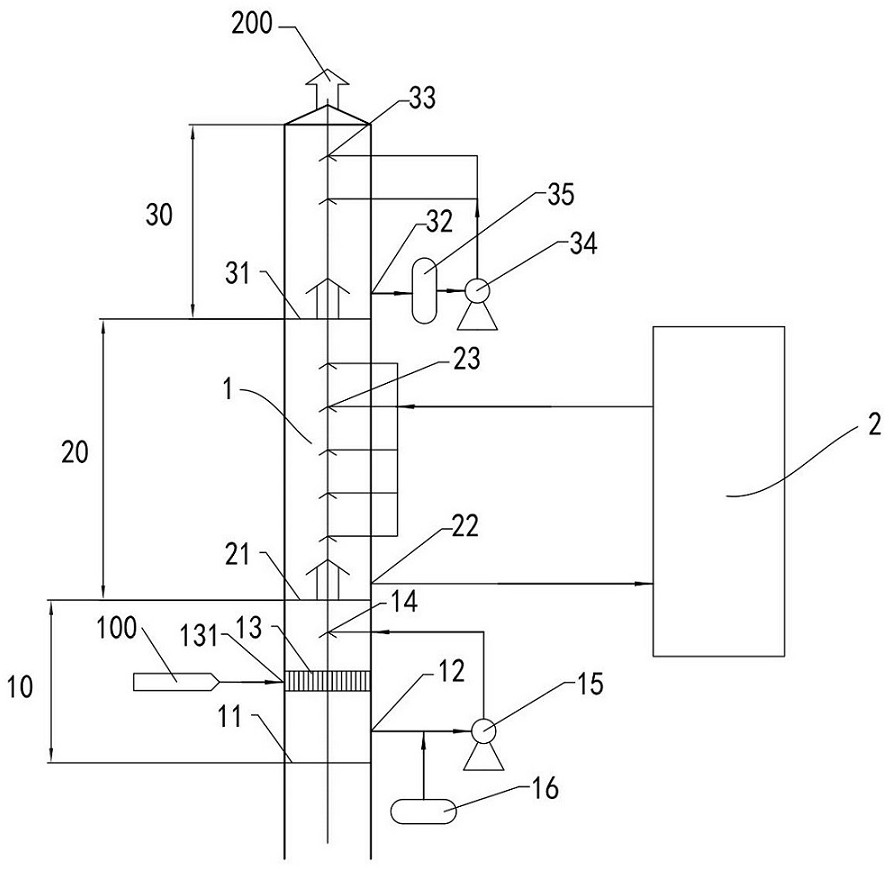

[0056] This embodiment provides a way to capture and recover CO 2 The chimney device, the chimney device is transformed from the existing chimney of the factory, such as figure 1As shown, an alkali washing section 10 and an absorption section 20 are set in the flue of the chimney 1, wherein the alkali washing section 10 desulfurizes and denitrates the flue gas by spraying lye. The absorption section 20 is set above the alkali washing section 10, and absorbs the CO in the flue gas after alkali washing by spraying lean liquid. 2 .

[0057] The alkali washing section 10 includes from bottom to top: a liquid collection tray 11, an alkali outlet 12, a gas distributor 13 and an alkali nozzle 14, wherein the gas distributor 13 has a flue gas inlet 131, and the flue gas 100 to be treated After entering the gas distributor 13 through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com