A unidirectional circular wire feeding system for electrolytic wire cutting

An electrolytic wire and ring-shaped technology, which is applied in the direction of electric processing equipment, electrochemical processing equipment, manufacturing tools, etc., can solve the problems of low service life, large deformation of the tensioning wheel, and low durability of the ring wire, so as to improve the durability , the effect of small deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

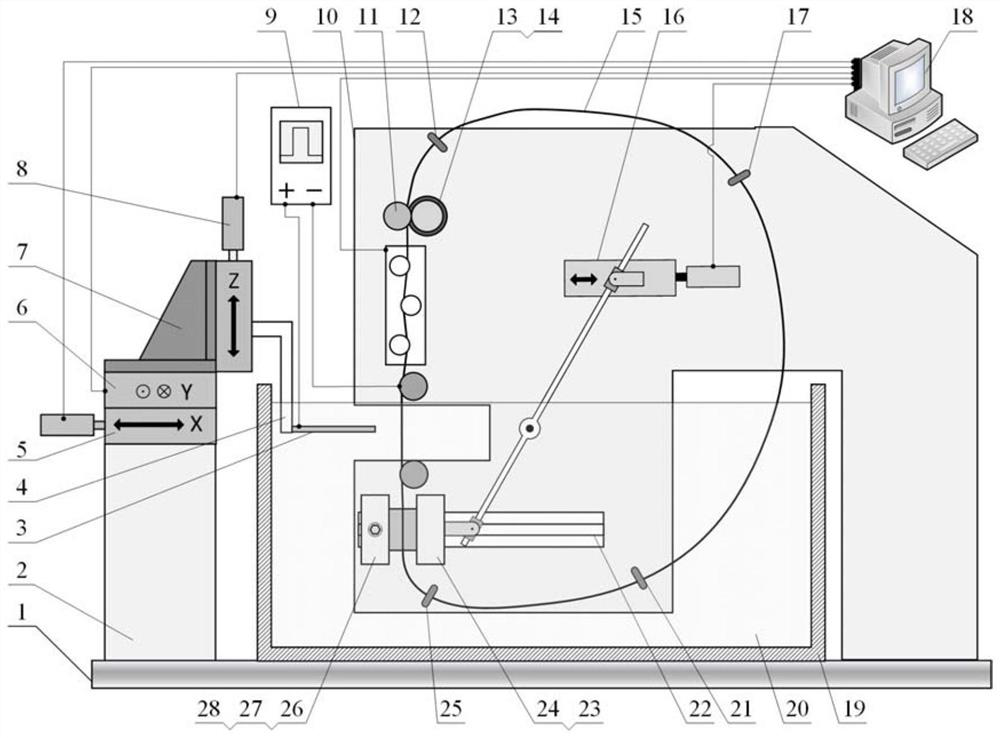

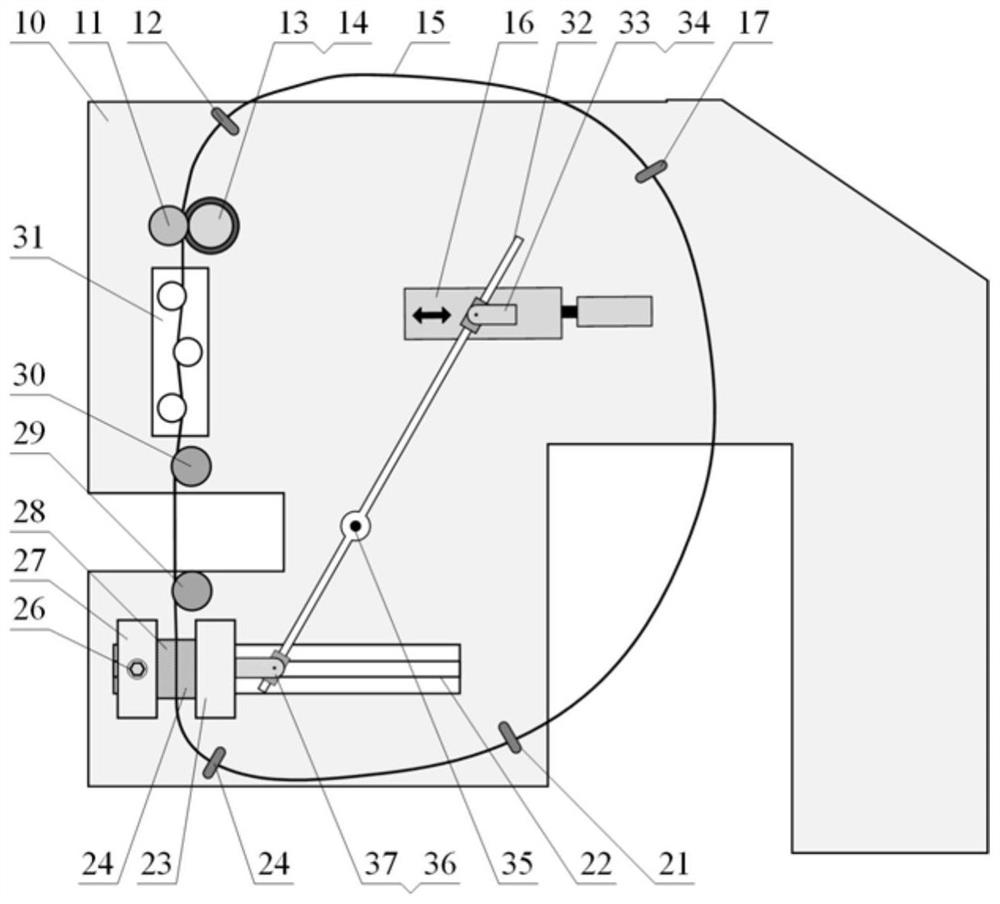

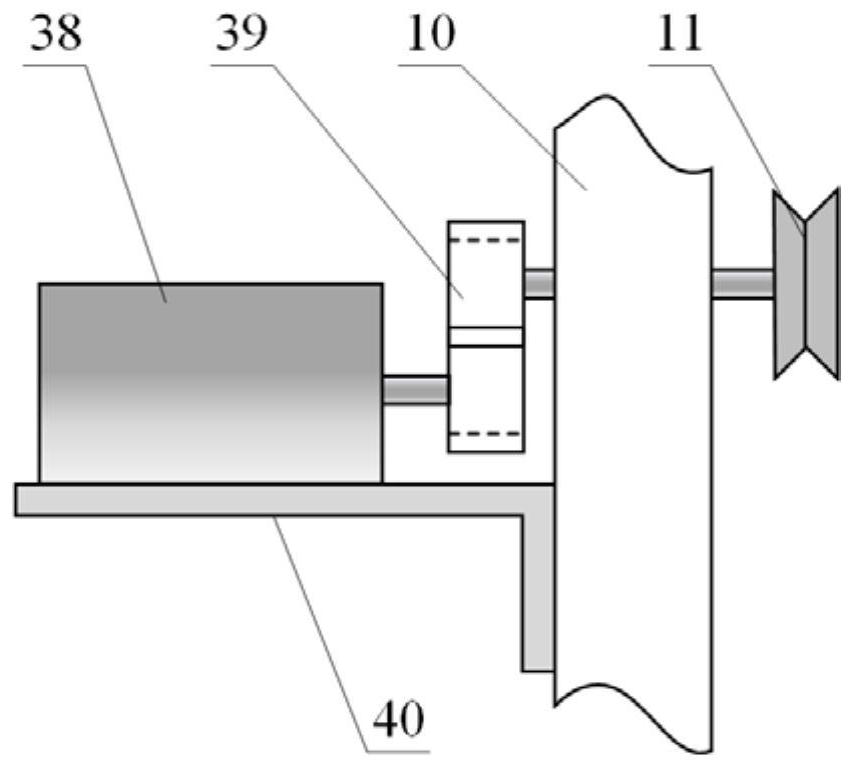

[0031] The one-way circular wire feeding system for electrolytic wire cutting includes a driving wheel 11, an auxiliary wheel 13 and a guide rail 22; the driving wheel 11 and the auxiliary wheel 13 cooperate with each other to drive the circular wire 15 to move, and the guide rail 22 is set On the support plate 10, a first slider 23 is installed on the guide rail 22, a fourth slider 27 is arranged on one side of the first slider 23, and an elastic material is arranged between the first slider 23 and the fourth slider 27 , the elastic material is non-conductive and corrosion-resistant, a part of the annular wire 15 passes through the elastic material, and the movement of the first slider 23 can squeeze or loosen the elastic material so as to compress or loosen the annular w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com