Bolt entity grid modeling and loading method

A bolt and mesh technology, applied in the field of bolt solid mesh modeling and loading, can solve the problems of error-prone, time-consuming, tedious and repetitive operation process, and achieve the effect of standardizing the operation process and saving labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0065] In order to clearly and completely describe the technical solution of the present invention and its specific working process, in conjunction with the accompanying drawings, the specific implementation of the present invention is as follows:

[0066] In the present invention, unless otherwise clearly specified and limited, terms such as "installation", "connection", "connection" and "fixation" should be understood in a broad sense, for example, it can be a fixed connection or a detachable connection , or integrated; it may be mechanically connected or electrically connected; it may be directly connected or indirectly connected through an intermediary, and it may be the internal communication of two components or the interaction relationship between two components, unless otherwise specified limit. Those of ordinary skill in the art can understand the specific meanings of the above terms in the present invention according to specific situations.

[0067] In the present i...

Embodiment 1

[0070] A bolt solid mesh modeling and loading method, comprising the following steps:

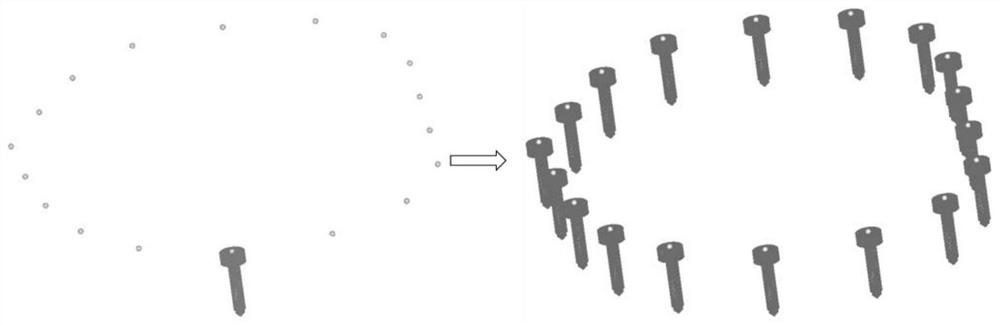

[0071] Such as Figure 1-3 As shown, step 1 is to establish the finite element model of the transmission housing assembly, the gear shaft and the bearing used on the transmission housing assembly in the Hypermesh software, and then use the TCL language to create all the gear shafts and bearings used on the transmission housing assembly. The finite element model of the bolt;

[0072] Step 2, create constraint points - rigid connection elements of some nodes of the transmission case, and apply constraints;

[0073] Step 3, apply TCL language to automatically distinguish bolt models and apply bolt pretightening force:

[0074] 1. Using TCL language to automatically create bolt preload loading points;

[0075] 2. Using TCL language to automatically apply bolt pretightening force;

[0076] 3. Using TCL language to automatically create the bolt pre-tightening surface;

[0077] 4. Apply TCL l...

Embodiment 2

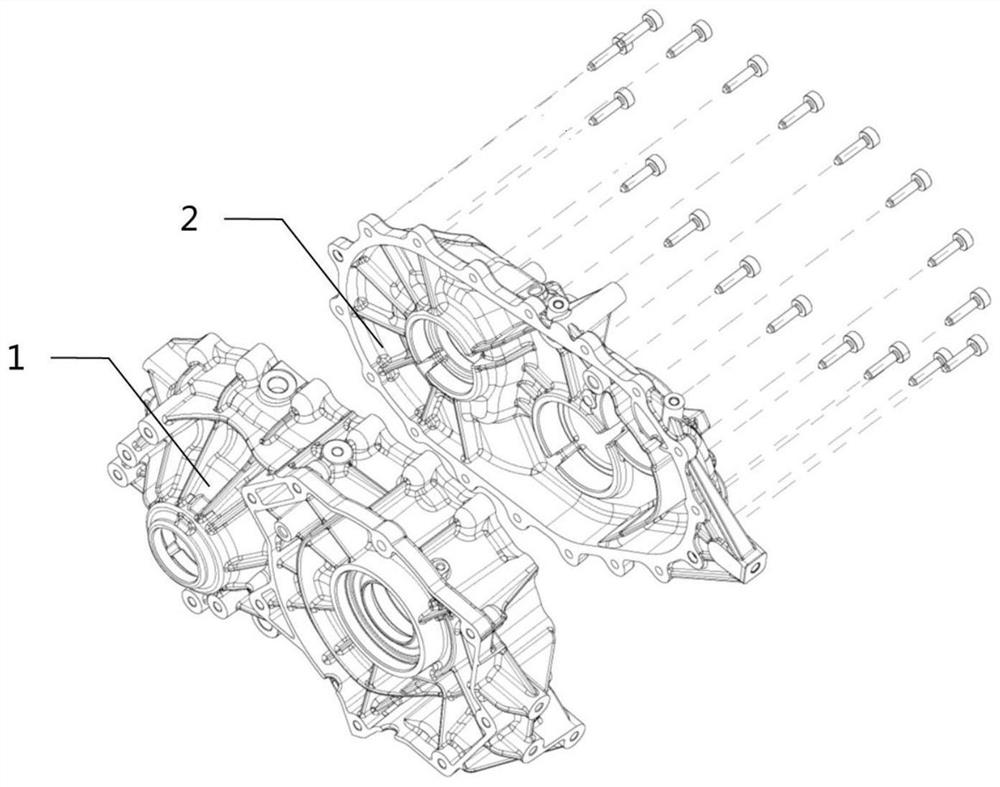

[0125] The first step, as attached figure 1 , to establish the assembly finite element model of the transmission case:

[0126] 1) Establish finite element models such as transmission front housing 1 and transmission rear housing 2 in Hypermesh software.

[0127] 2) Establish the finite element model of the transmission housing assembly bolt 3 in the Hypermesh software:

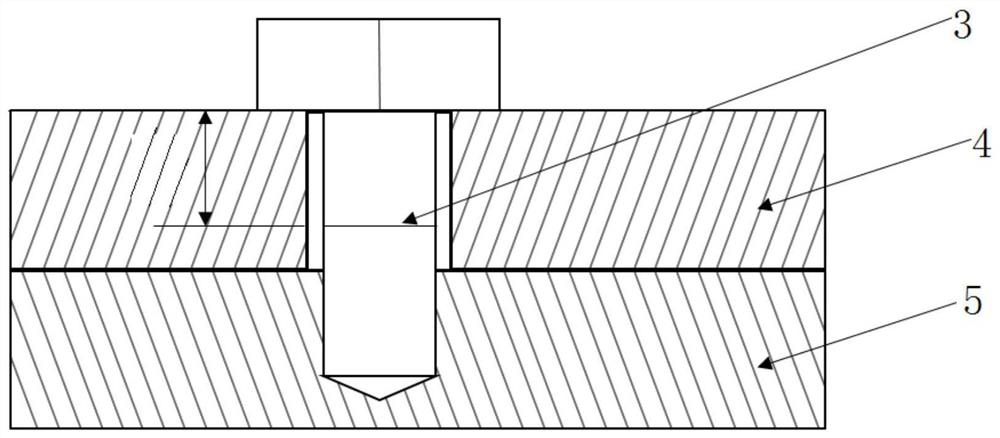

[0128] ① Group all bolts by diameter and screw length;

[0129] ② Taking a bolt with a diameter of 8mm as an example, take out the geometric model of any bolt, and use a plane perpendicular to its screw to cut the upper and lower parts of the closed body at the place where the thickness of the screw is smaller than the thickness of the connected part-4. The geometry of the upper and lower parts is divided by tetrahedral mesh, and the two parts share all the nodes of the cutting surface, and the screw part is the same as the mesh node of the bolt hole of the transmission case. The upper and lower parts are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com