Novel textile machine

A textile machine, a new type of technology, applied in textiles, looms, spinning machines, etc., can solve the problems of inconvenient maintenance and complexity in structural design, and achieve the effect of simple and ingenious structural design and easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

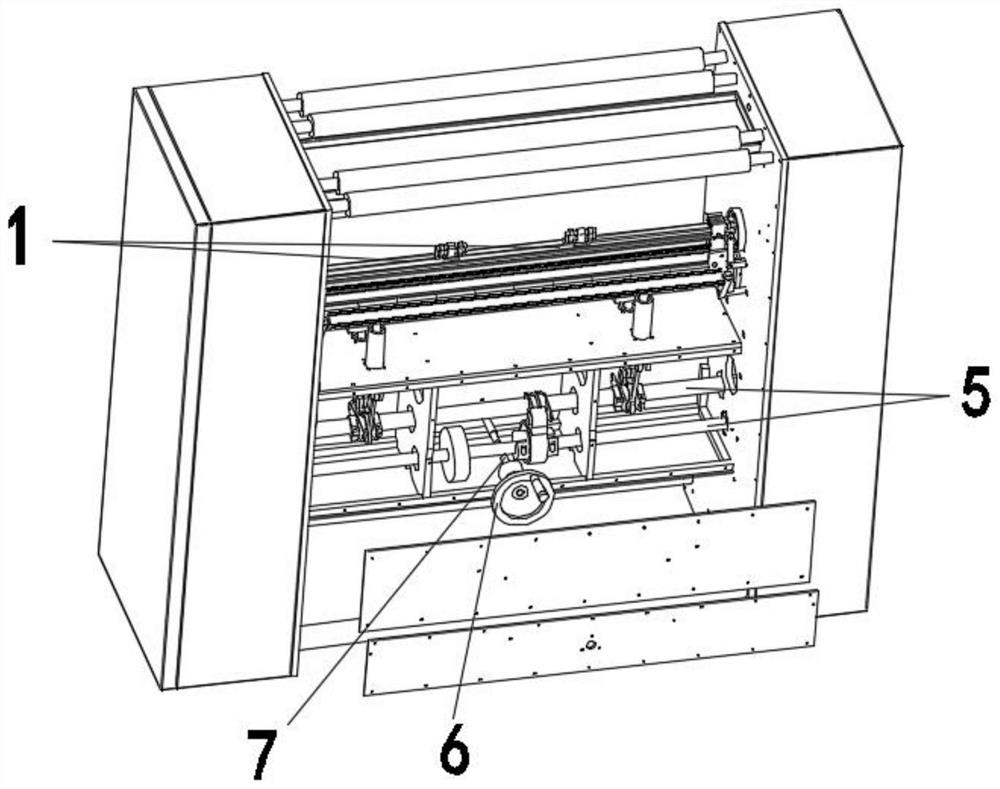

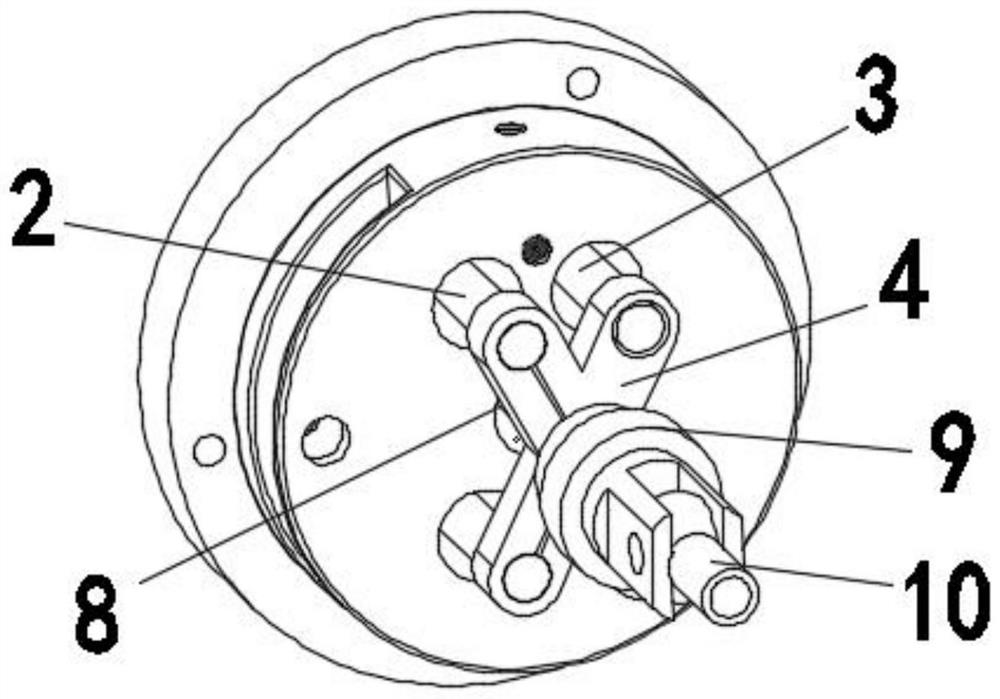

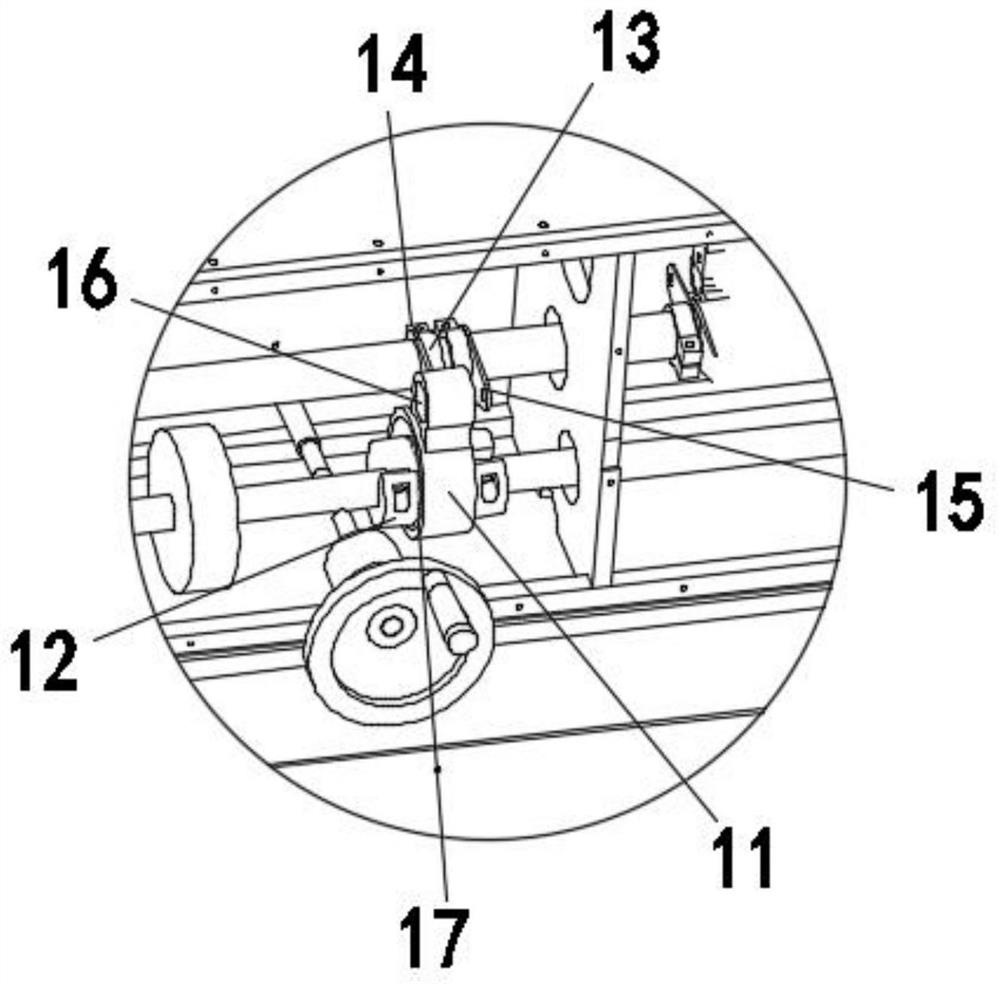

[0013] like Figure 1-Figure 3 As shown, a new type of textile machine includes a wire frame 1, a transmission assembly that drives the wire frame 1 to move, a drive assembly, a roller shaft 5, a linkage assembly and a lifting assembly, and the transmission assembly includes at least a moving rod 2, a static rod 3 and a Holder 4. The wire frame 1 is the anti-jumping wire frame 1, and the drive assembly is connected to the power source, and the two parallel wire frames 1 are driven to move through the transmission assembly. In this embodiment, the wire stand 1 can be shifted relative to parallel and rotated synchronously.

[0014] The moving rod 2 and the cage 4 are axially contacted and linked, and the cage 4 is provided with a through hole for the static rod 3 to pass through, and the cage 4 and the driving assembly are linked in the axial and circumferential directions Cooperate. Generally, the cage 4 is provided with an impermeable jack for the insertion of the driving r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com