Wooden handle forming device special for farm tools

A molding device and wooden handle technology, applied in the direction of molding/shaping machines, special molding/shaping machines, manufacturing tools, etc., can solve the problems of high labor intensity, low processing efficiency, and difficulty in guaranteeing, so as to reduce workmanship intensity and improve Work efficiency, impact reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

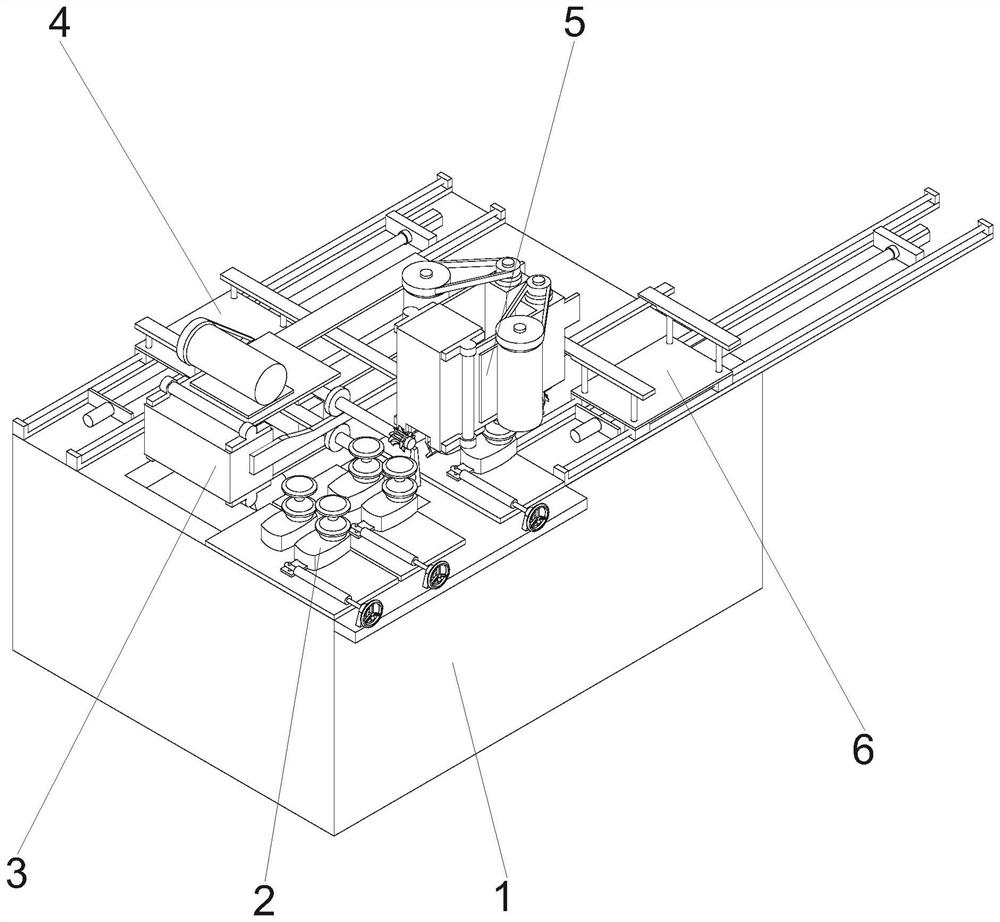

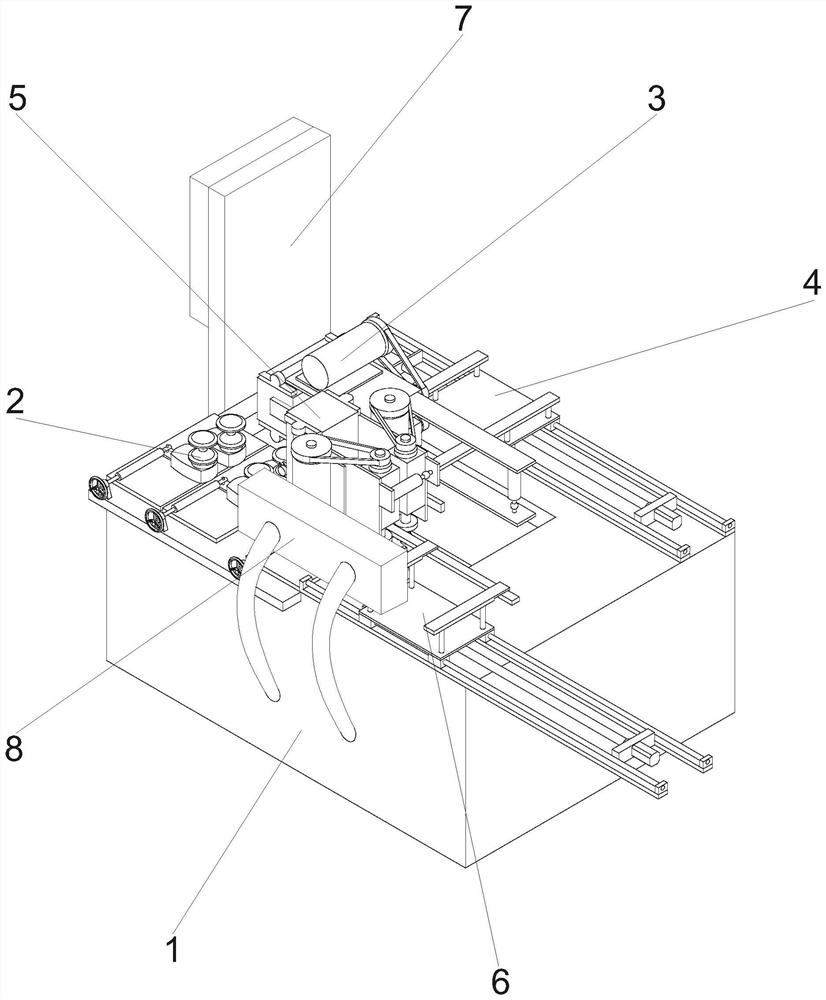

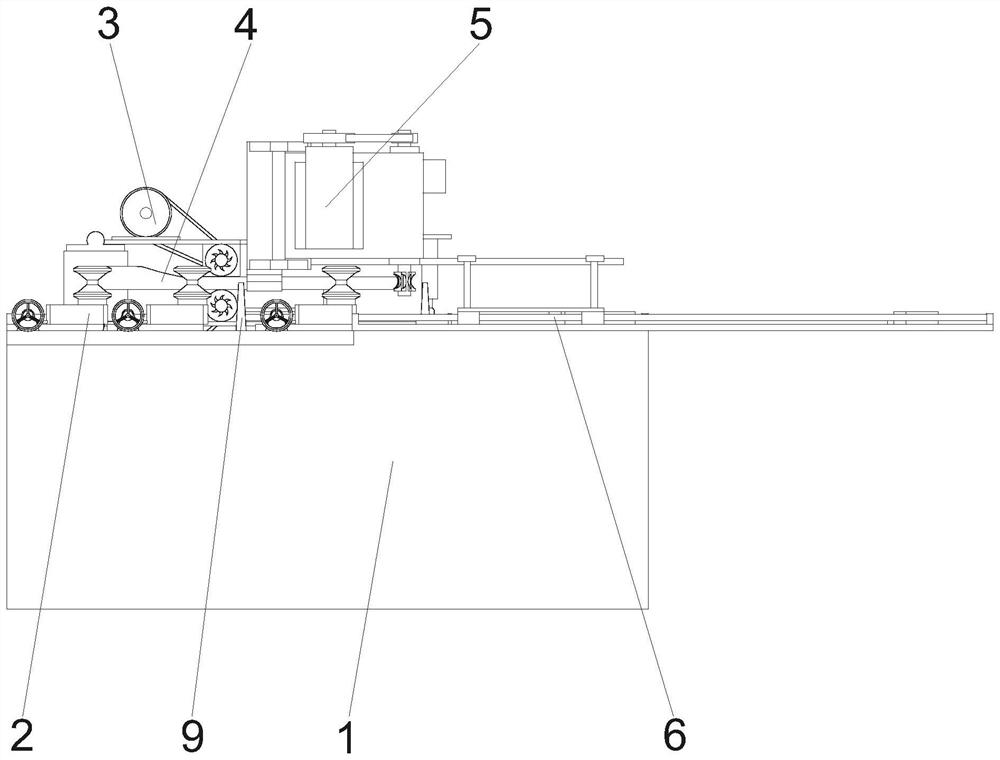

[0063] Please refer to Figure 1 to Figure 11 , a special wooden handle molding device for agricultural tools, including a machine platform 1, a feeding assembly 2, a forming mechanism and a shape control mechanism, the said machine platform 1 is provided with the said feeding assembly 2, and said machine platform 1 is also provided with a The forming mechanism, the forming mechanism is connected with the shape control mechanism;

[0064] The forming mechanism includes left and right forming components 5 and upper and lower forming components 3;

[0065] The shape control mechanism includes left and right shape control components 6 and up and down shape control components 4;

[0066] One side of the machine table 1 is provided with the left and right molding assemblies 5, the other side of the machine table 1 is provided with the upper and lower molding assemblies 3, and the left and right shape control assemblies 6 are connected to the left and right molding assemblies 5. c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com