Bipolar plate assembly and fuel cell

A bipolar plate and component technology, applied in fuel cells, fuel cell parts, circuits, etc., can solve the problems of different gas flow rates, performance degradation, and no function of gas flow adjustment, so as to ensure uniformity, Improved performance, personalized tuning effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

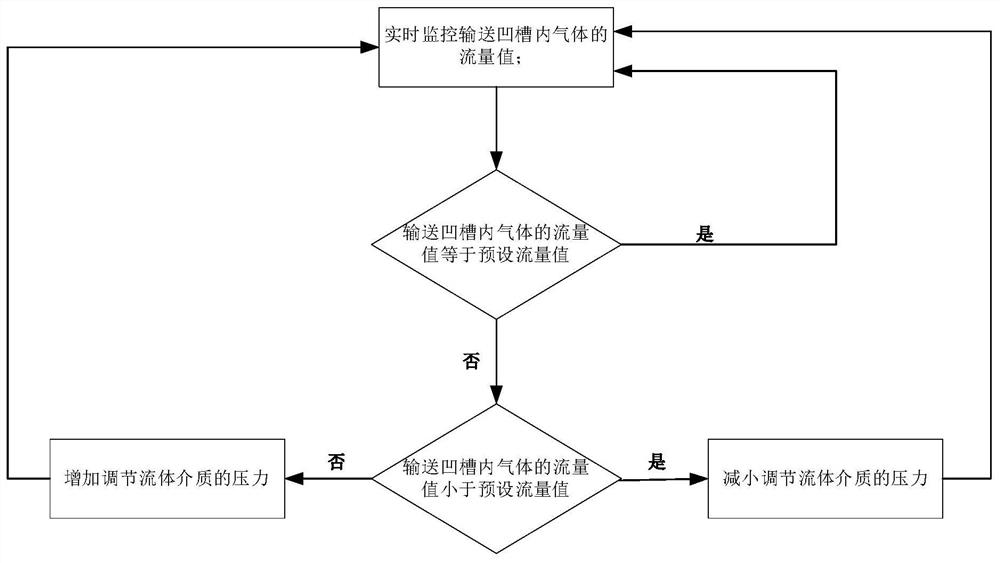

[0036] In the prior art, since the flow channels on both sides of the bipolar plate do not have the function of adjusting the gas flow, the gas flow of each flow channel is different, resulting in poor performance of the fuel cell.

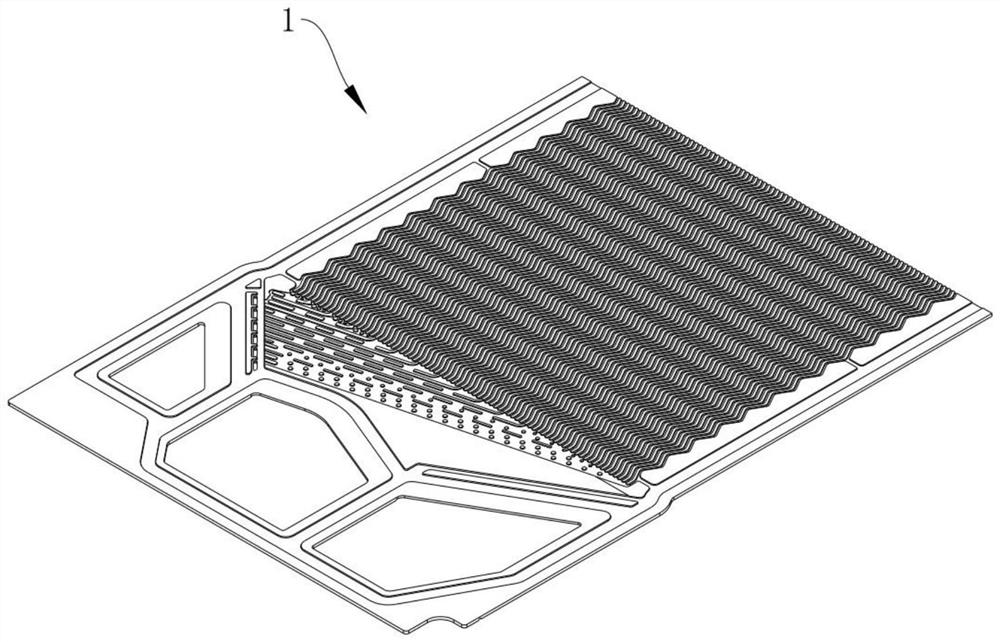

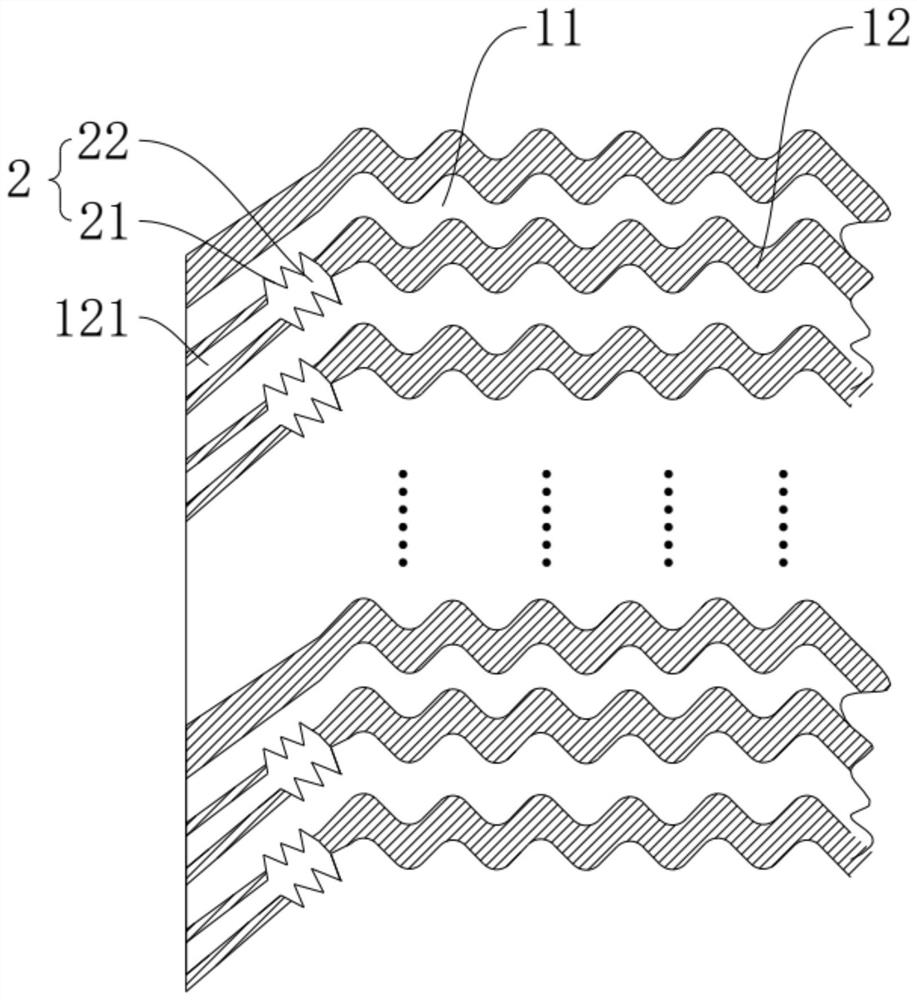

[0037] To solve the above problems, such as figure 1 and figure 2 As shown, this embodiment provides a bipolar plate assembly. The bipolar plate assembly includes a bipolar plate and an adjustment member 2. The bipolar plate includes a bipolar plate main body 1 and a plurality of flow channel ridges arranged on the bipolar plate main body 1. 12. A delivery groove 11 is formed between any two adjacent flow channel ridges 12, and the delivery groove 11 is used to deliver gas; the regulator 2 is used to adjust the fluid flow rate of the delivery groove 11. The fluid in this embodiment is a reactive gas.

[0038] Specifically, when the bipolar plate assembly is in use, the bipolar plate assembly needs to be used with a membrane electrode. The membr...

Embodiment 2

[0054] This embodiment also provides a fuel cell, including the above-mentioned bipolar plate assembly. The fuel cell also includes a membrane electrode, the bipolar plate assembly includes a bipolar plate main body 1 , and the membrane electrode covers the bipolar plate main body 1 . Due to the inclusion of the aforementioned bipolar plate assembly, it has the advantages of any one of the first embodiment, and realizes the adjustment of the gas flow in the gas channel, thereby ensuring the uniformity of the gas flow in multiple gas channels, so that the gas is fully reaction to improve the performance of the fuel cell.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com