Online detection device for rheology of micro-injection molded polymer under ultrasonic energy field and online detection method

A detection device, micro-injection technology, applied in the direction of complex mathematical operations, etc., can solve the problem that it is difficult to accurately describe the viscosity characteristics of the melt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

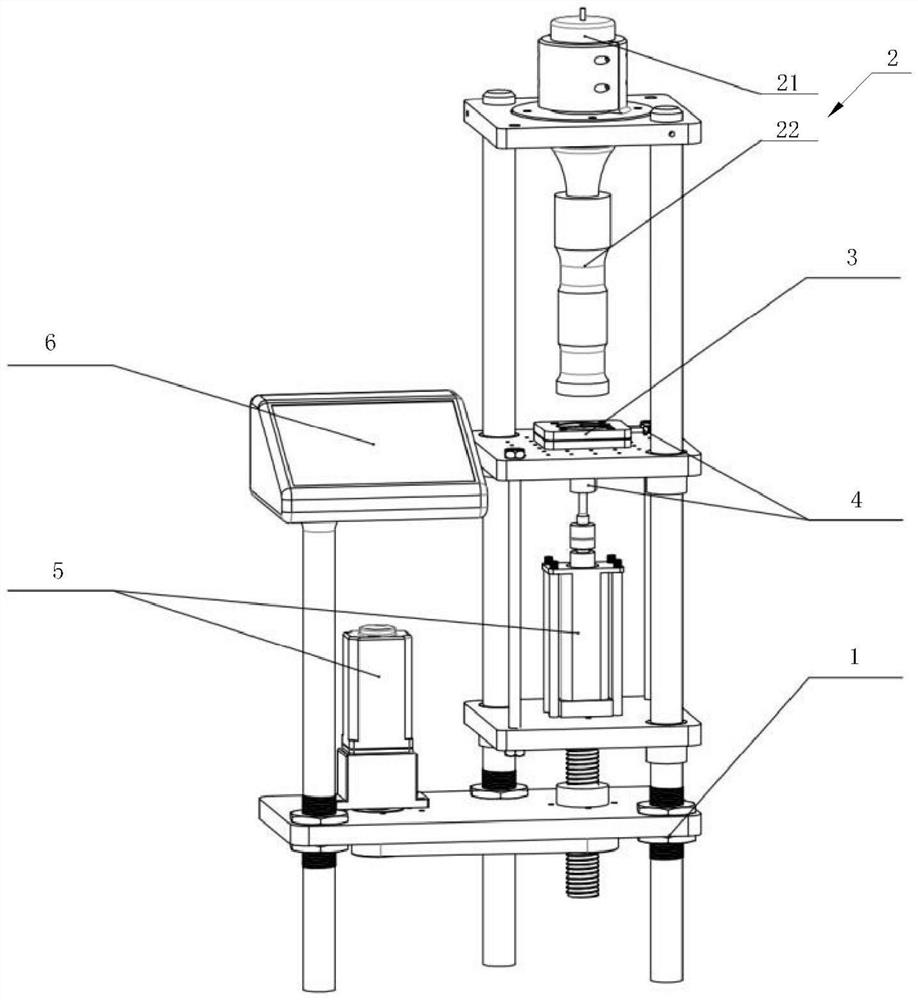

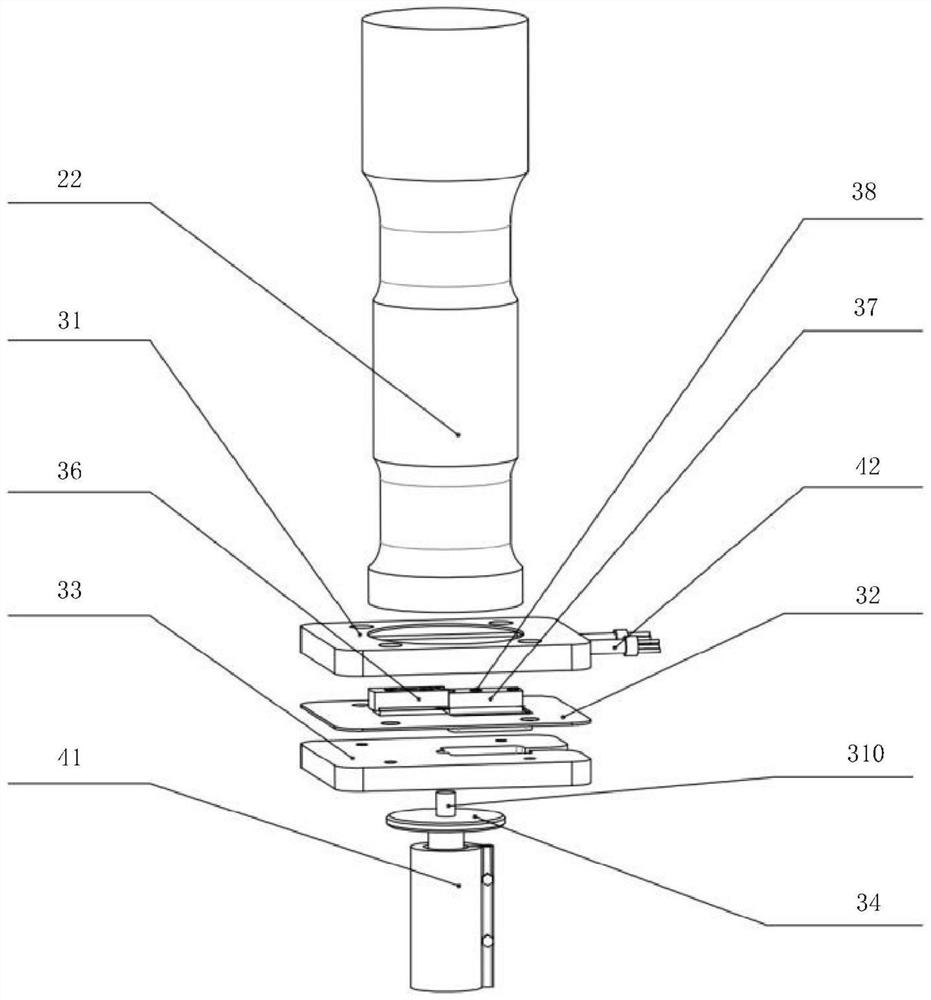

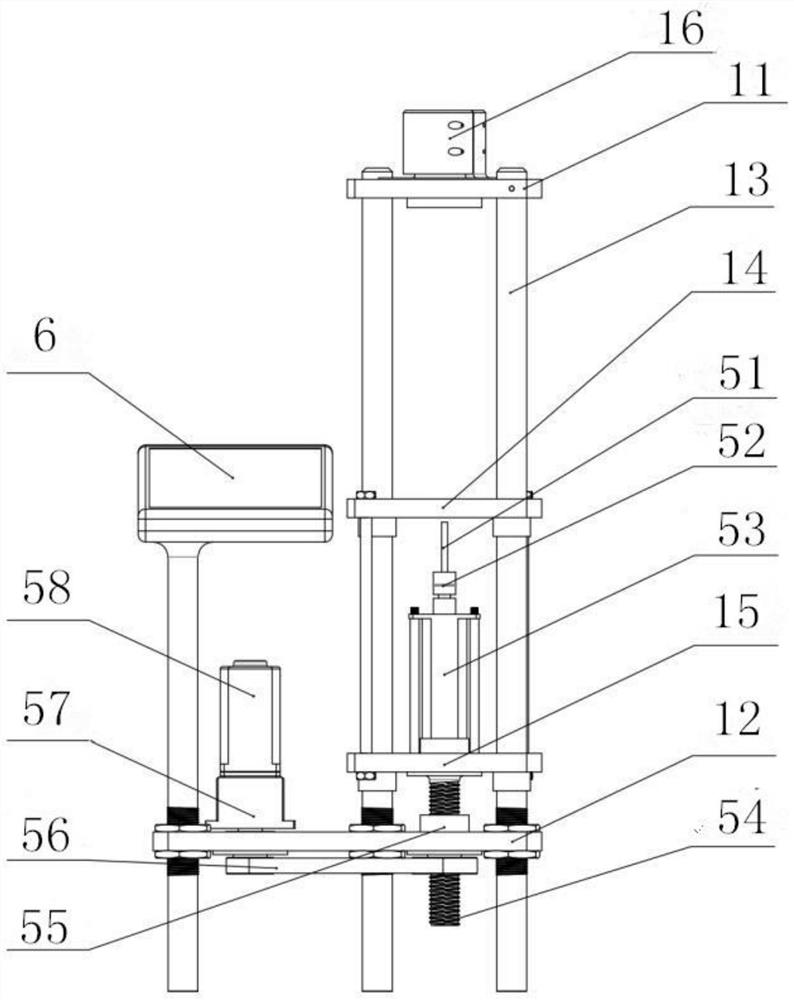

[0073] from Figure 1 to Figure 5 It can be seen that the micro-injection molding polymer rheological on-line detection device of the present invention includes a frame 1 and an ultrasonic vibration unit 2, a test mold 3, a heating unit 4 and a dynamic loading set on the frame 1. Unit 5, the ultrasonic vibration unit 2 is arranged just above the test mold 3, and is used to be responsible for generating and providing an ultrasonic energy field with a certain range of frequency and amplitude; the heating unit 4 is installed at the bottom of the test mold 3 to provide the plasticizing temperature; Power The loading unit 5 is installed under the test mold 3 for controlling the opening or closing of the test mold 3 and the injection of the polymer.

[0074] from figure 1 and image 3 It can be seen that the rack 1 in the present invention includes a fixed frame and a movable frame mounted on the fixed frame that can move up and down. The fixed frame includes a top plate 11 , a bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com