Metallographic coated AC test paper toughness enhancing method

A technology of test paper and film coating, which is applied in the field of toughness strengthening of metallographic film-coated AC test paper. It can solve the problems of relatively strict personnel level requirements, large environmental impact, and high price, and achieve simple use, easy film formation, and low price. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

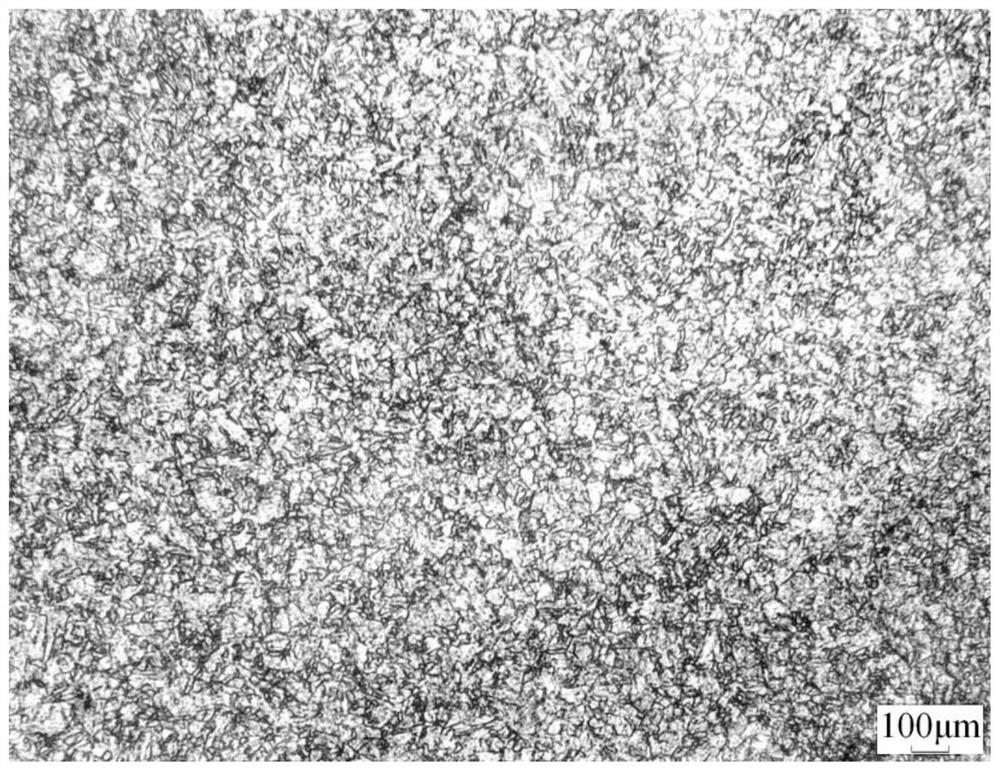

[0028] as attached figure 1 A kind of metallographic coating AC test paper toughness strengthening method shown, this strengthening method comprises the following steps:

[0029] S1. Determine the raw materials, determine the amount of acetone, methyl violet, cellulose diacetate, triphenyl phosphate, and agar in the raw materials required for metallographic coating, and configure the raw materials of scheme 1 and scheme 2 respectively, using acetone, Methyl violet and cellulose diacetate were used to make a contrast mixture to form a contrast test paper;

[0030] S2. For the preparation solution of AC test paper in configuration plan 1, take 80 mg of methyl violet (biological dye reagent) powder, 60 mL of acetone, 3 g of cellulose diacetate, and 5 g of triphenyl phosphate, and place various materials in a sterile solution bottle , using a glass rod to alternately stir the mixed solution in the glass bottle clockwise and counterclockwise, and configure the AC test paper requir...

Embodiment 2

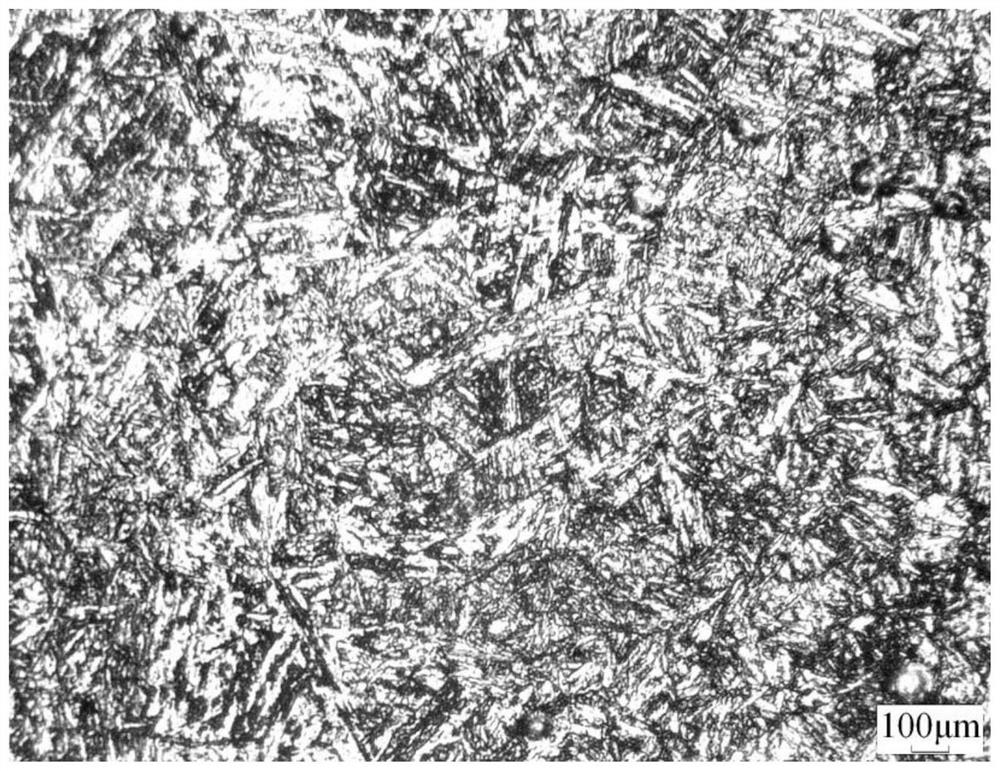

[0035] as attached figure 2 A kind of metallographic coating AC test paper toughness strengthening method shown, this strengthening method comprises the following steps:

[0036] S1. Determine the raw materials, determine the amount of acetone, methyl violet, cellulose diacetate, triphenyl phosphate, and agar in the raw materials required for metallographic coating, and configure the raw materials of scheme 1 and scheme 2 respectively, using acetone, Methyl violet and cellulose diacetate were used to make a contrast mixture to form a contrast test paper;

[0037] S2, the preparation solution of AC test paper in configuration plan 2, take 80mg methyl violet (biological dye reagent) powder, 60mL acetone, 3g diacetate fiber, 3g agar, place various materials in sterile solution bottles, use glass Stir the mixed solution in the glass bottle clockwise and counterclockwise alternately with the rod, and configure the AC test paper required by scheme two;

[0038] S3. Place the solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com