Inspection well lid supporting pad and manufacturing method thereof

A technology of support pad and inspection well, applied in the field of manhole cover support pad and its manufacture, can solve the problems of destroying the service life and safety of the manhole cover, wear and tear, noise pollution, etc. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

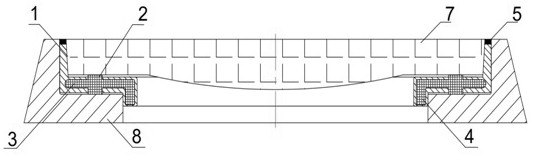

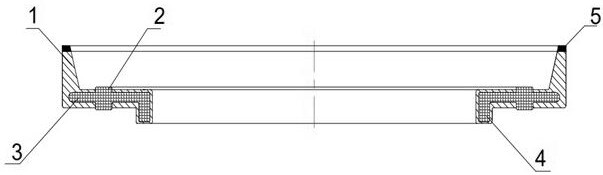

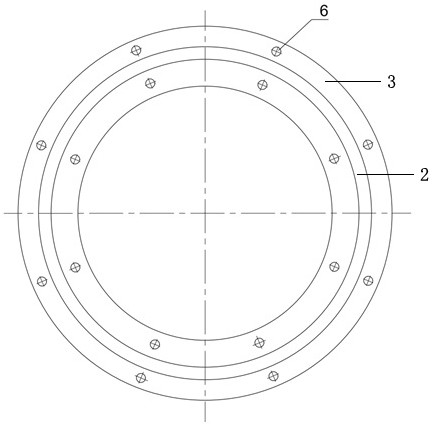

[0030] Embodiment 1: as figure 2 As shown, an inspection well cover support pad is characterized in that it includes a radial support pad 1 , a support frame boss 2 , a support frame 3 , a support frame positioning structure 4 , and a light-resistant layer 5 .

[0031] The support frame 3 is provided with a support frame boss 2 , the support frame boss 2 is perpendicular to the support frame 3 , and one end of the support frame 3 is connected to the support frame positioning structure 4 . The support frame boss 2, support frame 3 and support frame positioning structure 4 are all connected to the radial support pad 1 by molding, and the top of the radial support pad 1 is provided with a light resistant layer 5.

[0032] The inclination of the radial support pad 1 must be 3-10° smaller than the side inclination of the manhole cover 7 .

[0033] The radial support pad 1 is made of silica gel or silicone rubber material with high strength, good resilience, and good weather resis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com