Transfer trolley for turnover box of battery replacing station

A transfer vehicle and turnover box technology, which is applied to electric vehicles, trolleys, motor vehicles, etc., can solve the problems of increased environmental pollution control, performance degradation, and difficulty in maintenance and calculation by charging merchants, and achieves the effect of flexible rotation and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below with reference to accompanying drawing, the specific embodiment of the present invention and each system, each part, the interconnection relation between each device, the effect of each part and working principle are further explained:

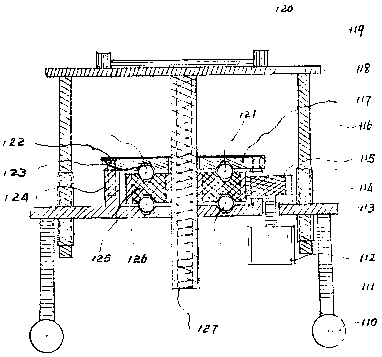

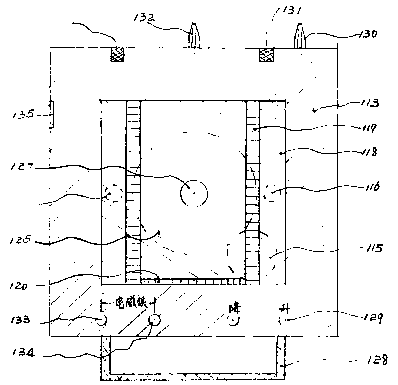

[0028] Such as figure 1 figure 2 As shown, the present invention is a turnover box transfer vehicle system for a power station, which includes a transfer vehicle table that can rotate freely, a set of lifting machinery, a set of stable lifting platform, a set of guide rail neat docking device and an anti- Close the door card password controller.

[0029] The transfer car table that can be rotated freely includes four legs (111) installed under the table top (113) and four direction-changing wheels (110) at the bottom of the legs, and its function is to change the transfer car conveniently. direction, the square table top (113) has a ball groove (123) for the lower bearing ball (126), this ball groove can also be the bottom groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com