A direct plug-in optical fiber connector

An optical fiber connector and in-line technology, applied in the field of optical fiber communication, can solve problems such as large insertion loss and low construction efficiency, and achieve the effects of improving stability, saving materials, and improving positioning stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

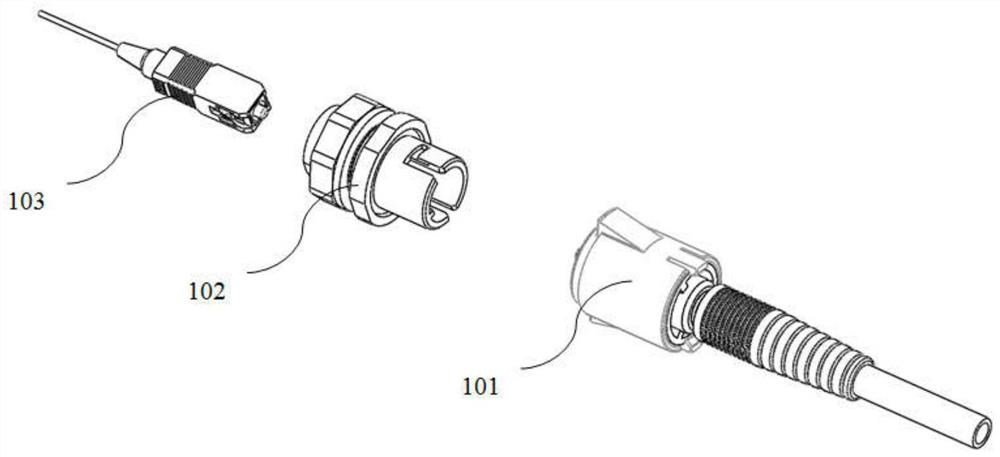

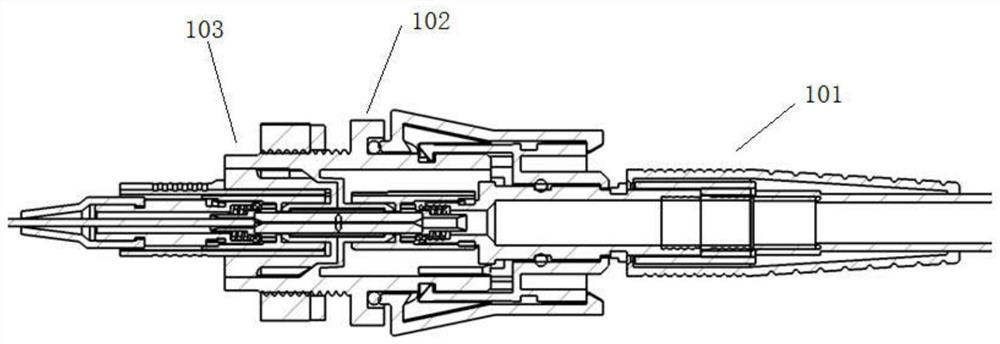

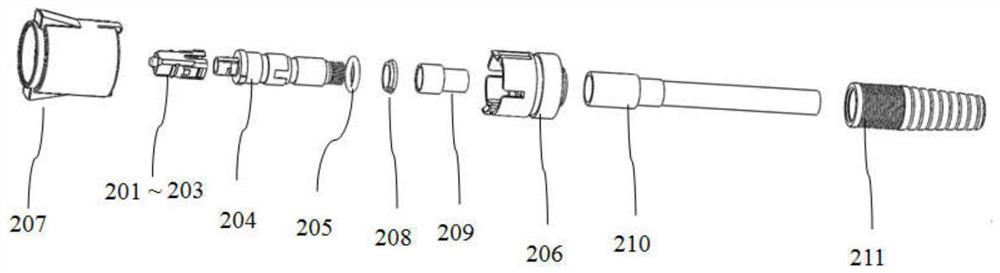

[0027] like Figure 1-8As shown, an in-line optical fiber connector includes an in-line optical fiber connector plug 101 and an SC optical fiber standard connector 103, and the in-line optical fiber connector plug 101 and the SC optical fiber standard connector 103 are connected by an optical fiber adapter 102. The in-line fiber optic connector plug 101 includes a SC connector inner standard kit formed by the combination of an optical fiber, an inner sleeve 201, a φ2.5 ferrule (including a tail handle) 202, and an inner sleeve spring 203, a cylindrical inner long handle 204, a docking The sleeve 206 , the sealing sleeve 207 , the limit ring 208 , the copper pressure ring 209 , the heat shrinkable tube 210 and the tail sleeve 211 . The end of the inner sleeve spring 203 of the above-mentioned SC connector inner standard kit is connected to the left end of the inner long handle 204, the other end of the SC connector inner standard kit is used to connect with the optical fiber ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com