Scroll compressor

A scroll compressor and movable scroll technology, which is applied in the field of scroll compressors, can solve the problems of easy wear of wear-resistant coatings and easy wear of contact surfaces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The following descriptions of various embodiments of the present invention are exemplary only, and in no way limit the present invention and its application or usage. The same reference numerals are used to denote the same types of components in the respective drawings, and the configuration of the same components will not be described repeatedly.

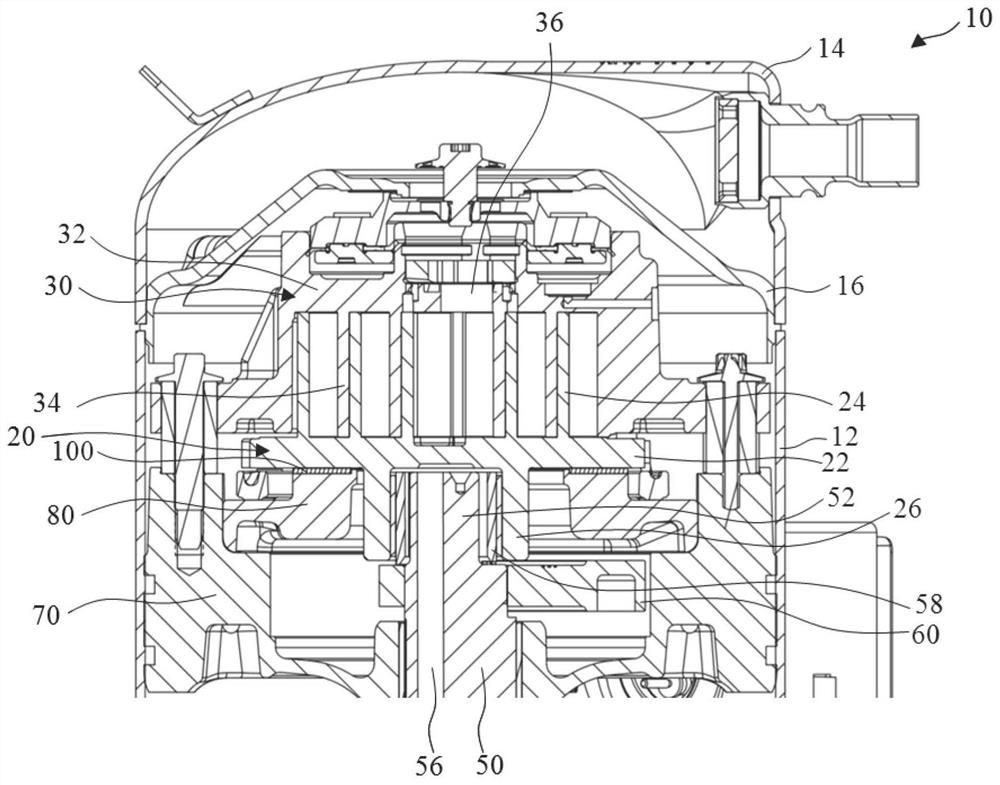

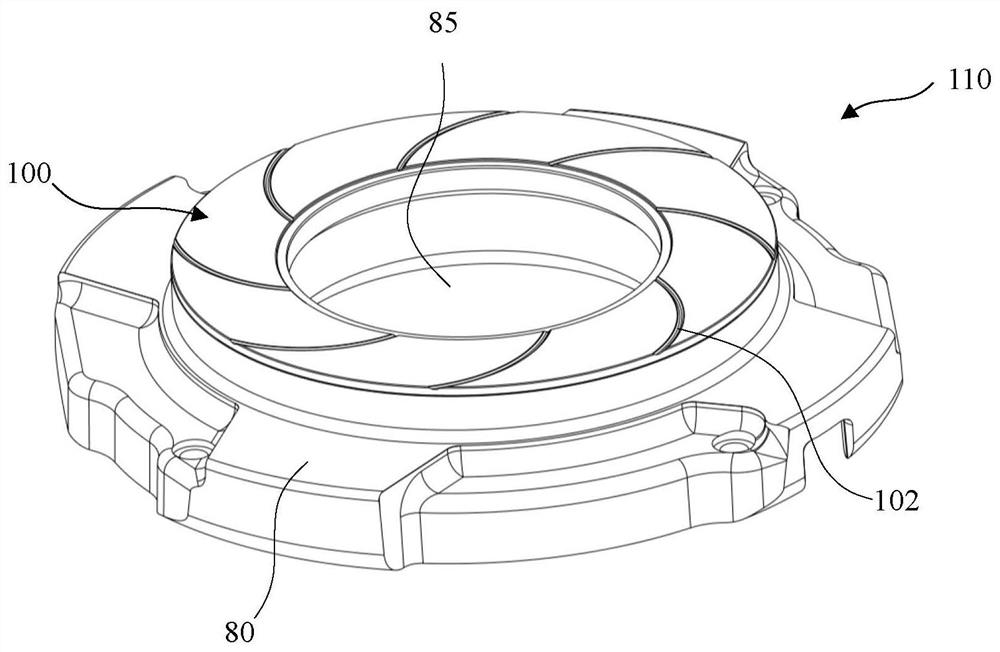

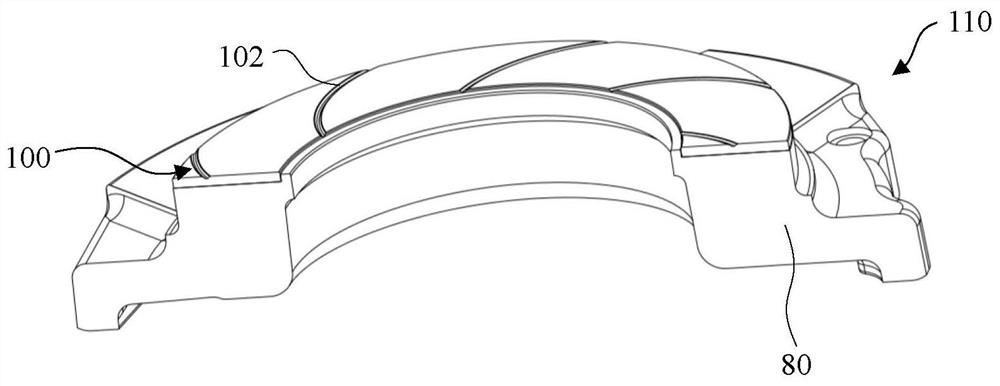

[0052] will now refer to figure 1 The basic construction and operating principle of the scroll compressor according to the present invention will be described. Scroll compressor 10 includes a generally cylindrical housing 12 . An intake joint (not shown) is provided on the shell 12 for sucking in low-pressure gaseous refrigerant. One end of the shell 12 is fixedly connected with an end cover 14 , and the other end is fixedly connected with a bottom cover (not shown). The end cap 14 is fitted with a discharge connection for discharging the compressed refrigerant. A partition 16 extending transversely relative to the casin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com