Constant tension control system of mask machine based on variable frequency transmission

A technology of control system and frequency conversion transmission, which is applied in the directions of coiling strips, thin material handling, transportation and packaging, etc. It can solve the problems of difficult maintenance, low precision of tension control, poor real-time performance, etc., and achieve slow adjustment speed and high tension Control precision and solve the effect of low tension control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

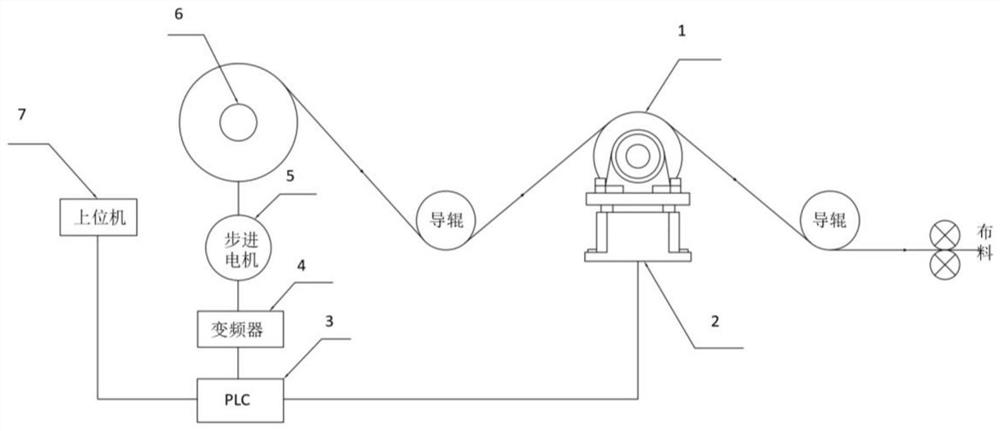

[0021] Please refer to figure 1 , a mask machine constant tension control system based on frequency conversion drive, upper computer 7 and constant tension control components;

[0022] Described constant tension control assembly comprises tension sensor 2, PLC3, frequency converter 4, stepper motor 5 and unwinding shaft 6;

[0023] The tension sensor 2 and the frequency converter 4 are electrically connected to the PLC3 respectively;

[0024] The tension sensor 2 obtains the actual tension value generated by the transmission cloth of the mask machine in the production process, and transmits it to the host computer 7 through PLC3;

[0025] After the host computer 7 processes the received actual tension value and the set tension value, it generates correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com