Cobaltous hydroxide airflow drying equipment based on heat cyclic utilization

A cobaltous hydroxide, air-flow drying technology, applied in lighting and heating equipment, drying solid materials, dry cargo handling, etc., can solve the problems of high temperature burns by reclaimers, heat loss of sealed boxes, and reduced temperature of sealed boxes, etc. The effect of reducing heat loss, reducing high temperature burns, and reducing electricity consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

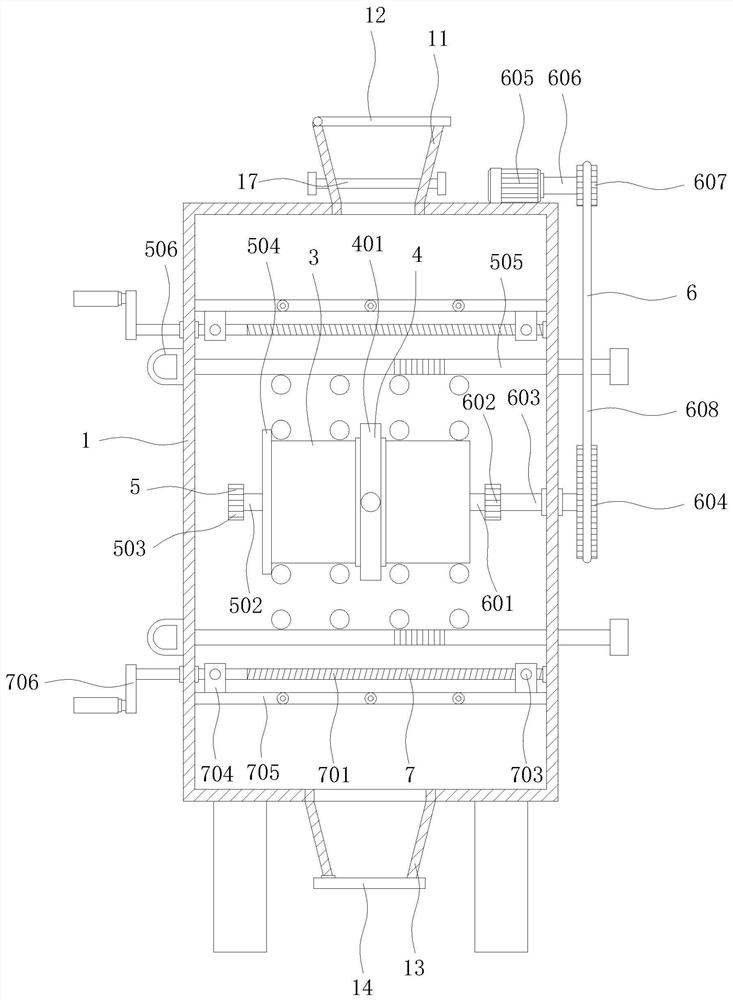

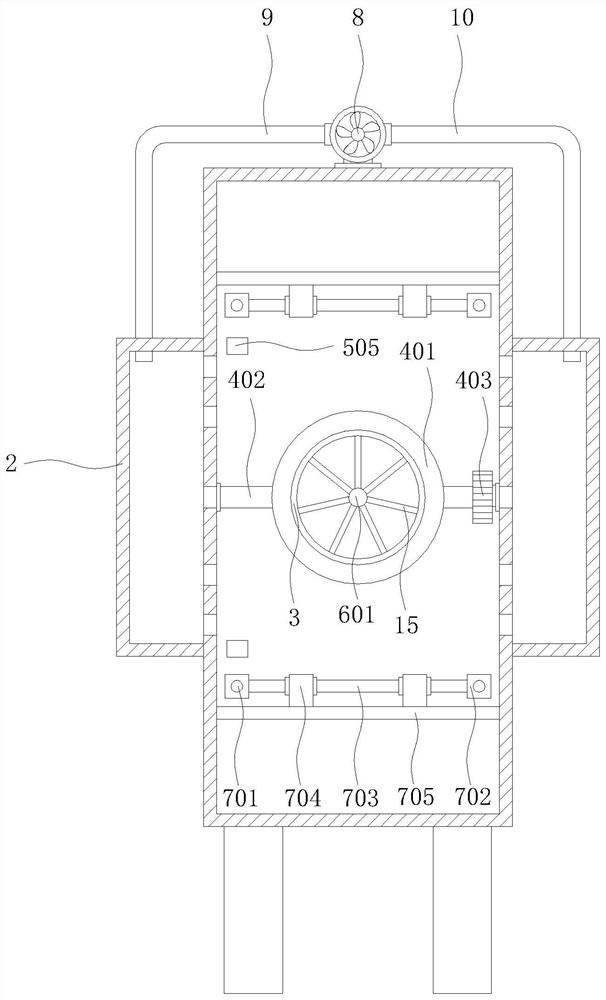

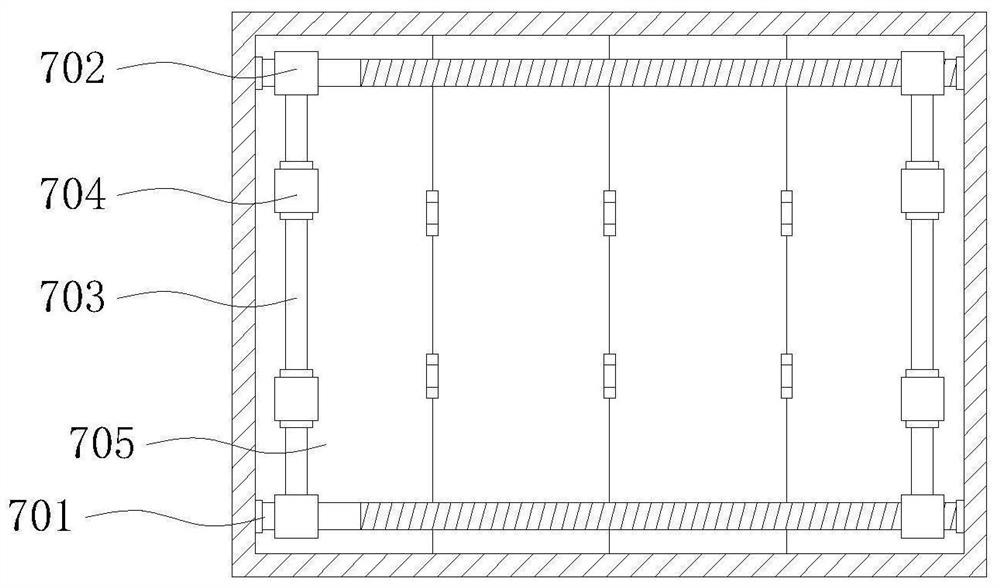

[0028] see Figure 1-7 , the present invention provides a technical solution: a cobaltous hydroxide airflow drying device based on heat recycling, comprising a chassis 1, the front and rear sides of the chassis 1 are provided with vents, and the outer walls on both sides of the chassis 1 are fixedly installed with The air collecting box 2, the inside of the cabinet 1 is provided with a ventilation box 3, one side of the ventilation box 3 is an opening, the outer wall of the ventilation box 3 is provided with a rotating mechanism 4 and an opening and closing mechanism 5, and the outer wall of one side of the ventilation box 3 is provided with Tumbling mechanism 6, an isolation mechanism 7 is provided inside the cabinet 1, a hot air blower 8 is installed on the top of the cabinet 1, the output end of the hot air blower 8 is fixedly installed with an air inlet pipe 9, and the input end of the hot air blower 8 is fixedly installed with an air outlet The pipe 10 , one end of the ai...

Embodiment 2

[0033] see Figure 1-7, on the basis of Embodiment 1, the rotating mechanism 4 includes a fixed plate 401, a connecting rod 402, a rotating tooth 403, an electric push rod 404, a first toothed rod 405 and a fixed block 406, and the outer wall of the ventilation box 3 is rotatably installed with The fixed plate 401, the front and rear sides of the fixed plate 401 are fixedly equipped with connecting rods 402, one end of two groups of connecting rods 402 are respectively installed with the front and rear inner walls of the cabinet 1, and the outer walls of one group of connecting rods 402 are fixedly equipped with rotating teeth 403, The front inner wall of the cabinet 1 is fixedly equipped with an electric push rod 404, the output end of the electric push rod 404 is fixedly installed with a first toothed long rod 405, and the outer wall of the first toothed long rod 405 is slidably installed with a fixed block 406, the fixed block The outer wall of 406 is fixedly installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com