Brake motor protector with multiple safety protection functions and implementation method

A technology of safety protection and braking motor, applied in the direction of brake type, mechanical equipment, etc., can solve problems such as hidden safety hazards, abnormal wear of friction plates, motor burning, etc., and achieve the effect of precise maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

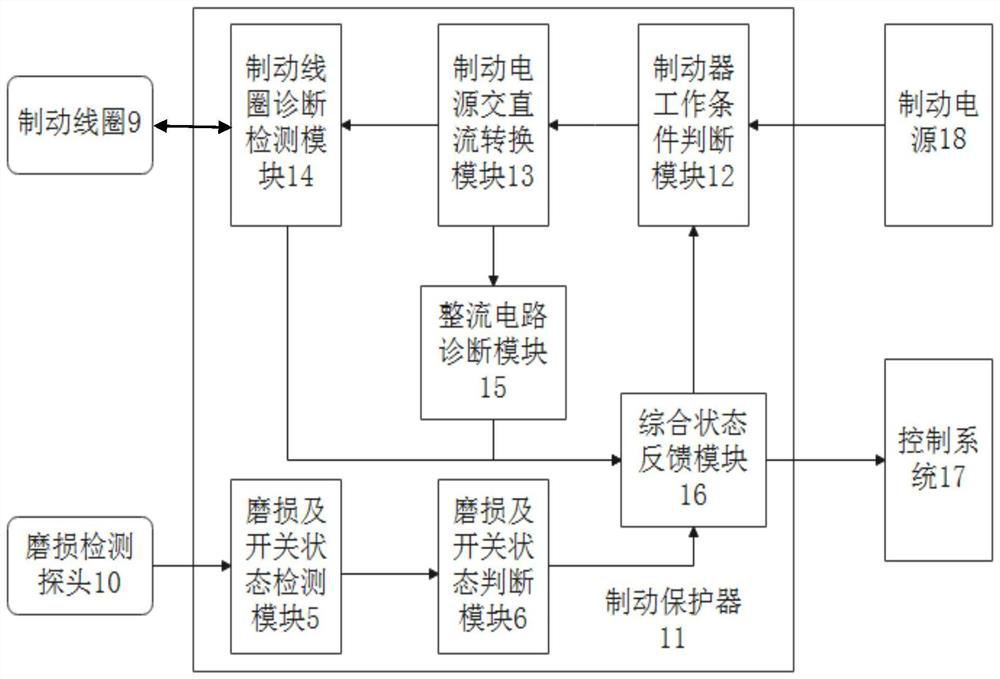

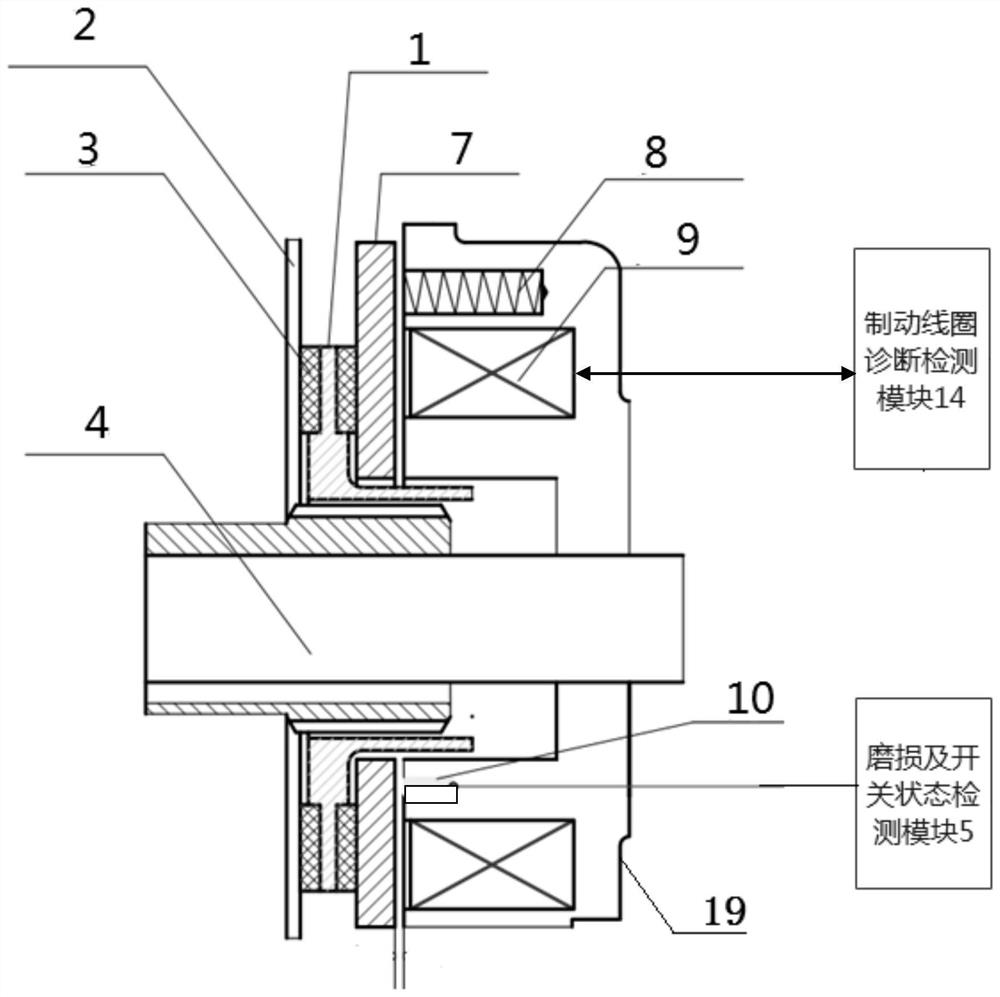

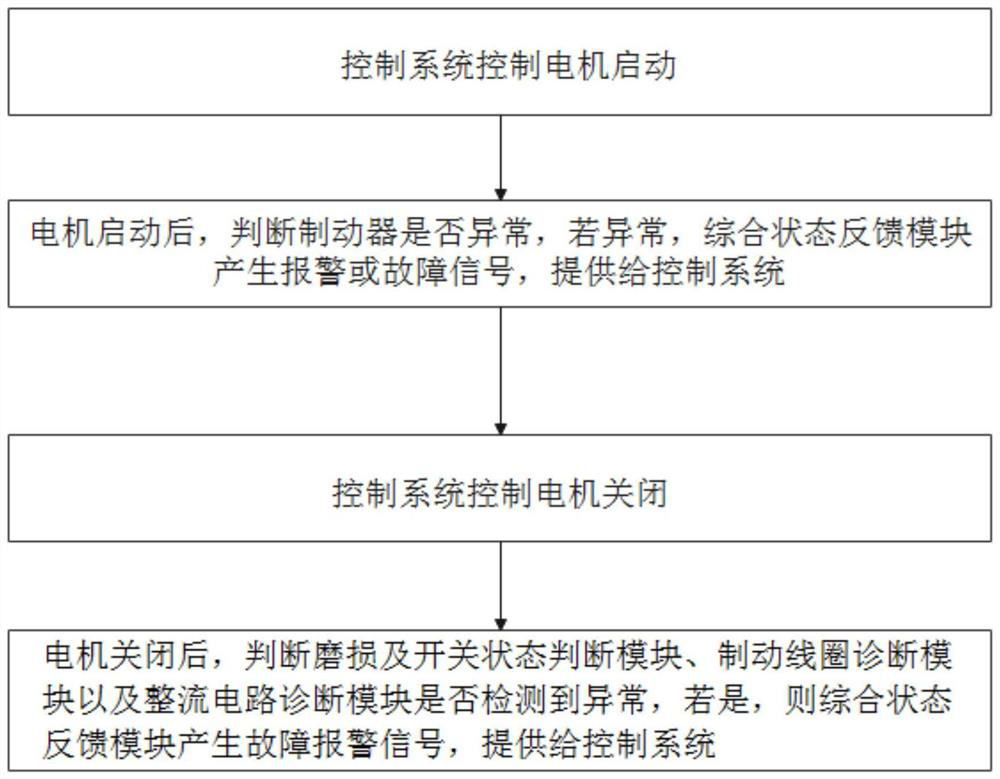

[0071] This embodiment is a brake motor protector with multiple safety protection functions, such as figure 1As shown, it includes a brake, a brake protector 11, a control system and a brake power supply 18. There are a brake coil 9 and a wear detection probe 10 on the brake, and the brake protector includes a wear and switch state detection module 5, wear and switch status judging module 6, brake working condition judging module 12, brake power AC / DC conversion module 13, brake coil diagnosis and detection module 14, rectifier circuit diagnosis module 15 and comprehensive status feedback module 16, the wear and switch status The detection module 5 is connected to the wear detection probe 10 and the wear and switch state judgment module 6 respectively, the brake power supply is connected to the brake working condition judgment module 12, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com