BOPP film surface multi-layer film coating method and device

A technology of multi-layer coating film and film covering device, which is applied to the surface coating liquid device, pretreatment surface, coating and other directions, which can solve the problems of film defects, flow traces, unevenness and other problems, and achieve uniform film coating , good lamination effect, better lamination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A multilayer coating method of a BOPP film surface, including the following steps:

[0035] S1. Wipe the plastic pipe with a BOPP film in advance, then adjust the paint layer, intermediate coating and the paint layer;

[0036] S2. Apply the primer layer coating to the plastic tube through the coating device 1, and then dry for 4 hours;

[0037] S3. Apply the intermediate coating coating of the debugging to the outside of the plastic tube through the coating device 1, and then dry for 4 hours;

[0038] S4. Apply a tested topcoat layer coating to the outside of the plastic tube through the coating device 1, and then dry for 4 hours.

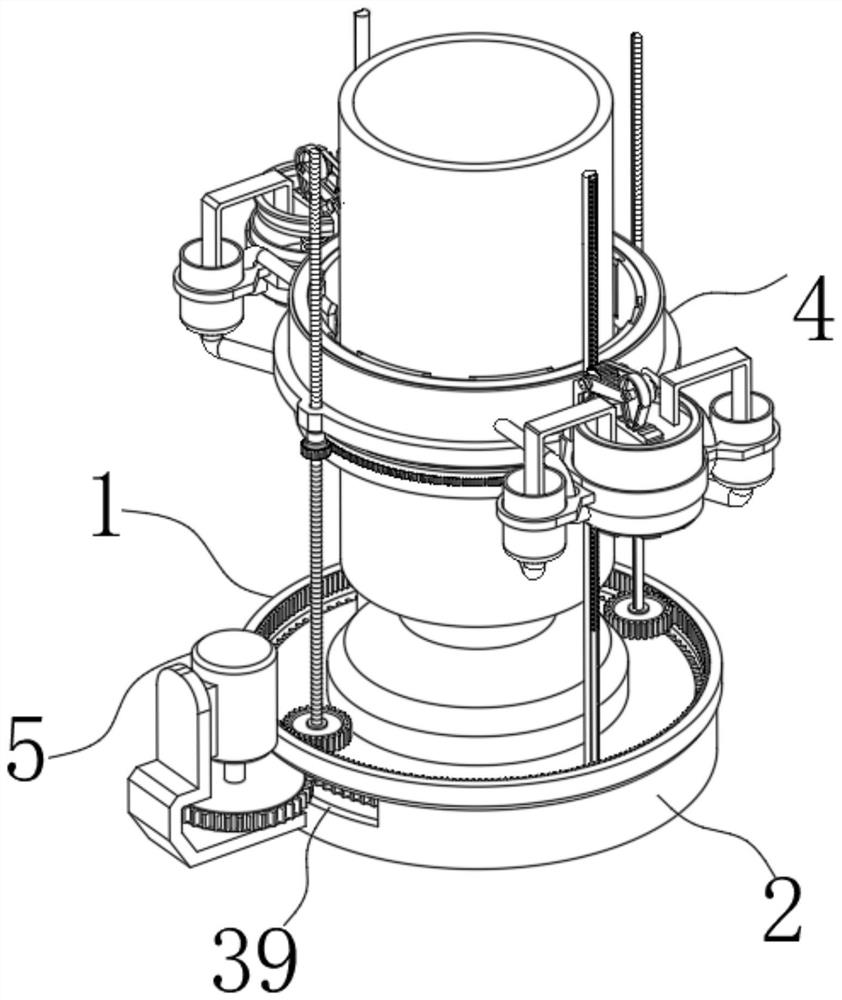

[0039] In this embodiment, please refer to figure 1 The coating apparatus 1 in the illustrated film includes a bottom table 2, and a rotating table 3 is rotated in the base 2, and the rotation table 3 is mounted with a photovation mechanism 4 for paint applications, and the drive member 5 is mounted outside the rotation table 3;

[0040] It shou...

Embodiment 2

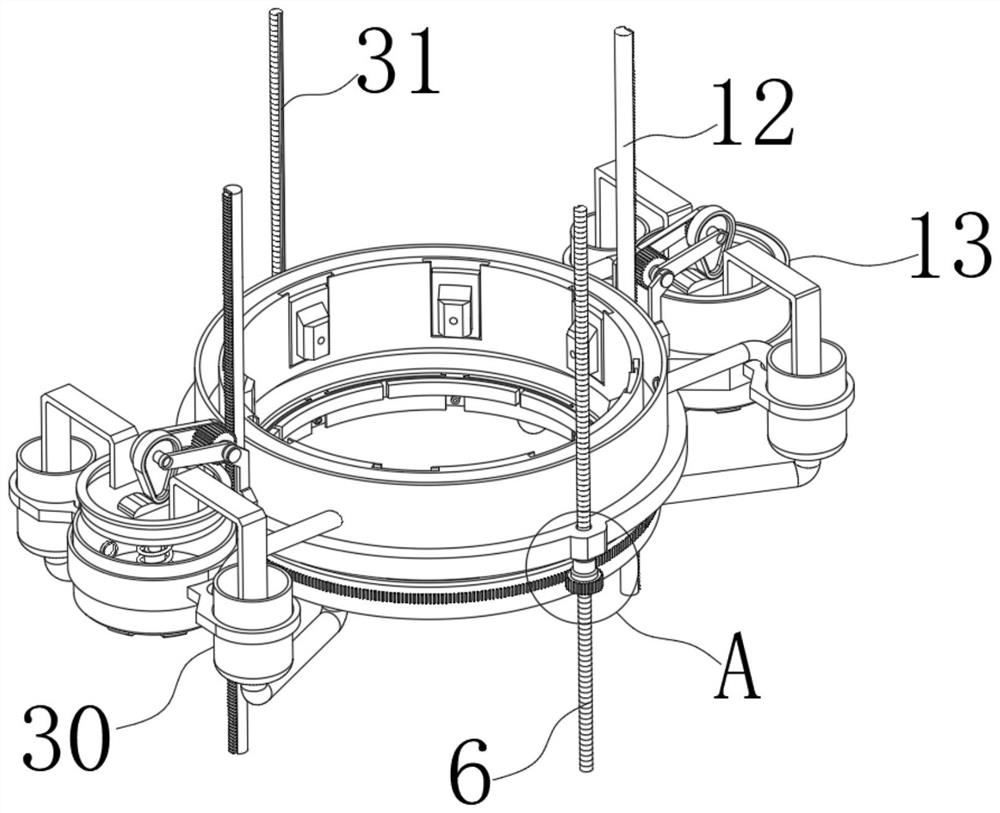

[0051] See Figure 5 - Figure 7 The present embodiment is further explained in the first embodiment, and the clamping assembly 14 in the illustrated map includes a spray frame 27 that rotates at the bottom of the moving ring 7, and the casing frame 27 is rotated at the bottom of the closure plate, a hlamp The mounting groove 28 is opened inside, and the mounting groove 28 is inserted with a brush plate that is fitted with the outer wall of the plastic tube, and the inner portion of the mounting groove 28 is fixed at the inner position of the mounting groove 29, the splay frame. The outer side of the 27 is fixed, and the wire rod 6 is opened, and the outer sheet of the outer casing steering gear 32 is fixed to the outer side of the steering gear 32, and the rotation column 33 is rotatably connected to the bottom of the moving ring 7. The outer side of the hula frame 27 is fixed to the transmission tooth ring 34 with the steering gear 32.

[0052] It should be noted that in this aspe...

Embodiment 3

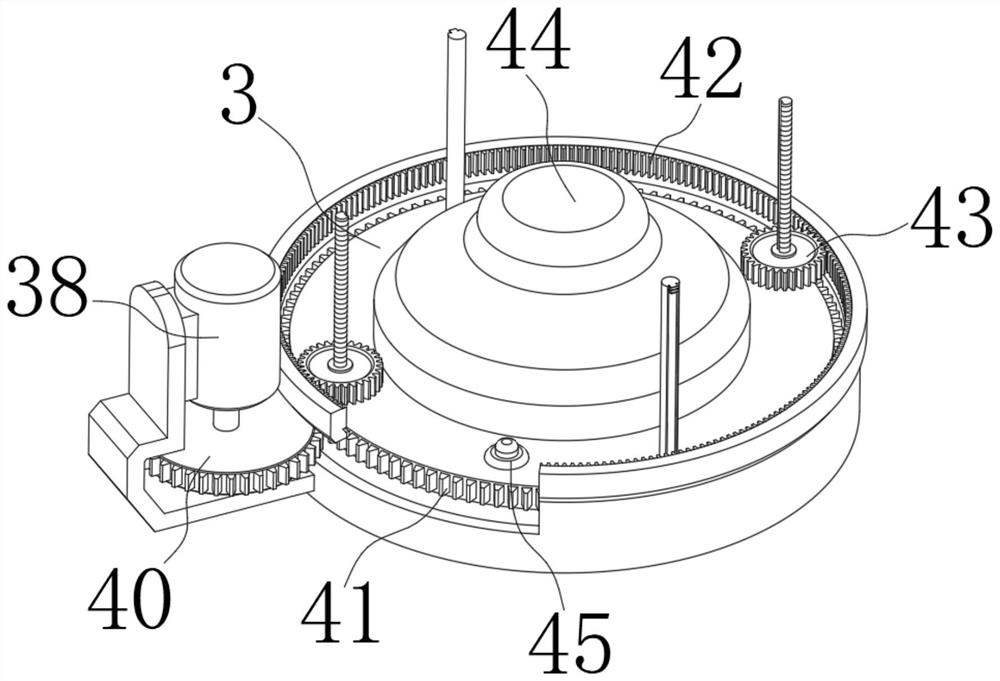

[0057] See figure 2 The present embodiment is further illustrated for other embodiments, and the coating apparatus 1 in the illustrated film includes a bottom table 2, and a turntable station 3 is rotated in the bottom 2, and the rotation table 3 is mounted with a smear body 4 for paint applications. The drive 5 is mounted outside the rotation table 3.

[0058] Among them, a connecting sleeve 44 is attached at the intermediate position of the rotation table 3, and one end of the rotation table 3 is fixed to the air nozzle 45 in communication with the connection sleeve 44.

[0059] It is worth noting that the connecting sleeve 44 in this scenario is a rubber sleeve, which can be expanded by blowing.

[0060] In this scheme, when the interaction of the connection sleeve 44 and the air supply nozzle 45 is mounted on the rotation table 3, the inner wall of the plastic conduit can be discharged to the inner wall of the plastic conduit by the connection sleeve 44, so that the plastic pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com