Offshore wind power truss concrete cylindrical foundation

A cylindrical foundation and offshore wind power technology, applied in the direction of basic structure engineering, construction, etc., can solve the problems of complex load transmission methods of the transition section and the bottom plate, which cannot be fully utilized, and the buckling of the outer warehouse plate is easy to achieve, which is conducive to popularization Utilization, high construction efficiency, and the effect of improving horizontal bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

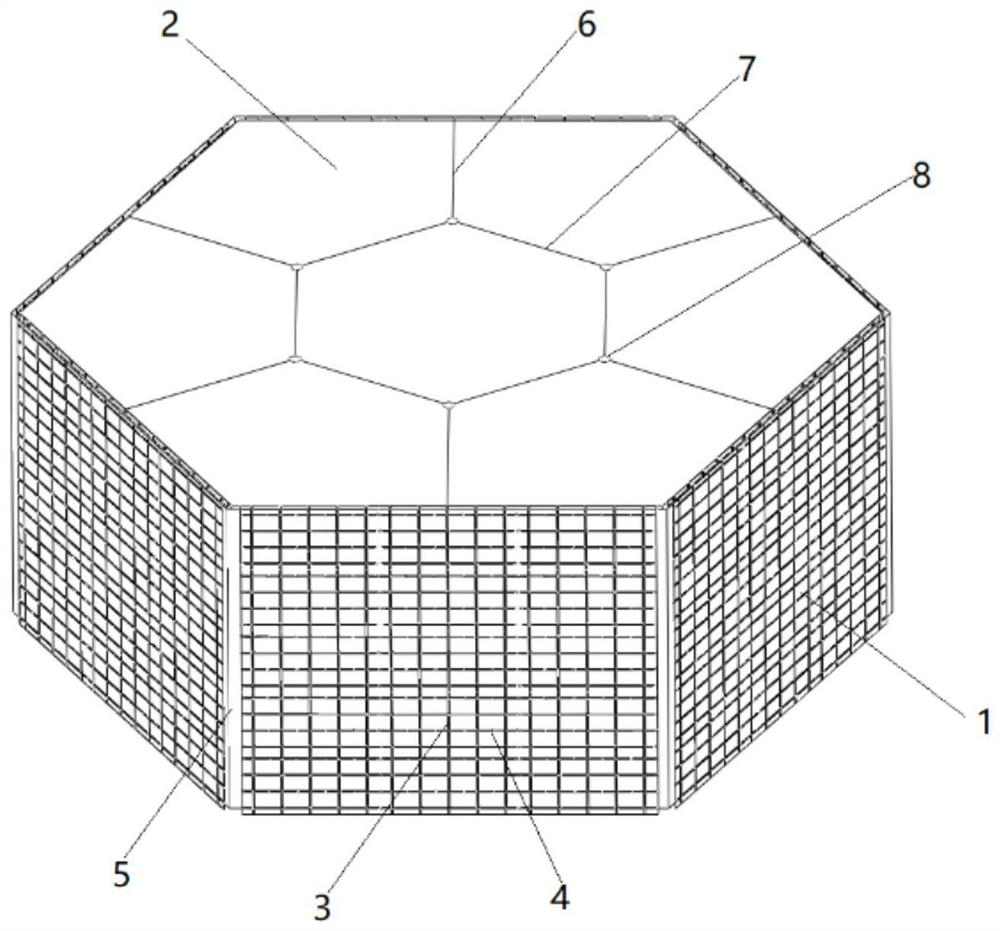

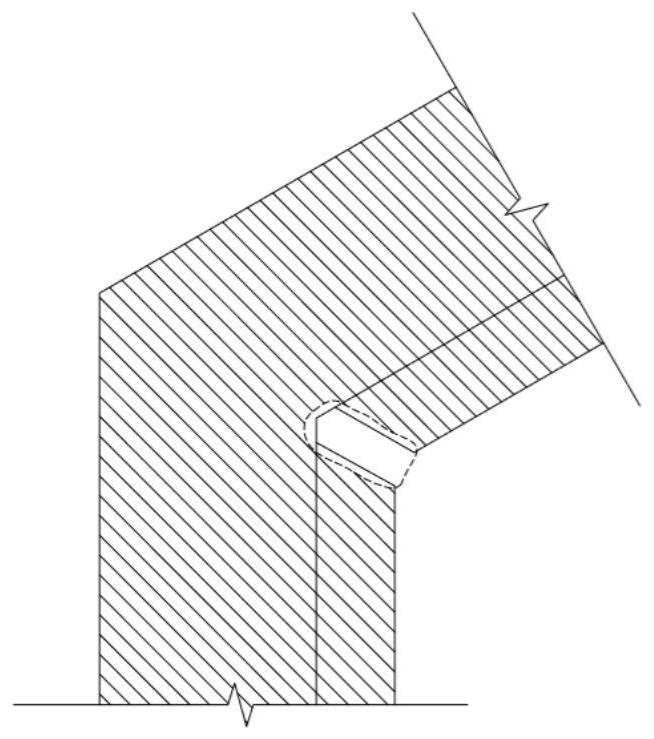

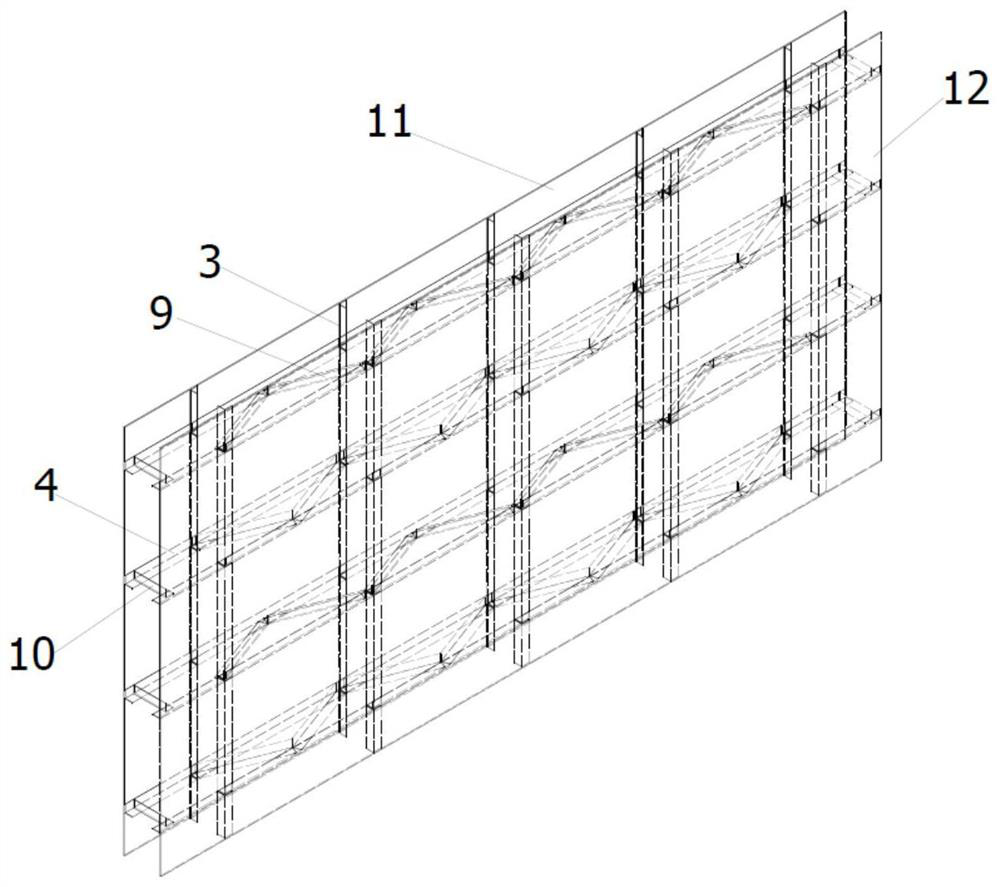

[0022] like Figure 1-4 As shown, an offshore wind power truss concrete tube foundation of the present invention includes a polygonal tube wall, and the polygonal tube wall is assembled from a plurality of steel truss concrete composite tube wall modules 1 of the same structure, without the need for whole plate welding, and the construction efficiency is high ; In this embodiment, the steel truss concrete composite cylinder wall module 1 includes the module inner cladding steel 11, the module outer cladding steel 12, the vertical stiffener 3, the transverse stiffener 4, the oblique stiffener 9 and the tension support 10, the module Concrete is filled between the inner cladding steel 11 and the module outer cladding steel 12, the module inner cladding steel 11 and the module outer cladding steel 12 are evenly provided with a plurality of horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com