Method for manufacturing and installing segmented web of wind power blade

A technology for wind power blades and webs, which is applied in the manufacture and installation of wind power blade segmented webs. It can solve the problems of difficult transfer of large integrated perfusion blade webs, and achieve the effects of saving transfer space, wide application range, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

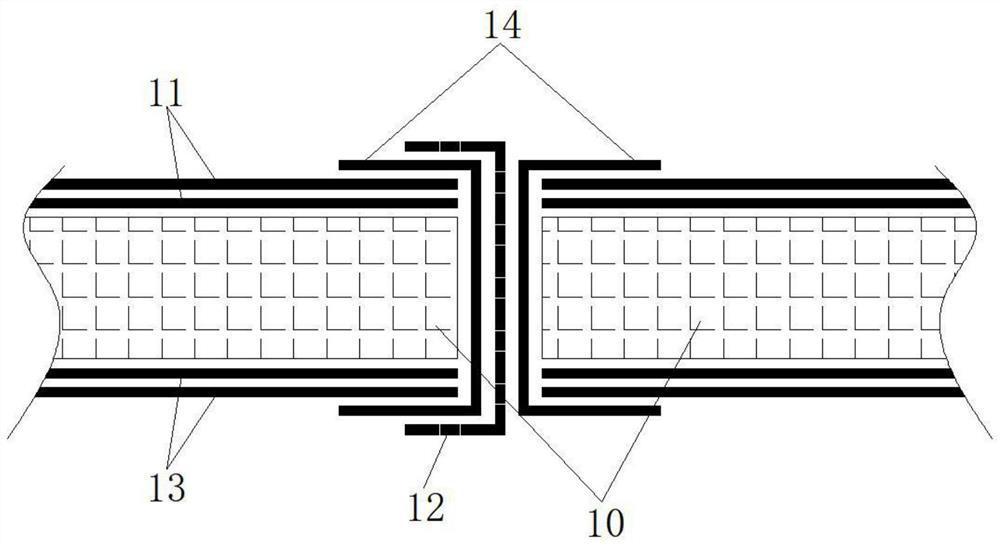

[0041] see Figure 1-3 , a segmented web of a wind power blade, comprising a web mold and a web, the web mold includes a core material 10, the upper surface of the core material 10 is wrapped with a release cloth 11, and the lower surface of the core material 10 is laid with an outer skin cloth 13, and the outer wall of the release cloth 11 and the outer skin cloth 13 is laid with an inner skin cloth 14, and a perforated film 12 is installed between two adjacent inner skin cloths 14;

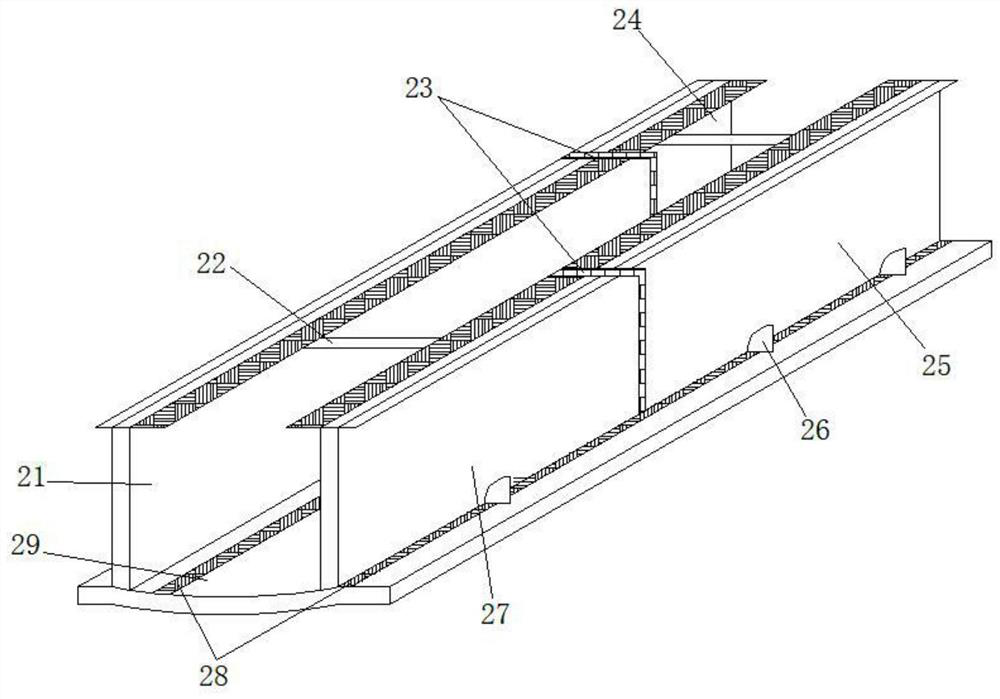

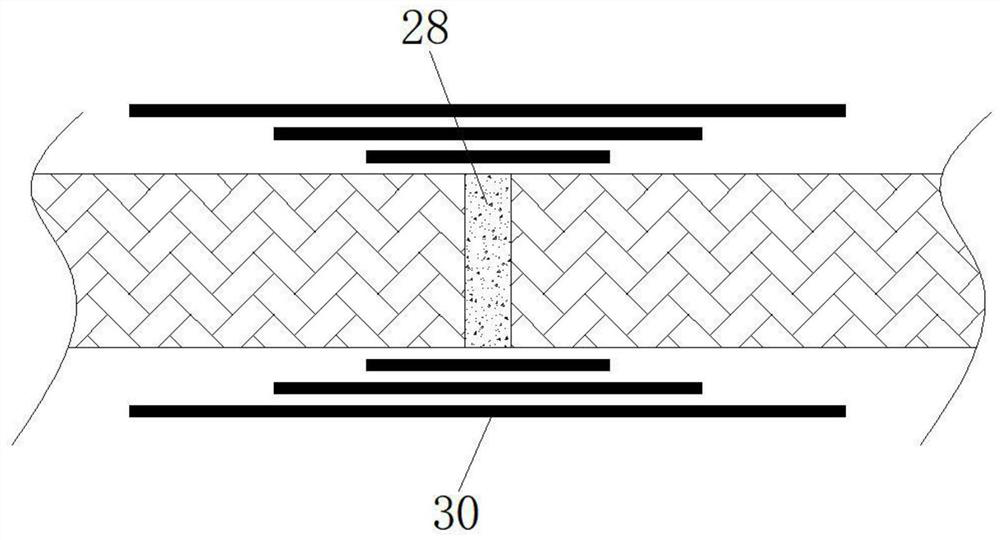

[0042] The web comprises a leading edge root plate 21 and a trailing edge root web 27, the rear end of the leading edge root plate 21 is equipped with a leading edge tip web 24, and the rear end of the trailing edge root web 27 is equipped with a trailing edge tip web plate 25, and the intersection of the leading edge root plate 21 and the leading edge tip web 24 and the intersection of the trailing edge root web 27 and the trailing edge tip web 25 are provided with web joints 23, and the leadin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com