Prefabricated corrugated steel-concrete deck type bridge and construction method thereof

A prefabricated and corrugated steel technology, applied in the erection/assembly of bridges, bridges, bridge parts, etc., can solve the problems of slow on-site pouring construction and insufficient bearing capacity of arch bridge structures, reducing formwork construction, strong spanning ability, and convenient connection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

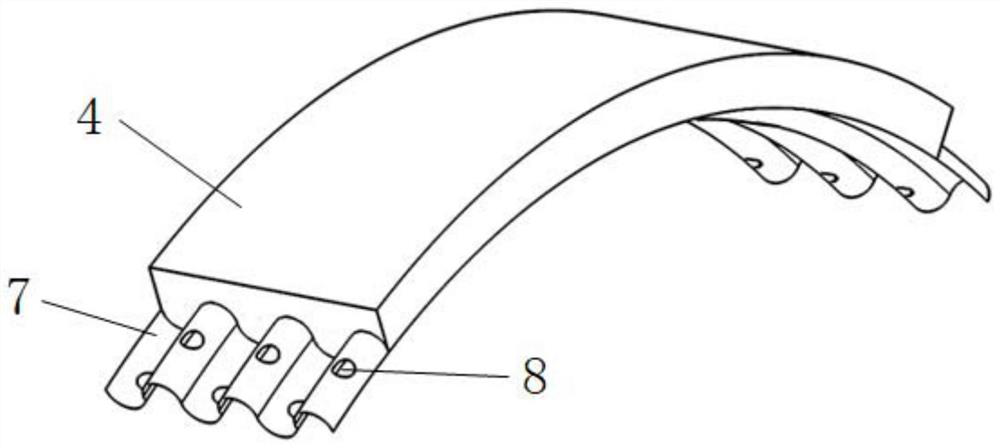

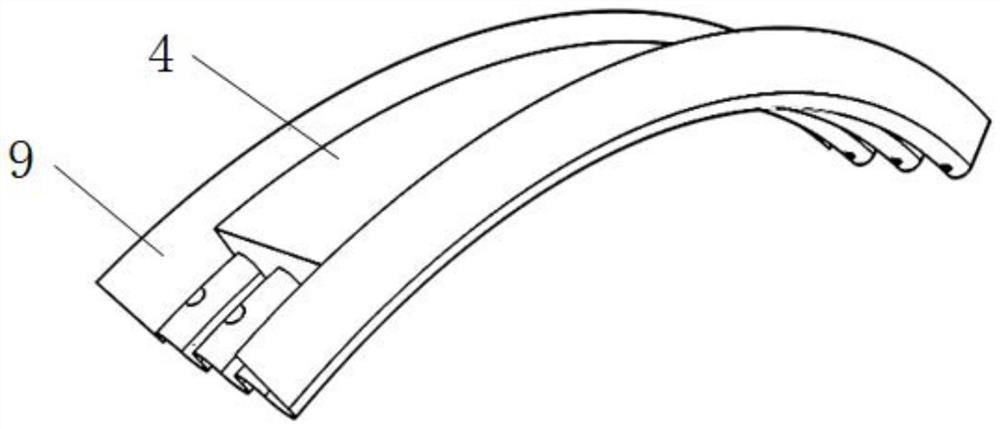

[0037] Embodiment 1: The prefabricated corrugated steel-concrete top-supported bridge in this embodiment includes a corrugated steel-concrete arch 1, a plurality of columns 2 and a bridge deck 3, wherein the corrugated steel-concrete arch 1 is made of multi-section prefabricated corrugated steel - Concrete segments 4 are connected, and a column head 5 is arranged on the upper surface of part of the prefabricated corrugated steel-concrete segment 4 to form a prefabricated corrugated steel-concrete segment 6 containing the column head. The column 2 is erected on the column head 5, and the column 2 The bridge deck 3 is erected on the column top surface;

[0038] The prefabricated corrugated steel-concrete segment 4 is a single-layer corrugated steel-concrete structure or a double-layer corrugated steel-concrete structure, the single-layer corrugated steel-concrete structure is poured with concrete on the surface of the single-layer corrugated steel 7, and the double-layer corrugat...

specific Embodiment approach 2

[0040] Embodiment 2: This embodiment is different from Embodiment 1 in that the steel plate surface of the concrete poured on the corrugated steel 7 in the prefabricated corrugated steel-concrete segment 4 is uniformly provided with shear studs.

[0041]For the corrugated steel plate-concrete segment proposed in this embodiment, the corrugated steel plate needs to be welded with shear studs to increase the connection between the corrugated steel and the concrete, and prevent disengagement during the stress process, which affects the mechanical performance; During the assembly process, the connection of corrugated steel plates must meet the requirements of "Corrugated Steel Tubes (Plates) for Highway Culvert Passages" (JTT791-2010).

specific Embodiment approach 3

[0042] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the corrugated structure of the corrugated steel 7 in the prefabricated corrugated steel-concrete section 4 extends along the width direction of the bridge.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Carrying capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com