Cemented filling body damage evaluation method

A technology of cement filling and evaluation method, which is applied in material analysis using sonic emission technology, preparation of test samples, and testing material strength by applying stable tension/pressure. Problems such as the speed and slowness of the internal damage of the filling body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] A method for evaluating the damage of a cemented filling body, comprising the following steps:

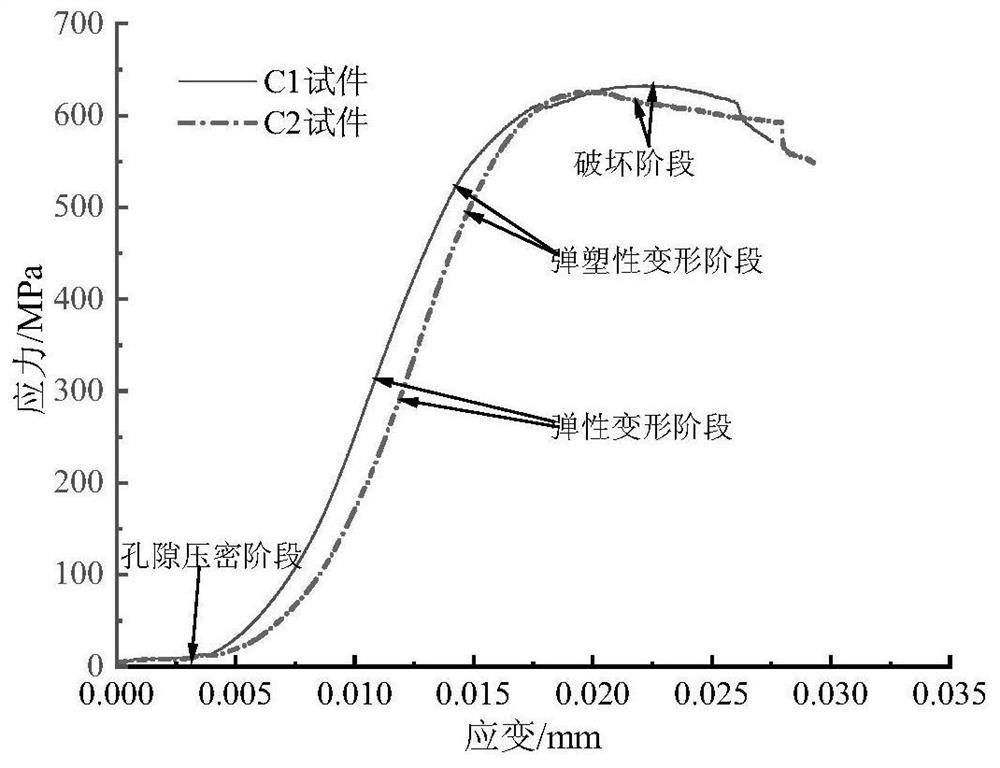

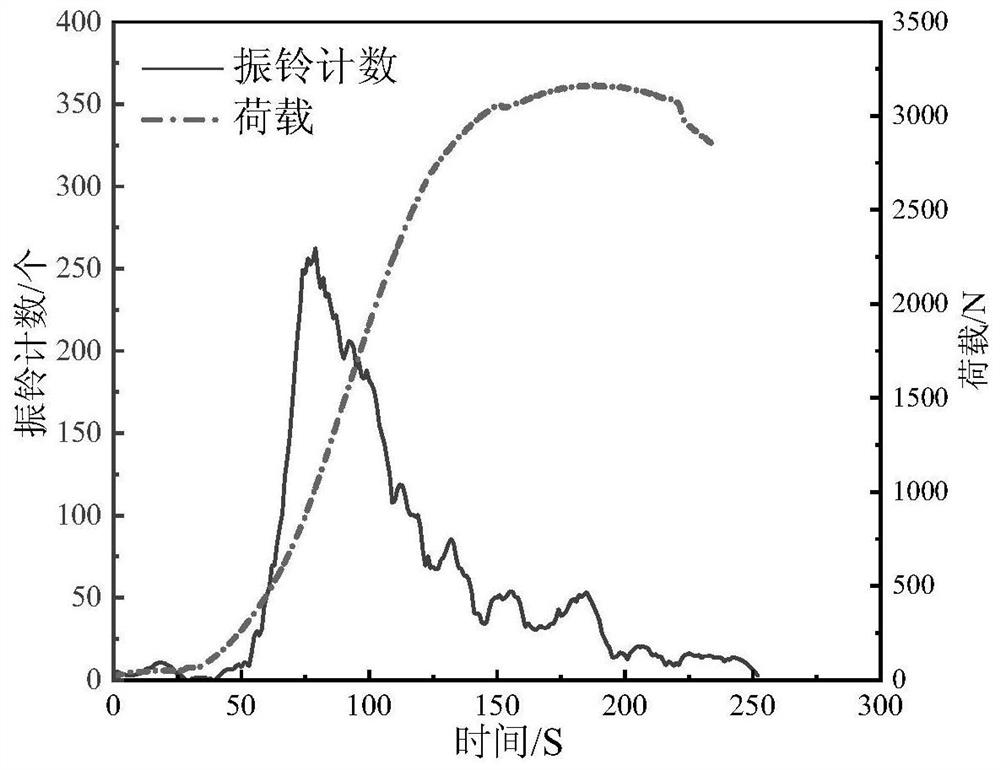

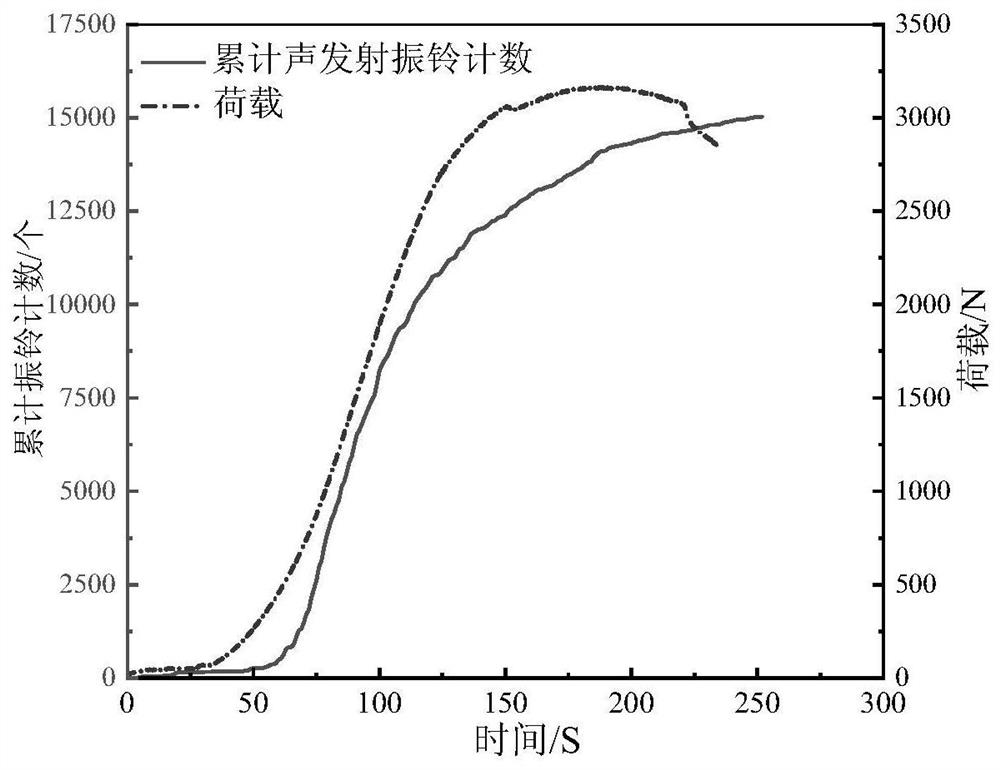

[0027] Step 1. Take a sample of the filling body in a metal mine, conduct an indoor uniaxial compression test on the sample after processing and grinding, use an instrument to perform a uniaxial compression test to measure the mechanical properties of the sample, and record the stress-strain and acoustic emission of the sample Ring count, cumulative ring count experimental data. The filling body sample in this example is taken from the whole tailings production sample of a metal mine in Henan, China. The production process and curing conditions are in line with the requirements of the official version of the "Ordinary Concrete Mix Proportion Design Regulations" in JGJ55-2011. The mechanical parameters and acoustic emission parameters of the sample were measured in the experiment. Table 1 records the time, ringing count, cumulative ringing count and energy data during the loa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com