Radiation disc structure and processing method of heat insulation ring on radiation disc

A processing method and technology of disk structure, which are applied to heating elements, electric heating devices, manufacturing tools, etc., can solve the problems of poor strength, poor replaceability, and easy breakage of thermal insulation rings, and achieve good thermal insulation performance, strength is not easy to deform, The effect of meeting assembly requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

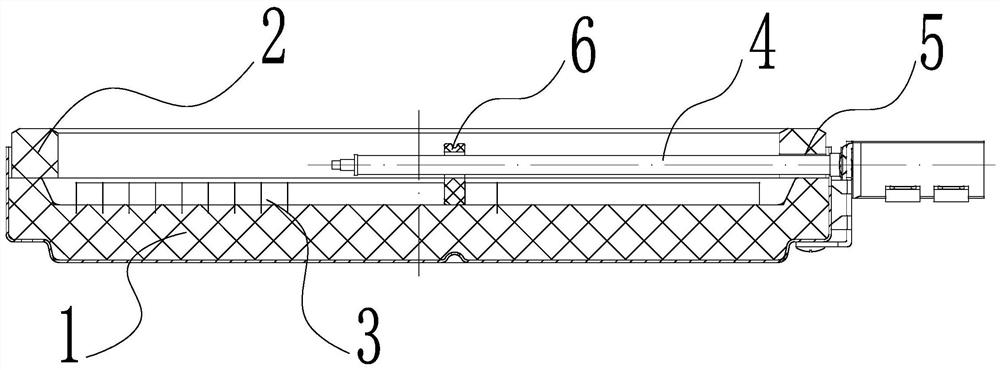

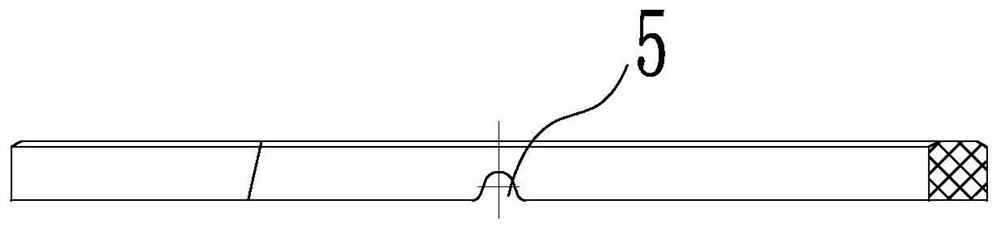

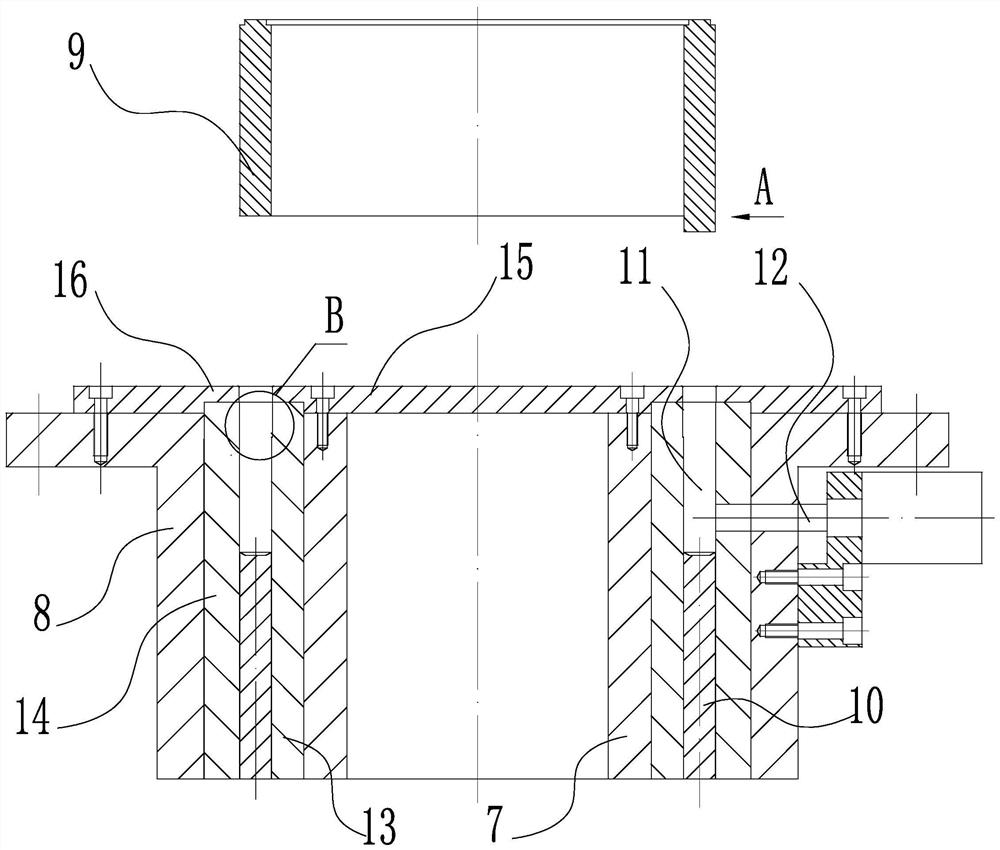

[0030] Such as figure 1 and figure 2 As shown, a radiant disk structure of the present invention includes a disc-shaped insulating base 1 and a heat insulating ring 2 docked at the port of the insulating base 1. The bottom of the insulating base 1 is tiled with a resistance wire 3, and above the resistance wire 3 The temperature limiter 4 is suspended horizontally, the port edge of the insulating base 1 extends upwards to the lower edge of the fixed end of the temperature limiter 4, and the lower port of the heat insulation ring 2 corresponding to the fixed end of the temperature limiter 4 has a notch groove 5. In the example, the cross-sectional shape of the notch groove 5 is V-shaped, and the notch groove 5 can also be other shapes such as U-shaped or semicircular. The temperature limiter 4 is clamped and fixed between the notch groove 5 and the port of the insulating base 1, and the temperature limiter The test end of 4 extends to the middle of the insulating base 1 and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com