A printed circuit board processing method applied in 5g industrial internet

An industrial Internet and printed circuit board technology, applied in separation methods, chemical instruments and methods, electrolytic components, etc., can solve the problems of accelerating the separation of electroplating solution on the surface of printed circuit boards, difficult to handle electroplating impurities, and poor electroplating solution exchange efficiency. , to achieve the effect of recycling electroplating solution, avoiding waste and improving exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

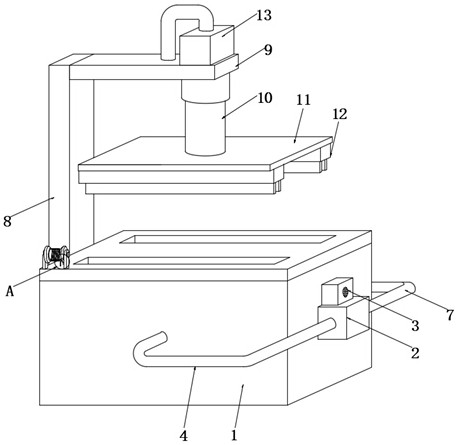

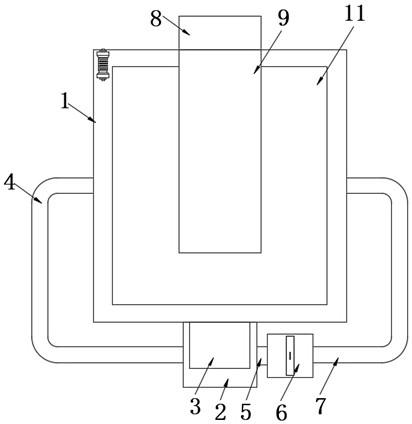

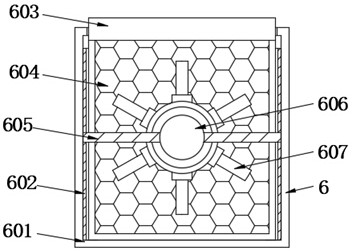

[0037] See Figure 1-8 As shown, the present invention is a printed circuit board processing apparatus applied at a 5G industrial Internet, including a processing tank 1, and a circular pump box 2 is fixedly connected to one side of the processing box 1, and a pump is provided inside the circulating pump box 2. However, the upper surface of the circulating pump 2 is fixedly connected to the drive motor box 3, and a motor is provided inside the drive motor box 3, and the driving motor box 3 operates the pump inside the circulating pump box 2 through the conveyor belt, circulating the pump box 2 The front surface is inserted with a circulation tube one 4, and the circulation tube one 4 is fixed to the front surface of the processing box 1, and the circulating pump box 2 is detached away from the interior of the circulation tube 4, and the dual-channel tube 5, Double Tube 5 Keep away from one end of the circulation pump box 2 with cleaning assembly 6, the cleaning assembly 6 is insert...

Embodiment 2

[0040] Such as figure 1 As shown, the positioning rod 8 is fixed to the side of the processing box 1 away from the circulating pump box 2, and the positioning rod 8 is fixedly connected to a horizontal plate 9, the positioning rod 8 and the horizontal plate 9 are supported by the device. The effect, while the lower surface of the horizontal plate 9 is fixedly connected to the telescopic rod 10, the horizontal plate 9 is fixed to one side of the telescoping rod 10 fixedly connected to the air pressure cylinder 13, and the effect of controlling the stretch rod 10 telescopic is achieved by controlling the operation of the air pressure cylinder 13. When entering the plating operation, the inside of the air pressure cylinder 13 is inflated, and the air pressure cylinder 13 controls the telescoping rod 10 to extend extension, so that the stretcher rod 10 is driven downward, and the fixed panel 11 The surface is configured with a clamping plate 12, followed by a printed circuit board on ...

Embodiment 3

[0043] The inner portion of the processing box 1 is inserted with the drive shaft 15, and one end of the transmission shaft 15 is located inside the circulation pump box 2, and the outer sleeve of the transmission shaft 15 includes a recovery mechanism 16, and the recovery mechanism 16 includes a pulley 1 161, while a belt wheel The front surface activity of the 161 is connected to the hollow tube 163, and the outer sleeve of the drive shaft 15 has a blow fan 162, and the blowing fan 162 is located inside the hollow tube 163, and the motor inside the circulating pump 2 is rotated. Then, the transmission shaft 15 is rotated, so that the transmission shaft 15 is rotated in the interior of the hollow tube 163, so that the wind is blown out inside the hollow tube 163, so that the wind is blown from the two-way outlet winding 164. In the outer surface of the hollow tube 163, the finite-position rod 165 is fixed, and the transmission belt 166 is attached to the outer sleeve of the pulle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com