Rail transit vehicle end wall

A technology for rail transit vehicles and end walls, which is applied to railway car bodies, parts of railway car bodies, transportation and packaging, etc. It can solve problems such as heavy weight of end walls, lack of fire protection, and easy deformation, so as to reduce mold costs, Prevent excessive opening and closing, and the effect of consistent gaps

Active Publication Date: 2022-01-11

ZHUZHOU TIMES NEW MATERIALS TECH

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

FRP sandwich generally uses glass fiber as the skin, with PET core material in the middle, and adopts vacuum infusion molding method. It is characterized by relatively simple molding process and strong modeling ability, but relatively poor dimensional stability, low rigidity, and easy deformation. , the weight is relatively large, and the fire protection has not met the needs of the current vehicles

The process of carbon fiber sandwich is the same as that of FRP sandwich, and it has the characteristics of high rigidity and not easy to deform, but its cost is high and it is not suitable for mass production

The aluminum honeycomb end wall has good rigidity, sound insulation and noise reduction performance, but due to the material characteristics, the aluminum honeycomb panel is suitable for making components with simple shapes and no complex curved surface shapes, and a large number of profiles are required in the production process And aluminum frame, heavy weight, does not meet the requirements of lightweight

The end walls of the above materials have the disadvantages of heavy weight, high cost, and insufficient safety performance under the same structural strength.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0067] Table 1 Example 1 plate mechanical properties

[0068]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

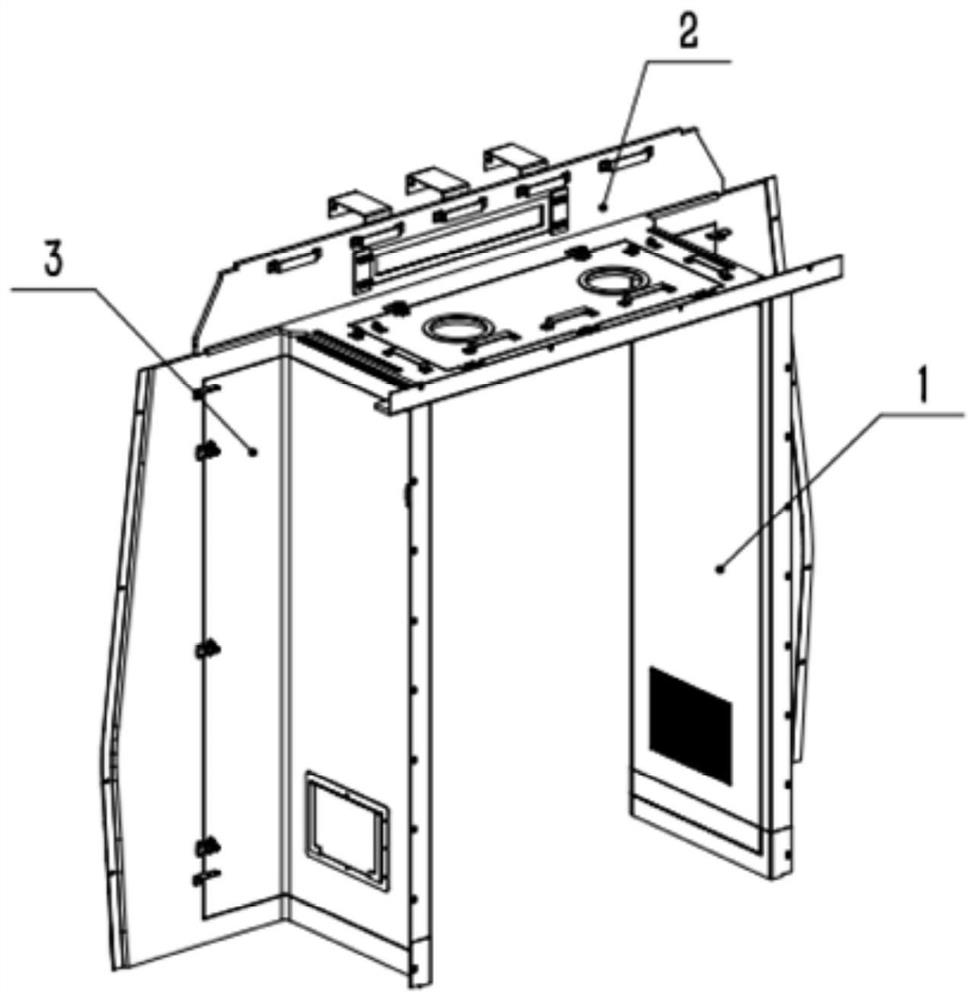

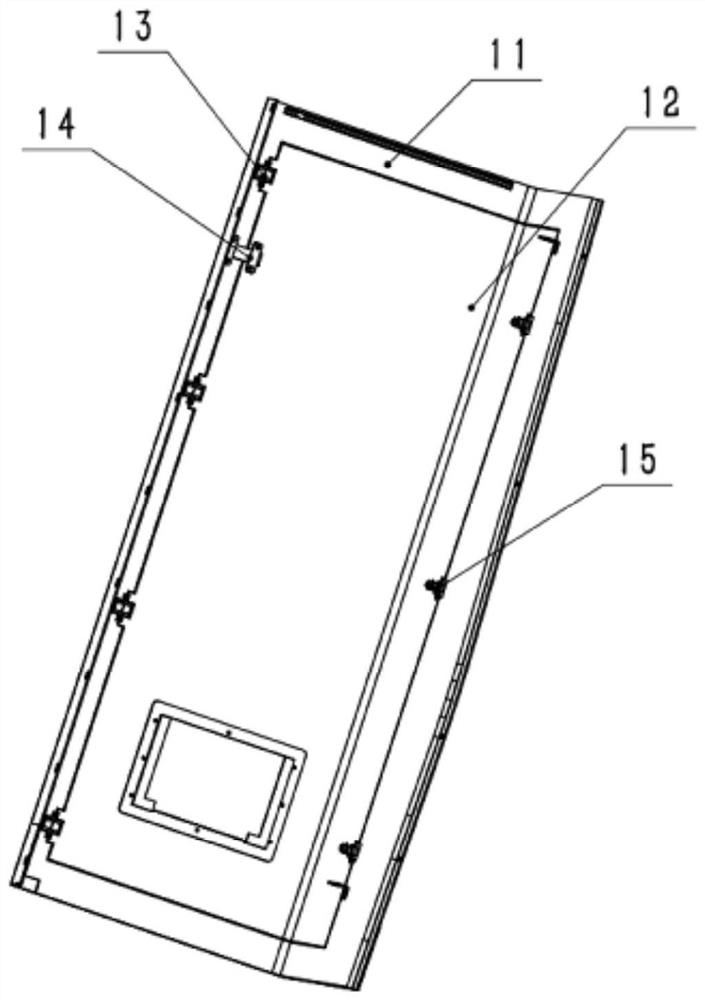

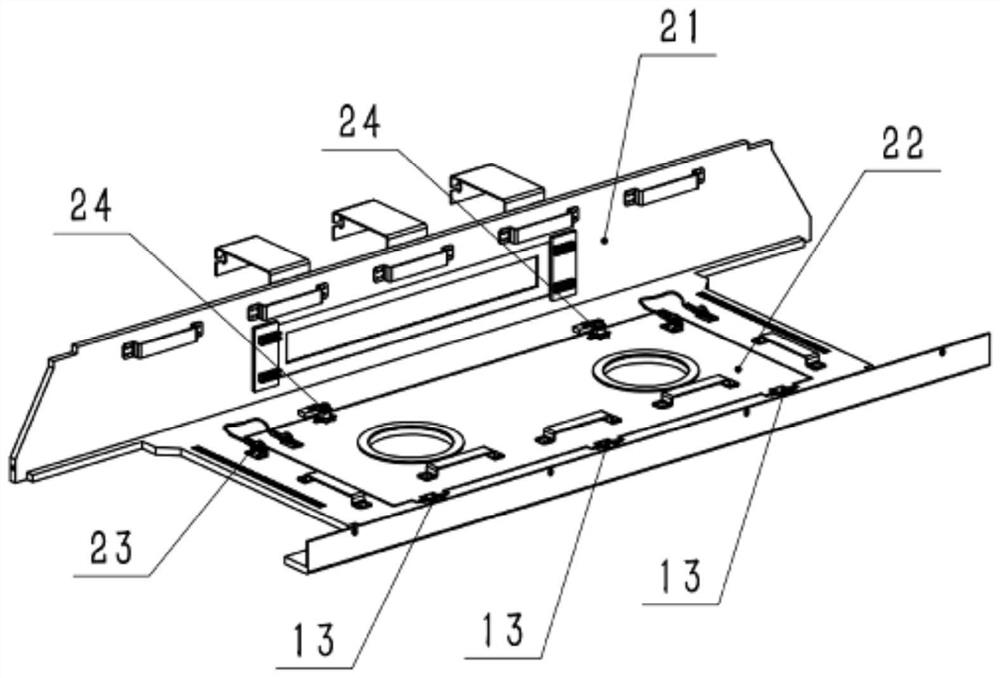

The invention provides a rail transit vehicle end wall which comprises a three-wall body formed by a left end wall body, an upper end wall body and a right end wall body which are integrally formed, at least one of the left end wall body, the right end wall body and the upper end wall body is provided with an access door in a separated mode in the three-wall body in a carving mode, and the access door is movably connected with a door frame separated from the three-wall body; the access door is movably connected with the door frame through hidden hinges, the hidden hinges are locked on embedded parts embedded in the access door and the door frame through screws, and the embedded parts are placed in prefabricated holes in the three-wall body. The rail transit vehicle end wall has the advantages of being high in strength, fireproof, environmentally friendly, capable of insulating sound and heat, attractive and the like, the weight and cost of the end wall can be effectively reduced, large electrical components can be more easily and conveniently overhauled, the number of molds can be reduced, and the mold cost can be reduced.

Description

technical field [0001] The invention belongs to the design of a rail transit vehicle, in particular to an end wall of a rail transit vehicle. Background technique [0002] With the rapid development of domestic and foreign rail transit fields, the lightweight of rail transit has received more and more attention. The light weight of rail transit has particularly important practical significance for vehicle weight reduction, speed increase, noise reduction, energy consumption reduction, and ride comfort improvement. In this context, under the premise of ensuring the overall strength of the vehicle, vehicle interior components become the key area of vehicle lightweight. The end walls used in rail transit vehicles not only require the product to be beautiful, but also have higher and higher requirements for product reliability, light weight, and convenient maintenance. The end wall is a relatively complicated part in the interior design. It is composed of the left end wall, ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B61D17/06B61D17/00B32B5/18B32B5/02B32B33/00

CPCB61D17/06B61D17/00B32B5/18B32B5/02B32B33/00B32B2266/0285Y02T30/00

Inventor 周旭日王梅甫袁利康林立钿周洲吴宏伟

Owner ZHUZHOU TIMES NEW MATERIALS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com