Large high-temperature superconducting magnet system based on small refrigerating machine and temperature control method

A high-temperature superconducting and refrigerator technology, which is applied to superconducting magnets/coils, magnetic objects, electrical components, etc., can solve the problems of uneven conduction, increased labor, and long refrigeration cycles in large-scale high-temperature superconducting magnet systems, achieving The effect of reducing waiting time, avoiding manual control, and shortening the cooling cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

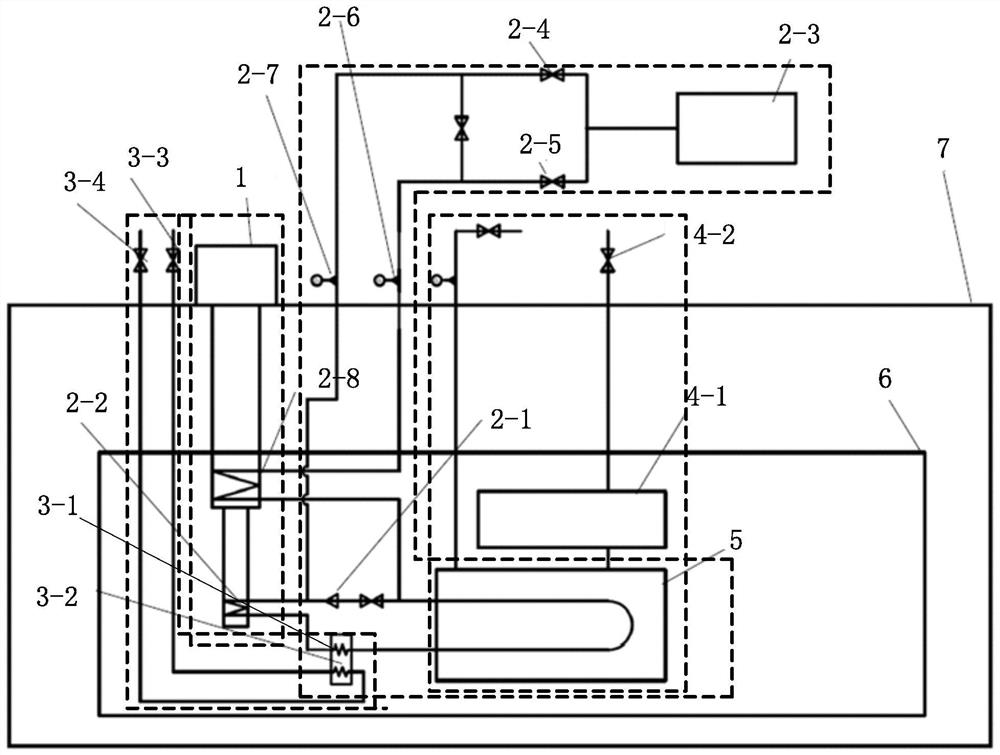

[0035] Design principle of the present invention

[0036] 1. The design of the helium refrigeration circuit, and the solution to the problem that manual control is required for cooling by secondary immersion, and automatic cooling cannot be realized: the minimum temperature of liquid nitrogen is 77K, which cannot meet the minimum cooling requirement of high-temperature superconducting magnets to 30K. The existing The technology uses two stages of immersion in different liquids to finally reach the cooling target of 30K, but in the process of replacing liquid nitrogen with liquid helium, manual control is required and automatic cooling cannot be achieved. The present invention uses the helium refrigeration circuit 2 to replace the "liquid helium" immersion in the secondary immersion method, thereby realizing the cooling from 77K to 30K: the principle is: the helium refrigeration circuit 2 exchanges heat through the secondary cold head of the helium circuit The GM refrigerator 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com