Stepless adjusting type bus bar isolation device

A technology of stepless adjustment and isolation device, which is applied in the direction of fully enclosed busbar device, busbar installation, cable installation, etc., which can solve the problem that maintenance personnel are easy to remove or cross the barrier, do not meet the work ticket layout specification, and take a long time to sort out. and other problems, to achieve the effect of convenient and quick assembly and disassembly, enhance the adaptability of the device, and improve the operation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The pole-adjustable bus barrel isolating device of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

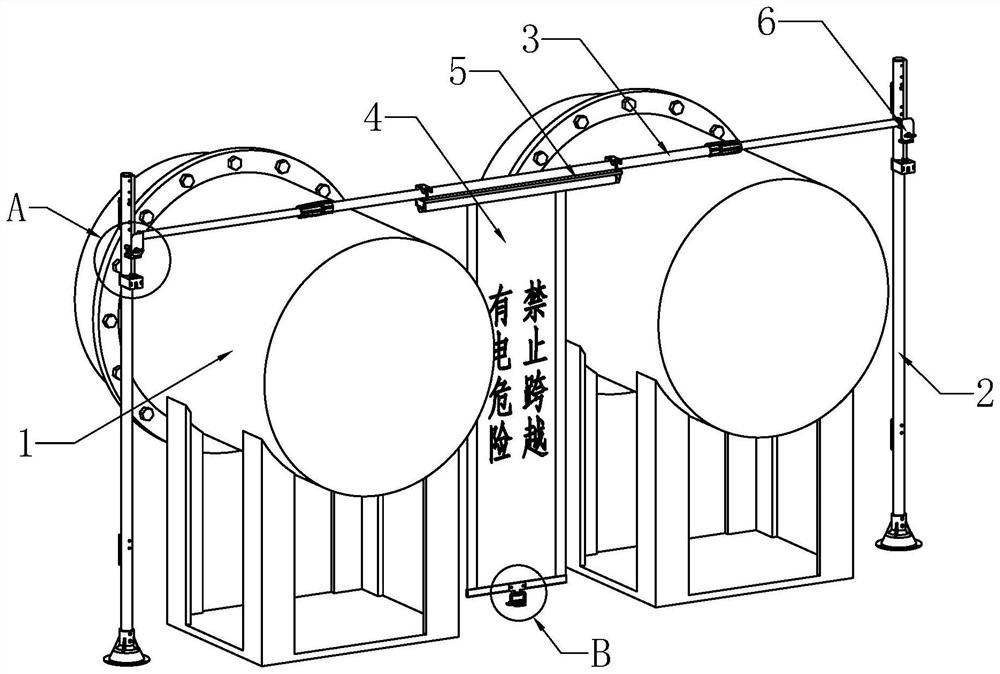

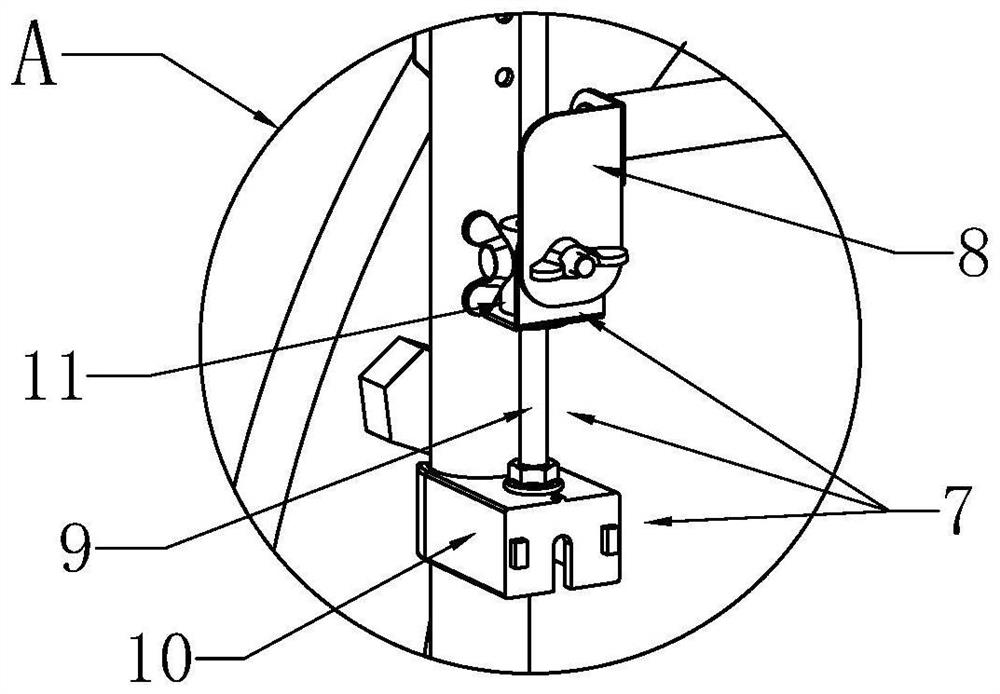

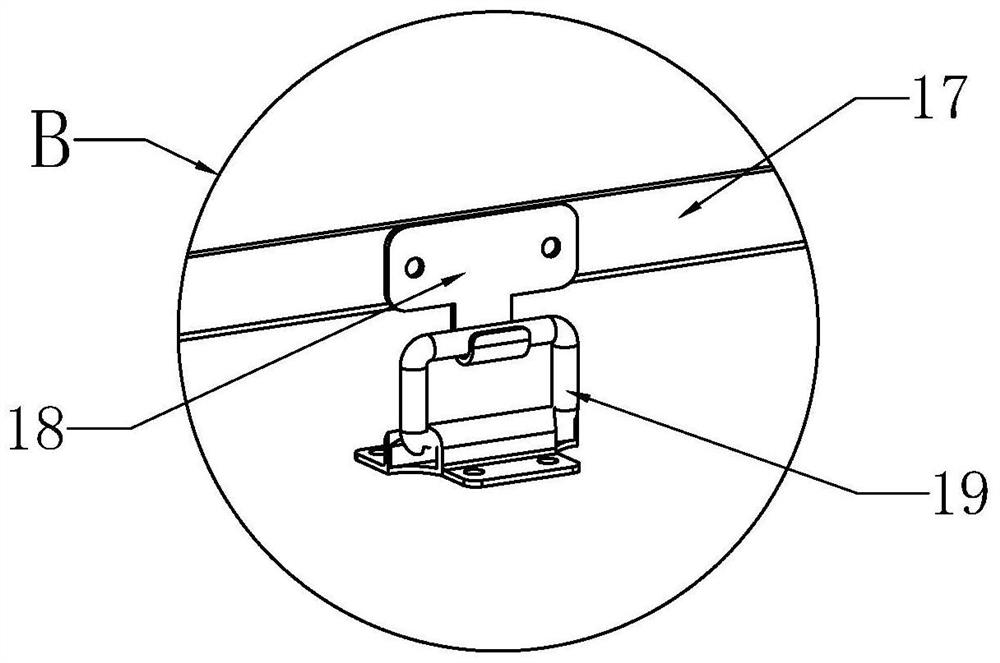

[0027] As shown in the figure, the pole-adjustable bus barrel isolating device of the present invention includes a device that can be vertically placed on the outside of two bus barrels 1 (such as figure 1 The two columns 2 on the left and right edges in the direction shown), the cross brace 3 that is located above the two busbars 1 and can be used to connect between the two columns, and the warning device 4 for information display, wherein, The bottoms of the two uprights 2 are provided with a base respectively, through which the uprights can be fixedly installed on the ground to improve the stability of use. The said cross brace 3 is preferably a telescopic tube, and the left and right ends of the cross brace 3 are The clamping device 6 is connected between the upper parts of the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com