Nodular cast iron pipe ceramic lining layer coating equipment and forming process

A nodular cast iron pipe and ceramic lining technology, which is applied to heat treatment equipment, coatings, manufacturing tools, etc., can solve the problems of difficult formation of high-density, high-strength and strong adhesion ceramic lining layers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

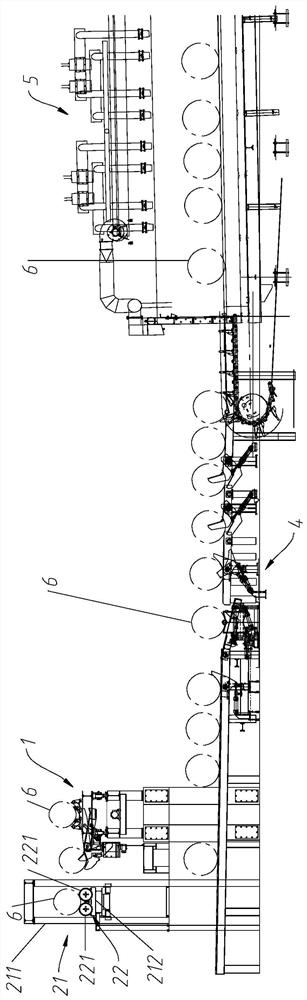

[0053] Such as Figure 1-4 As shown, the present invention proposes ductile iron pipe ceramic lining coating equipment, comprising:

[0054] Tube-making centrifuge and tube-extracting machine 1, the tube-extracting machine 1 is located on one side of the tube-making centrifuge, and the tube-extracting machine 1 is used to extract the formed ductile iron pipe from the pipe mold of the tube-making centrifuge, and also includes,

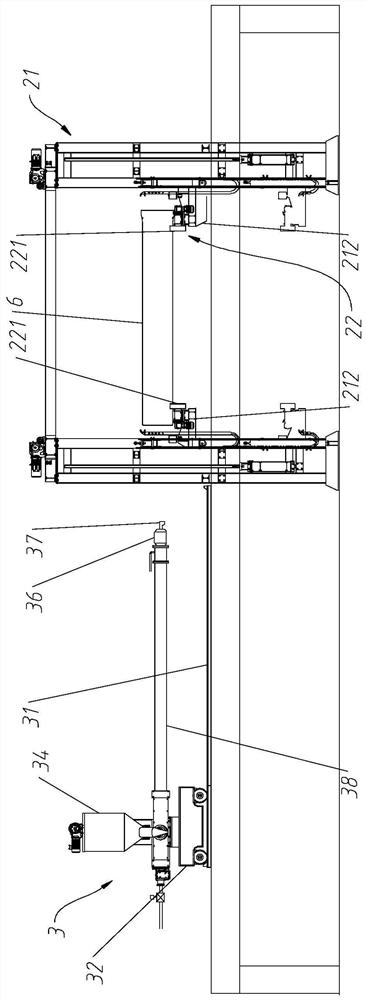

[0055] The lifting device 21 is located on one side of the extubation machine 1, and the lifting device 21 is rotated with a tugboat group 22, and the tugboat group 22 is used to support the ductile iron pipe,

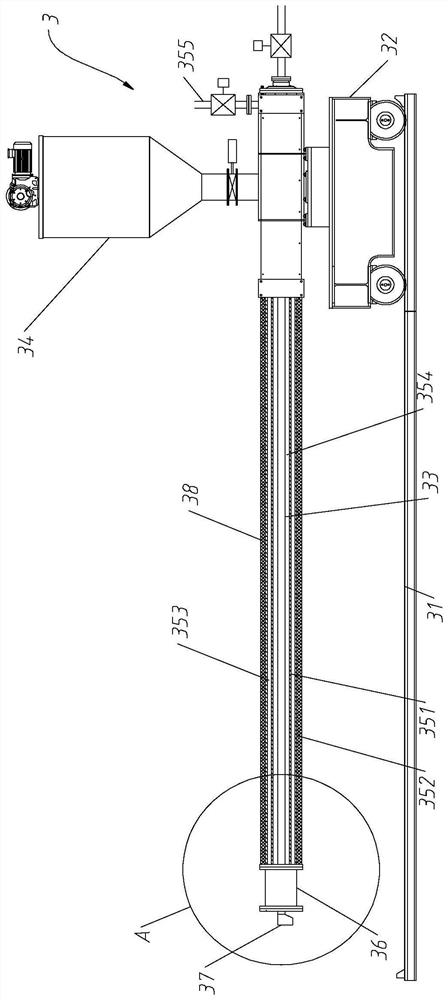

[0056] Lining mechanism 3 is arranged on one side of lifting device 21, and lining mechanism 3 is used for lining ceramic coating to the ductile iron pipe inner wall on the tugboat group 22,

[0057] The conveying mechanism 4 is arranged on the below of the tugboat group 22, and the nodular cast iron pipe is placed on the conveying mechanism 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com