Graphite boat for liquid phase epitaxy and use method of graphite boat

A liquid phase epitaxy and graphite boat technology, which is applied in the field of liquid phase epitaxy growth of single crystal thin films, can solve the problems of easily scratched surface of thin films and residual mother liquid, and achieve the effect of ensuring film quality, ensuring uniformity and making up for processing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to further explain the technical means and functions adopted by the present invention to achieve the intended purpose, the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

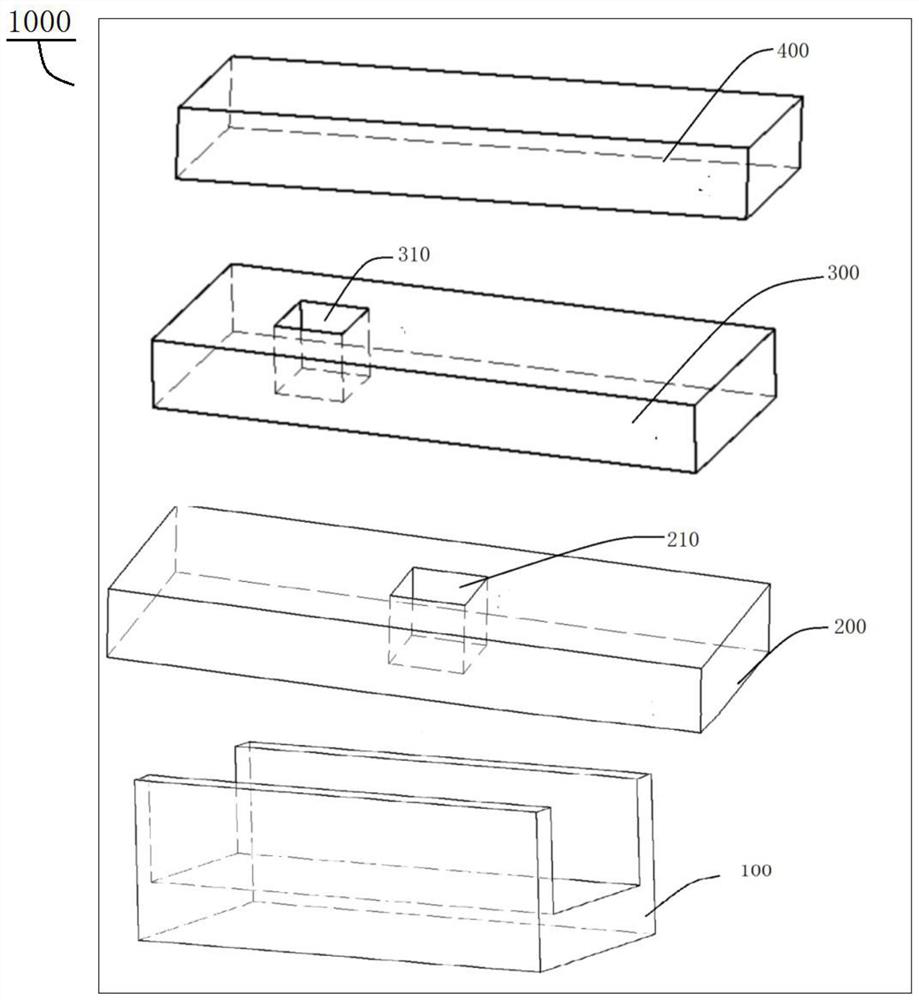

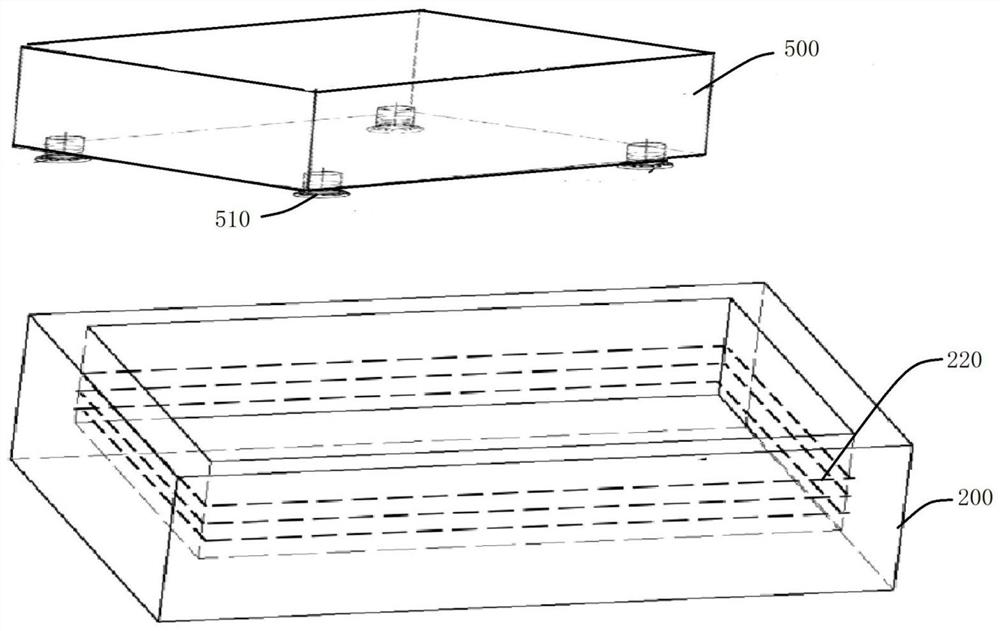

[0041] A graphite boat 1000 for liquid phase epitaxy according to an embodiment of the present invention includes a bottom support 100 and a substrate tank 200 , a mother liquid tank 300 and an upper cover 400 sequentially placed in the bottom support 100 . Wherein, the substrate tank 200 is provided with a first through hole 210 for placing the graphite spacer 500 and the substrate, and the height of the graphite spacer 500 in the first through hole 210 can be adjusted. The first through hole 210 of the substrate tank is provided with a plurality of horizontal scale marks 220 for indicating the height and levelness of the graphite pad 500 .

[0042] The structure of graphite boat 1000 is as follows figure 1 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com