Rewinding machine for polyimide film processing

A polyimide film and rewinding machine technology, applied in the field of rewinding machines, can solve the problems that the rewinding machine cannot effectively control the rewinding tension, cannot prevent the flattening of folds and wrinkles, and the loosening of the rewinding machine, so as to improve the rewinding ability. Roll quality, increase tension and ensure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

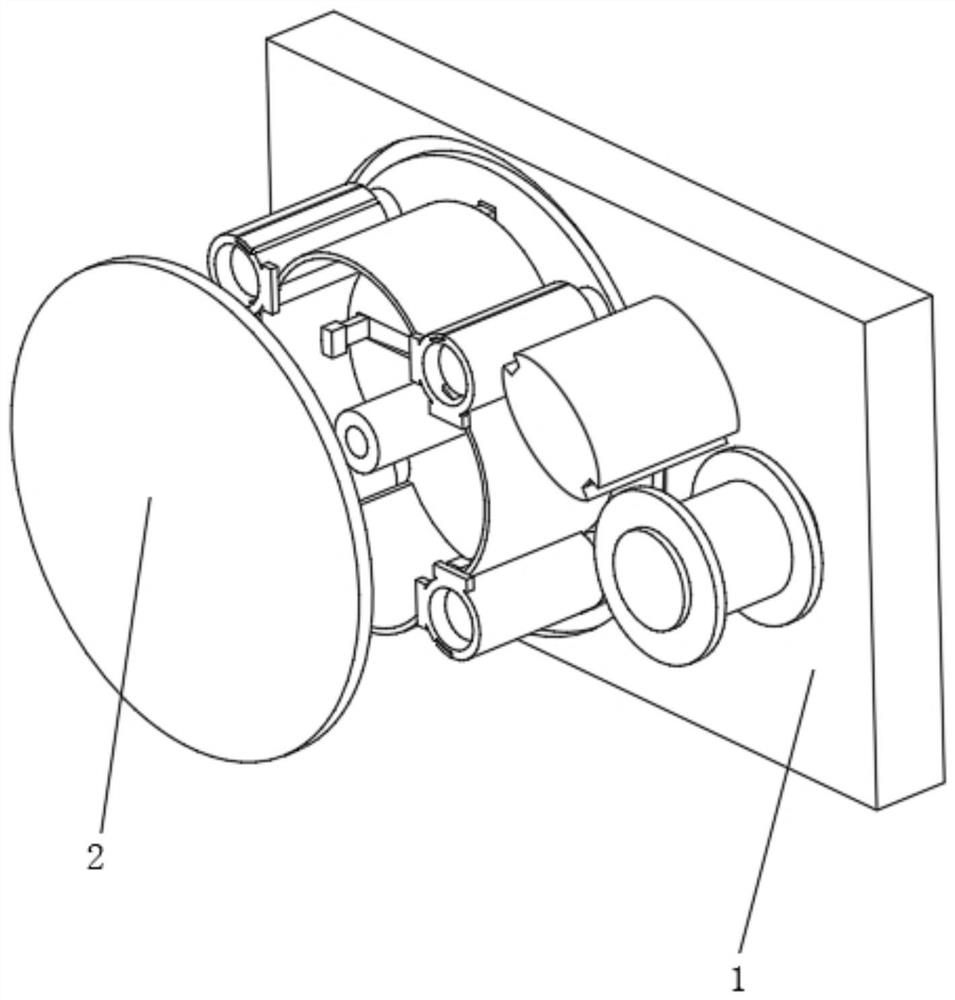

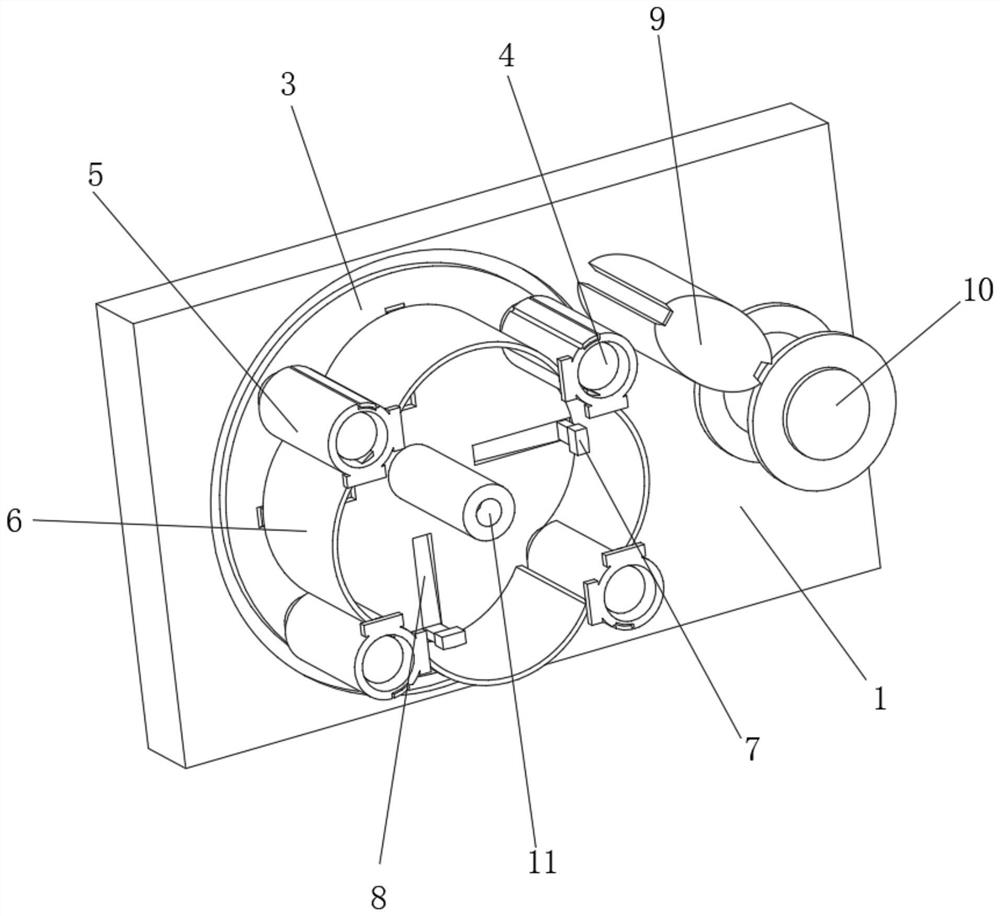

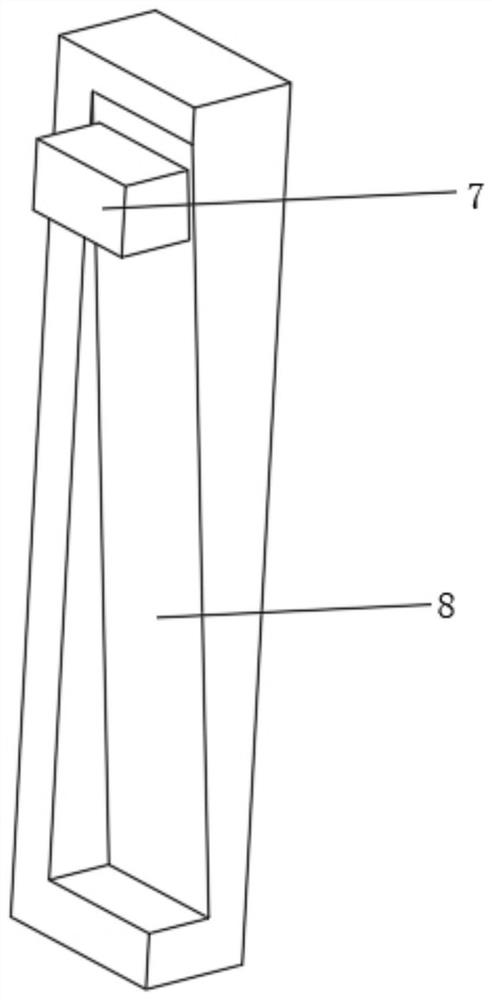

[0034] Such as Figure 1-3 As shown, the present invention provides a technical solution: a rewinder for polyimide film processing, including an installation carrier 1, the front of the installation carrier 1 is correspondingly provided with an installation cover 2, and the installation carrier 1 The front of the drive plate 3 is provided with a driving disc 3, and the surroundings of the front of the driving disc 3 are uniformly fixedly connected with a restricting plunger 4, and the inside of the restricting plunger 4 runs through and is slidably connected with a rewinding carrying wheel 5, two rewinding carrying wheels 5 The positions between them are all provided with forming auxiliary plates 6, and the middle position inside the forming auxiliary plates 6 is fixedly connected with limiting inserting rods 7, and the surroundings of the front of the mounting carrier plate 1 and the inner sides of the rewinding wheel parts 5 are evenly provided with limit slides. Slot 8, lim...

Embodiment 2

[0036] Such as Figure 4-5 Shown, on the basis of embodiment one, the present invention provides a kind of technical scheme: a kind of rewinding machine that is used for polyimide film processing, rewinding carrying wheel part 5 comprises carrying sleeve 51, carrying sleeve 51 The inside of the sleeve is sleeved on the outside of the limit insertion rod 4, and one side of the front side of the carrying sleeve 51 is fixedly connected with a moving track 52, and the inside of the moving track 52 is slidably connected with an adjustment block 53.

[0037] The outer end surface of the adjustment block 53 is fixedly connected with the forming auxiliary plate 6 , the bottom end of the adjustment block 53 located inside the moving track 52 is fixedly connected with a squeeze spring 54 , and the outer surface of the carrying sleeve 51 is provided with a snap-in terminal 55 . Increase the tension of the film as a whole to ensure the stability after rewinding.

Embodiment 3

[0039] Such as Figure 6-8As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: a rewinder for polyimide film processing, the leveling mechanism 9 includes a support outer plate 91, and the support outer plate The upper and lower ends of the front of 91 are fixedly connected to the limit cover 92, and the position near the output end above the support outer plate 91 is rotatably connected to the discharge pinch wheel 93, and the output end inside the limit cover 92 is fixed below the discharge pinch wheel 93. Wipe pressing sheet 94 is connected. Prevent impurities on the surface of the film from being damaged under the action of rewinding tension, and ensure the cleanliness of the film.

[0040] The front side of the supporting outer plate 91 and close to the input end is rotatably connected with a feed rotary rod 95 , and the middle position of the front side of the supporting outer plate 91 is fixedly connected with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com