Air curtain cover of laser cutting equipment

A laser cutting and equipment technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of dragging the laser head, high cost, and high energy consumption, so as to avoid component fatigue, reduce energy consumption, and work reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

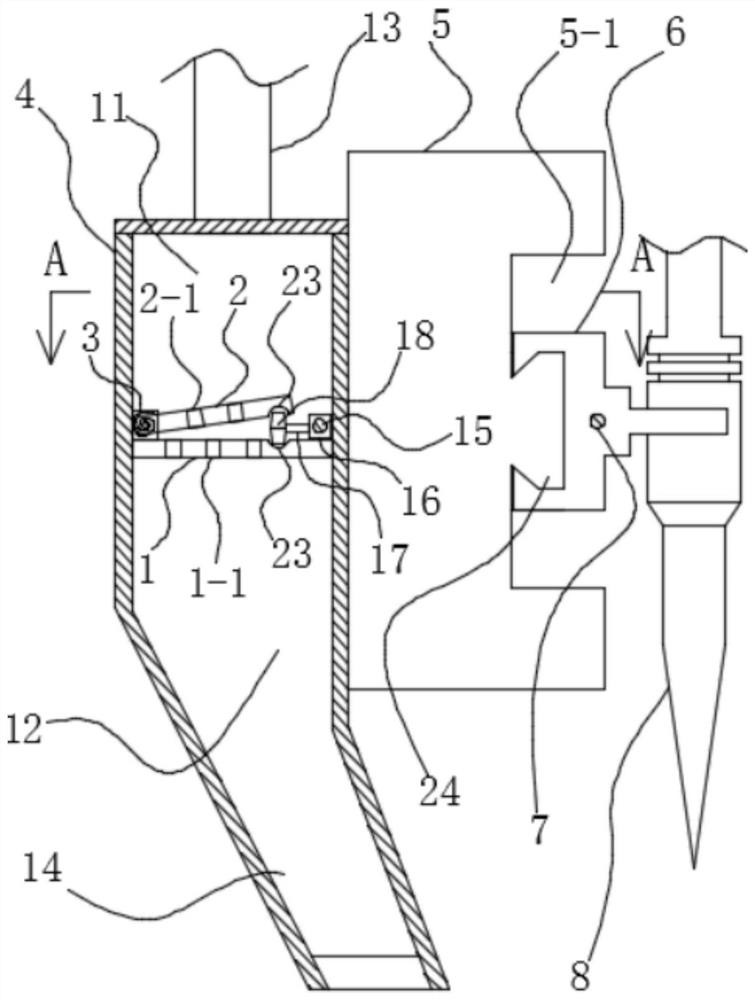

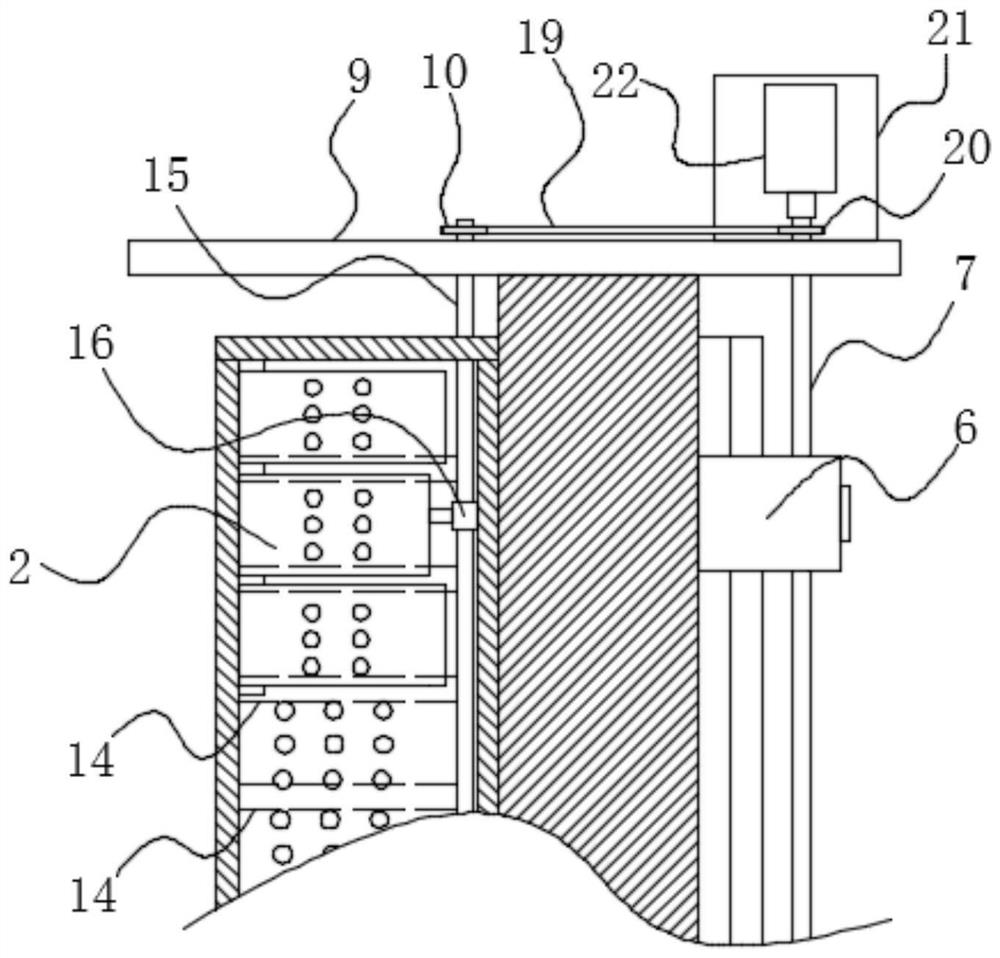

[0022] like figure 1 and figure 2 As shown, the branch plate 9 is fixed to both ends of the tap 5, and the groove 5-1 is opened on the side surface of the stringer 5-1, and the groove 5-1 has a tail slide rail 24. The connecting seat 6 is located in the recess 5-1 of the tap 11, and the connecting seat 6 is slidable with the rail 24. The connecting seat 6 extends extends having a mount 6-1, the connecting seat 6, and the mount 6-1 are integrally formed, and the laser head 8 is c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap