Production line auxiliary box turnover mechanism for emerging energy automobile casting parts

A technology for castings and production lines is applied in the field of auxiliary turning mechanism for the production line of new energy automobile castings, which can solve the problems of affecting the production efficiency of castings, inconvenient operation, and high labor intensity, and achieves low labor intensity and high labor intensity for turning the box. The box is easy to operate, and the effect of turning the box is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

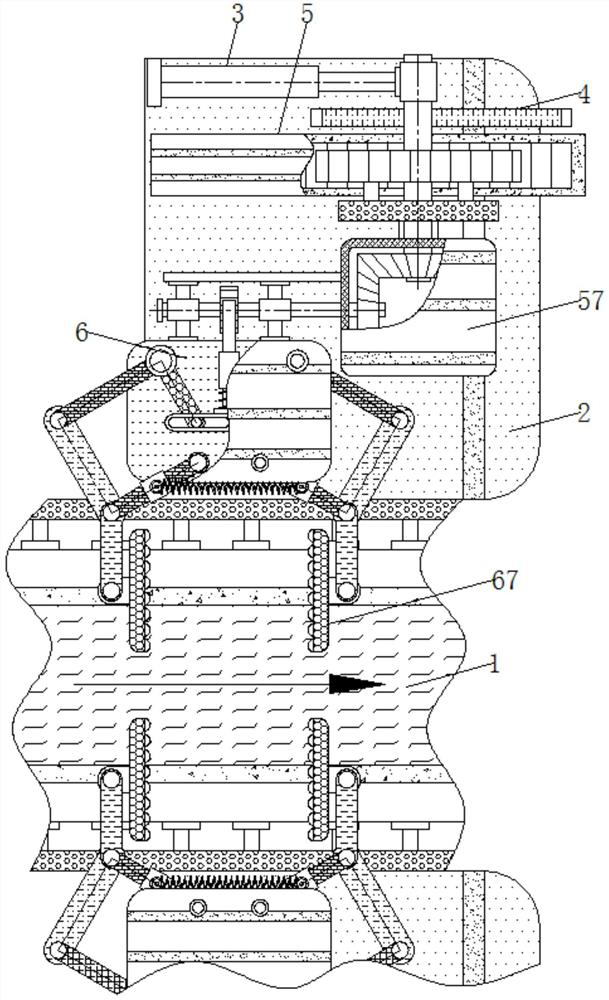

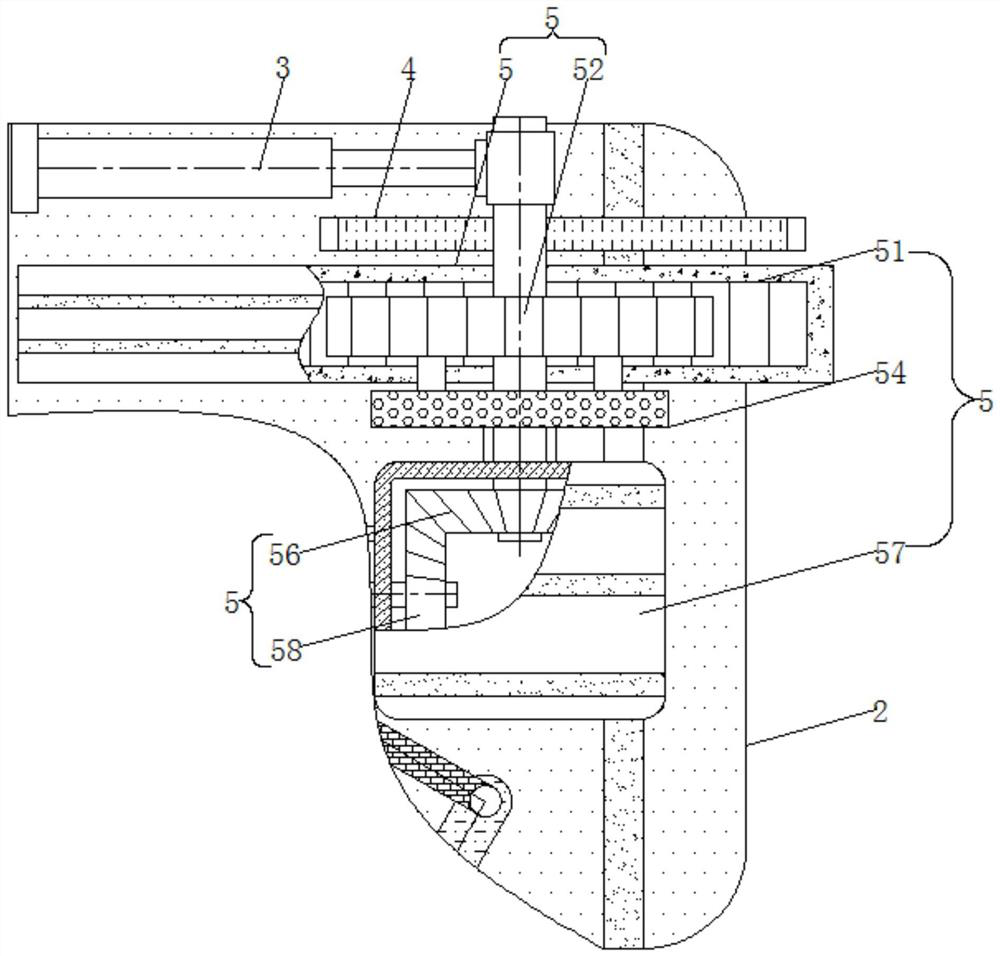

[0028] see Figure 1-4 , an auxiliary box-turning mechanism for a production line of emerging energy automobile castings, including a conveying device 1 for conveying casting boxes. The side surface of the conveying device 1 is provided with support plates 2. There are two sets of support plates 2, which are symmetrically distributed. On both sides of the conveying equipment 1, the surface of the support plate 2 is provided with a hydraulic rod 3, and the end of the hydraulic rod 3 away from the support plate 2 is connected to the drive gear 52 to drive the drive gear 52 to move. The surface of the support plate 2 is provided with a slide rail 4. It is used to drive the movement of the gear 52, including the turning box assembly 5.

[0029] The inside of the turning box assembly 5 is provided with a rack 51, the rack 51 is distributed parallel to the slide rail 4, meshes with the driving gear 52, and is used for the rotation of the driving gear 52, and the surface of the rack ...

Embodiment 2

[0032] see Figure 1-4 , an auxiliary box-turning mechanism for a production line of emerging energy automobile castings, including a conveying device 1 for conveying casting boxes. The side surface of the conveying device 1 is provided with support plates 2. There are two sets of support plates 2, which are symmetrically distributed. On both sides of the conveying equipment 1, the surface of the support plate 2 is provided with a hydraulic rod 3, and the end of the hydraulic rod 3 away from the support plate 2 is connected to the drive gear 52 to drive the drive gear 52 to move. The surface of the support plate 2 is provided with a slide rail 4, used to drive the movement of the gear 52.

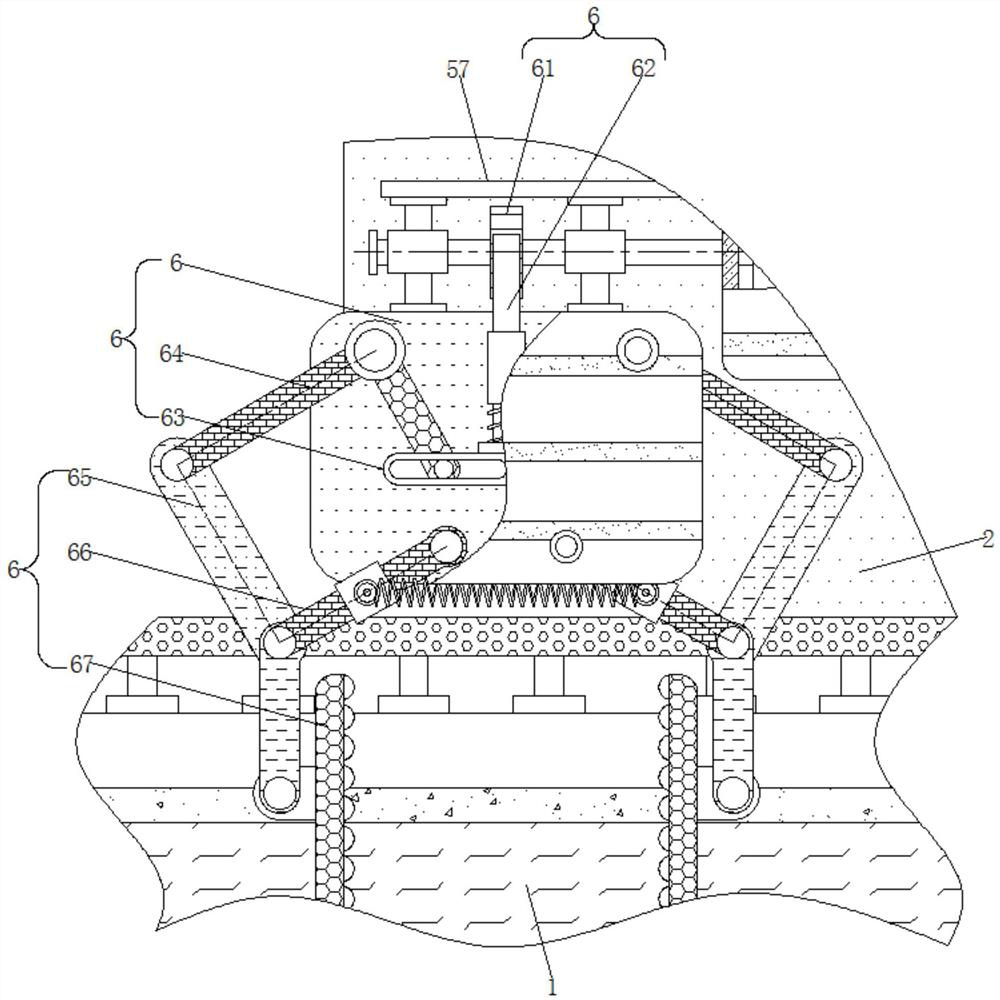

[0033] It includes a turning box assembly 5, which is used to drive the fastening mechanism 6 to rotate. The surface of the support member 57 is provided with a fastening mechanism 6. The interior of the fastening mechanism 6 is designed with a bottom plate, which is fixedly connected with ...

Embodiment 3

[0037] see Figure 1-4 , an auxiliary box-turning mechanism for a production line of emerging energy automobile castings, including a conveying device 1 for conveying casting boxes. The side surface of the conveying device 1 is provided with support plates 2. There are two sets of support plates 2, which are symmetrically distributed. On both sides of the conveying equipment 1, the surface of the support plate 2 is provided with a hydraulic rod 3, and the end of the hydraulic rod 3 away from the support plate 2 is connected to the drive gear 52 to drive the drive gear 52 to move. The surface of the support plate 2 is provided with a slide rail 4. It is used to drive the movement of the gear 52, including the turning box assembly 5.

[0038] The inside of the turning box assembly 5 is provided with a rack 51, the rack 51 is distributed parallel to the slide rail 4, meshes with the driving gear 52, and is used for the rotation of the driving gear 52, and the surface of the rack 51...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com