Ecological permeable concrete pavement and preparation method thereof

A technology of permeable concrete and concrete, which is applied to the coagulation pavement, roads, roads and other directions of on-site paving, can solve the problems of low mixing efficiency of mixing devices and achieve the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] An ecological permeable concrete pavement, including a surface layer, a structural layer, a base layer and a base layer arranged from top to bottom, the structural layer is fly ash ceramsite concrete; the base layer is recycled aggregate; the fly ash ceramsite concrete includes the following weight Raw material composition: 450 parts of cement, 700 parts of fly ash ceramsite, 260 parts of recycled aggregate, 6 parts of water reducing agent, and the balance is water.

[0038]A preparation method of ecological permeable concrete pavement, the fly ash ceramsite concrete is made by the following method:

[0039] S1. Fully soak the fly ash ceramsite, and then air dry for 20 hours;

[0040] S2. Put fly ash ceramsite and recycled aggregate into the mixing device, mix for 2 minutes, add cement, water reducing agent and appropriate amount of water and mix for 2 minutes, and finally add all the remaining water and mix for 4 minutes;

[0041] S3, using a rolling tool for rolling ...

Embodiment 2

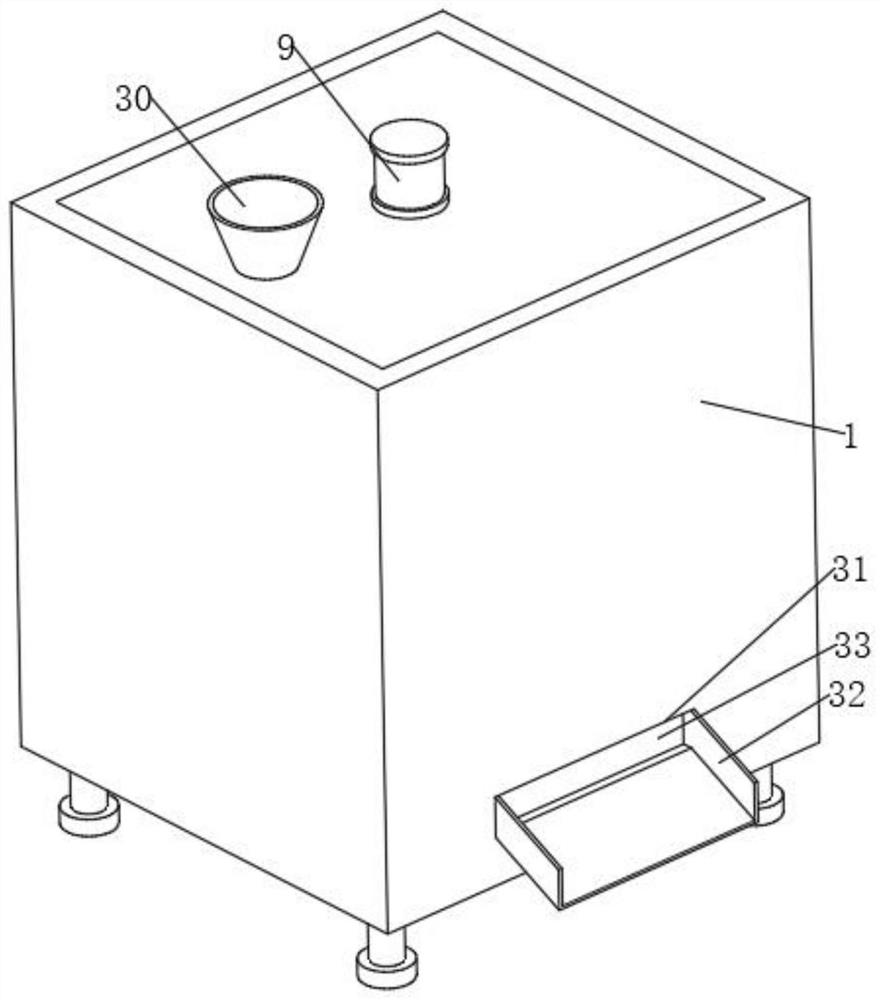

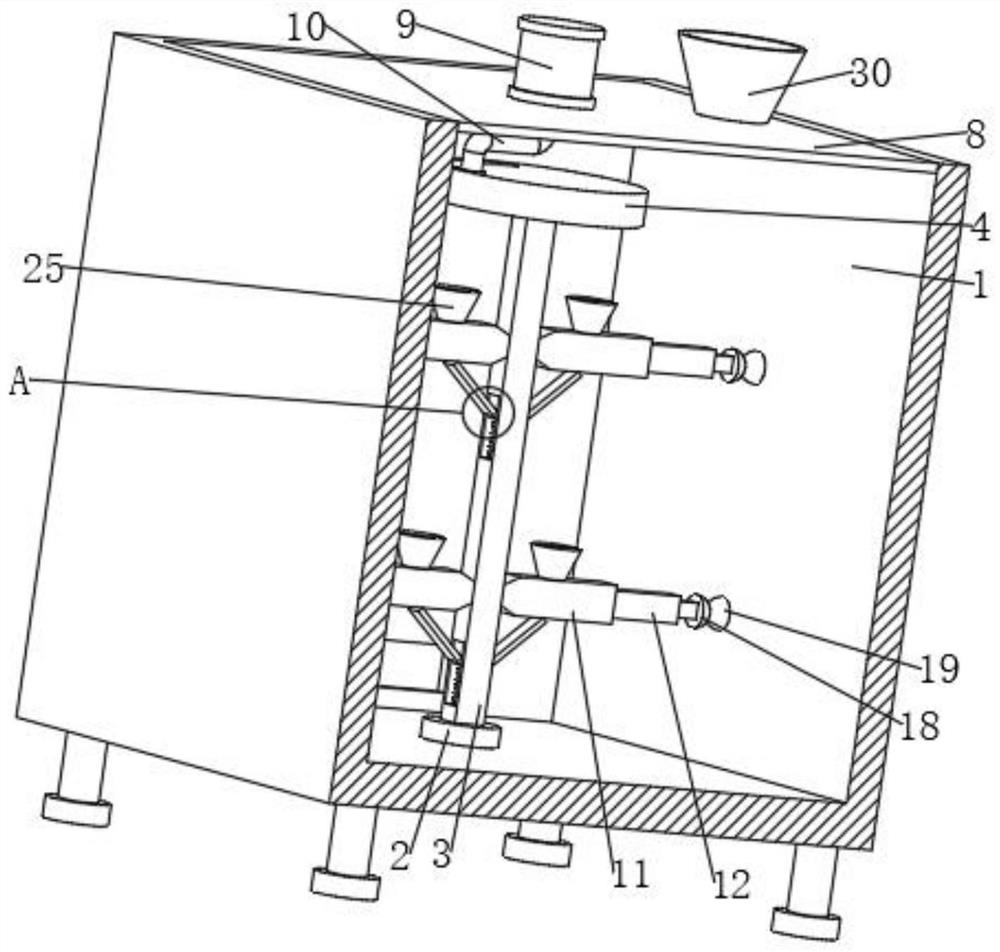

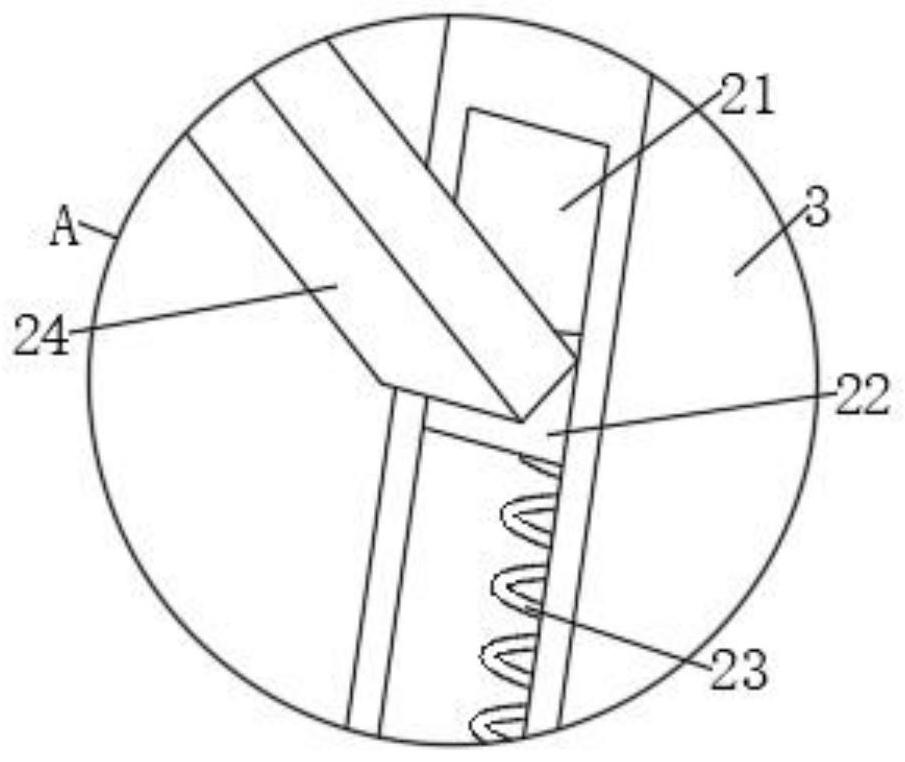

[0044] refer to Figure 1-10 , a method for preparing an ecological permeable concrete pavement, the mixing device includes a box body 1, the bottom inner wall of the box body 1 is connected to a chassis 2 through bearing rotation, the top of the chassis 2 is fixed with a mounting rod 3 by bolts, and the top of the installation rod 3 is fixed with a bolt The top plate 4, the top plate 4 is connected with a driving mechanism, a plurality of evenly distributed sleeve rods 11 are hinged on both sides of the installation rod 3, and a filling cavity 20 is opened on the outside of the sleeve rods 11, and an inner rod 12 is arranged in the filling cavity 20. The outside of the rod 12 is fixed with an impact block 18 by bolts, and the inner wall on both sides of the box body 1 is fixed with an impact block 19 by bolts. Both the impact block 18 and the impact block 19 are arranged in a hemispherical shape. Plate 13, the rear end of positioning plate 13 is provided with the first chute ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap