Clothes folding machine

A garment folding machine and frame technology, which is applied in the field of garment folding, can solve the problems of low folding efficiency, long clothing transportation distance, and high height of the garment folding machine, and achieve the effect of compact structure, space saving, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

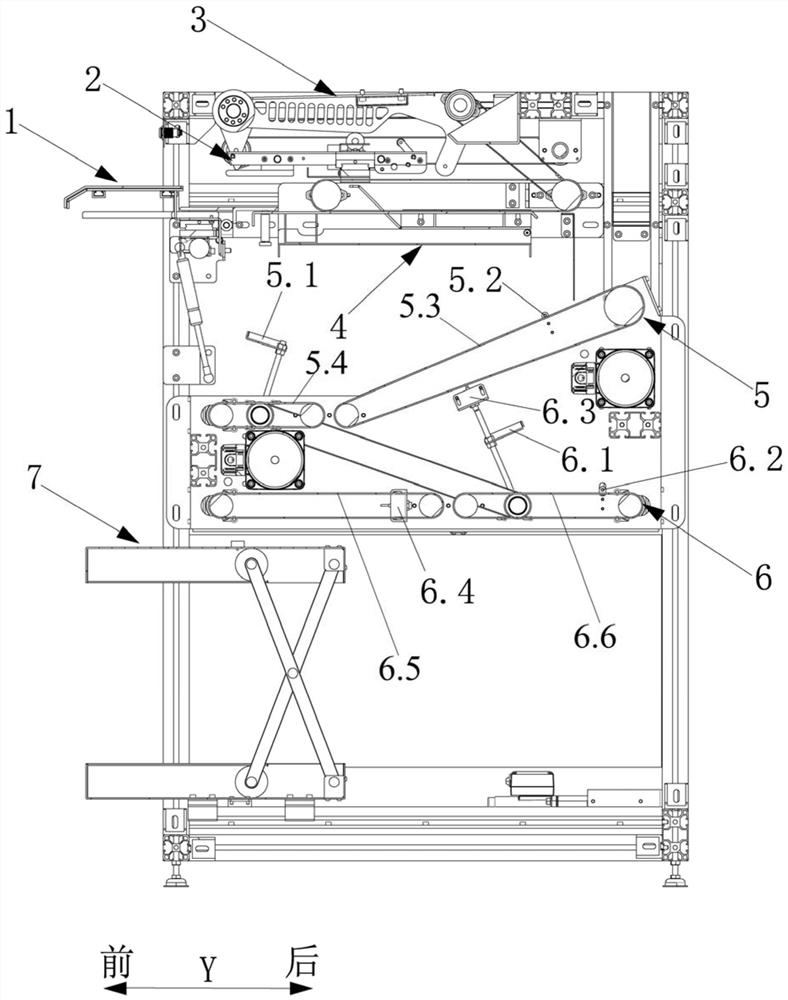

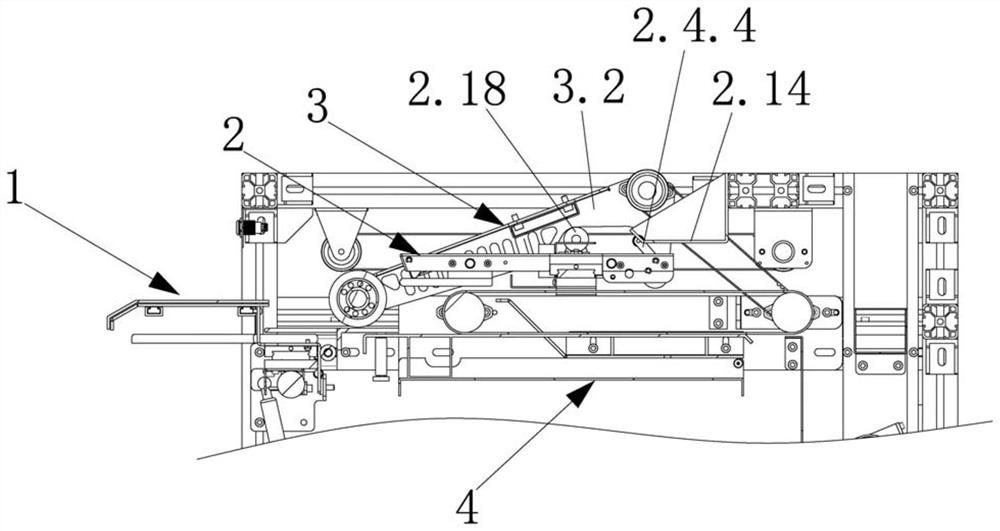

[0100] Such as figure 1 As shown, the clothes folding machine includes a loading system, a length folding device, an unloading device, an operation panel (not shown in the figure) and a controller. The loading system includes a first width folding device 1 , a traction device 2 , a feeding device 3 and a second width folding device 4 . The length folding device includes a first length folding device 5 and a second length folding device 6 .

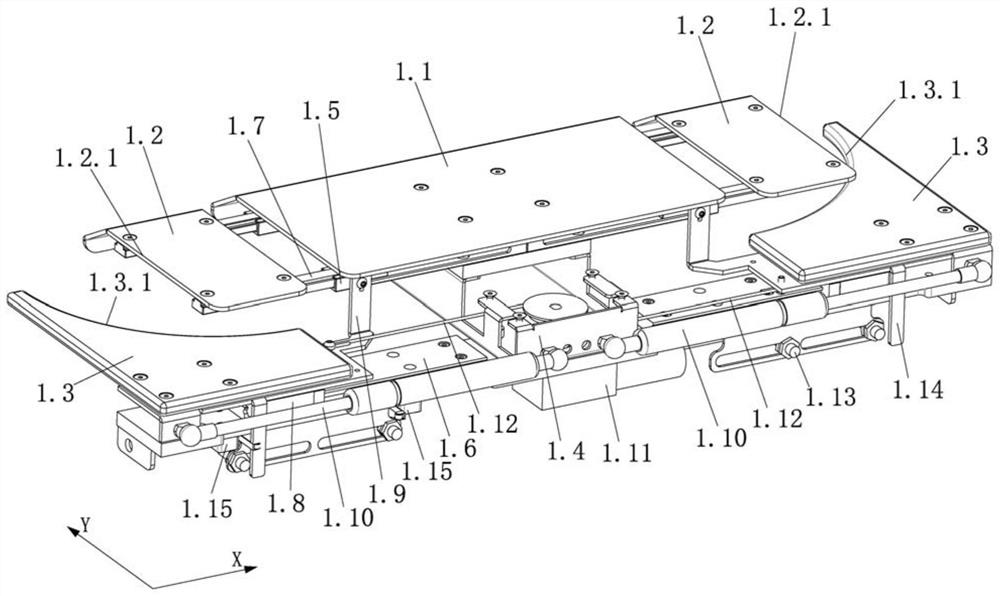

[0101] Such as Figure 3-5As shown, the first width folding device 1 includes a base 1.4, a support plate 1.1 is installed on the base 1.4, a first moving plate 1.2 is provided at the left and right ends of the support plate 1.1, and the outer end of the first moving plate 1.2 has a second A folding edge 1.2.1, the front ends of the support plate 1.1 and the two first moving plates 1.2 are all provided with inclined surfaces 1.1.1, and the first folding edge is parallel to the Y-axis direction (the length direction of the folded clothes)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com