Beet breakage-proof balanced feeding device for sugar production and application method

A feeder, equalization technology for conveyor controls, transport and packaging, loading/unloading, etc., to solve problems such as beet damage, difficulty in achieving equalization and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

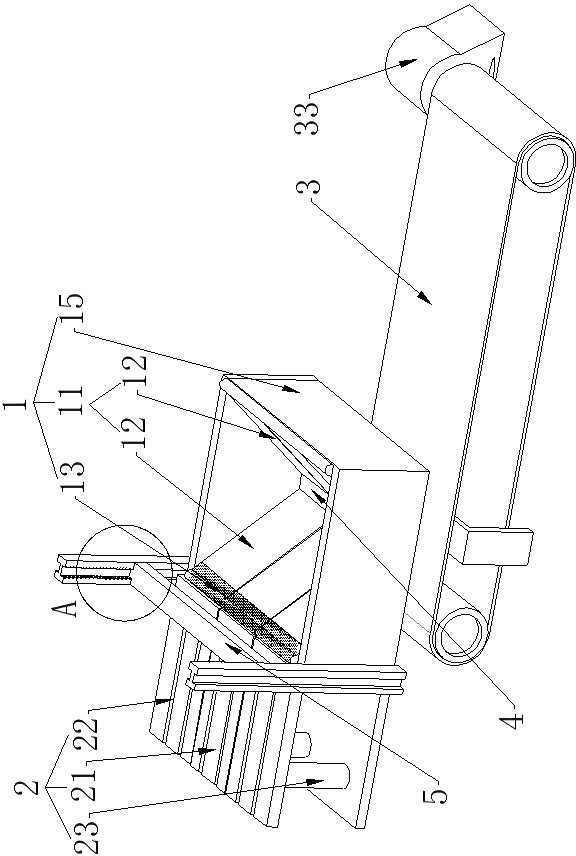

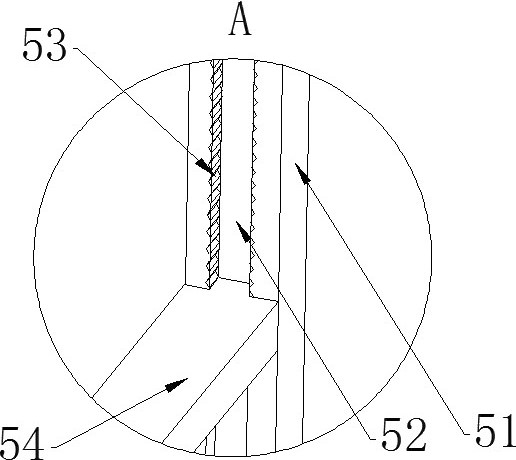

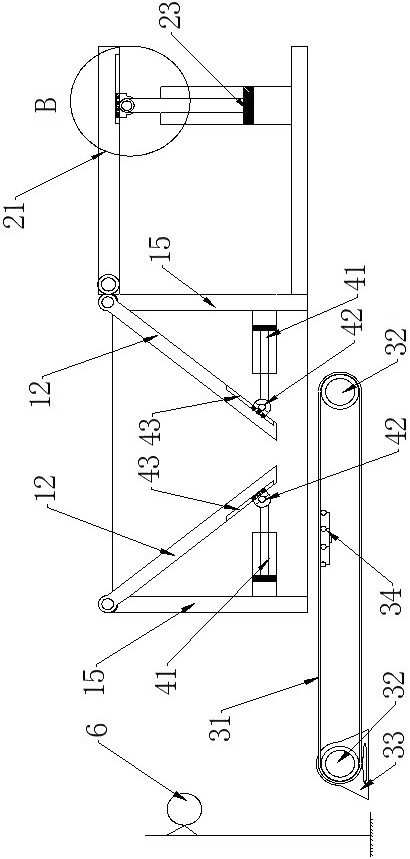

[0044] like figure 1 , figure 2 , image 3 and Figure 4 Shown: the sugar beet anti-damage balanced feeding device for sugar production, which is equipped with a vegetable cellar 1, a rollover unloading platform 2 and a feeding mechanism 3, the rollover unloading platform 2 is movably connected to the side of the vegetable cellar 1, and the feeding mechanism 3 It is arranged below the vegetable cellar 1; the vegetable cellar 1 includes a three-section vegetable hopper 11, and an adjusting opening and closing mechanism 4 is independently arranged at the lower end of the three-section vegetable hopper 11, and the adjusting opening and closing mechanism 4 is arranged opposite to the feeding mechanism 3, and the vegetable hopper 11 is provided with at least one inclined side plate 12, and the inclined side plate 12 is arranged close to the rollover unloading platform 2, and a buffer plate body 13 is arranged on the top of the inclined side plate 12.

[0045] The above vegetabl...

Embodiment 2

[0065] like Figure 5 As shown: in the case that other structures and methods are the same as those in Embodiment 1, as a deformation, the inclined side plate 12 is fixedly arranged on the installation frame 15, and a discharge port is provided between the two inclined side plates 12, and the opening is adjusted. The closing mechanism 4 is provided with a cylinder mechanism b44, and an opening and closing baffle 45 is fixedly installed on the output sheet of the cylinder mechanism b44. The opening and closing effect is the same as that of the first embodiment, but the opening and closing methods are different, and the energy consumed in the opening and closing process is also less.

Embodiment 3

[0067] like Figure 6 As shown: in the case that other structures and methods are the same as those in Embodiment 1, as a deformation, the inclined side plate 12 is fixedly arranged on the installation frame 15, and a discharge port is provided between the two inclined side plates 12, and the opening is adjusted. The closing mechanism 4 includes a sliding opening and closing plate 46 and a cylinder block 47, the cylinder block 47 is arranged on the bottom of the inclined side plate 12, and the sliding opening and closing plate 46 is slidably installed in the cylinder block 47, and the sliding opening and closing plate 46 interacts with the cylinder block 47. It has the same opening and closing function as that of Embodiment 1, but the opening and closing method is different, the structural moving parts are less and more stable, and the energy consumed in the opening and closing process is also less.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com