Carbon fiber composite buffering and load-reducing hood and preparation method thereof

A composite material and carbon fiber technology, applied in chemical instruments and methods, offensive equipment, marine torpedoes, etc., can solve the problems of slow water entry, complex connection structure, safe transportation and unsafe storage and use, to ensure coaxiality, Reliable cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

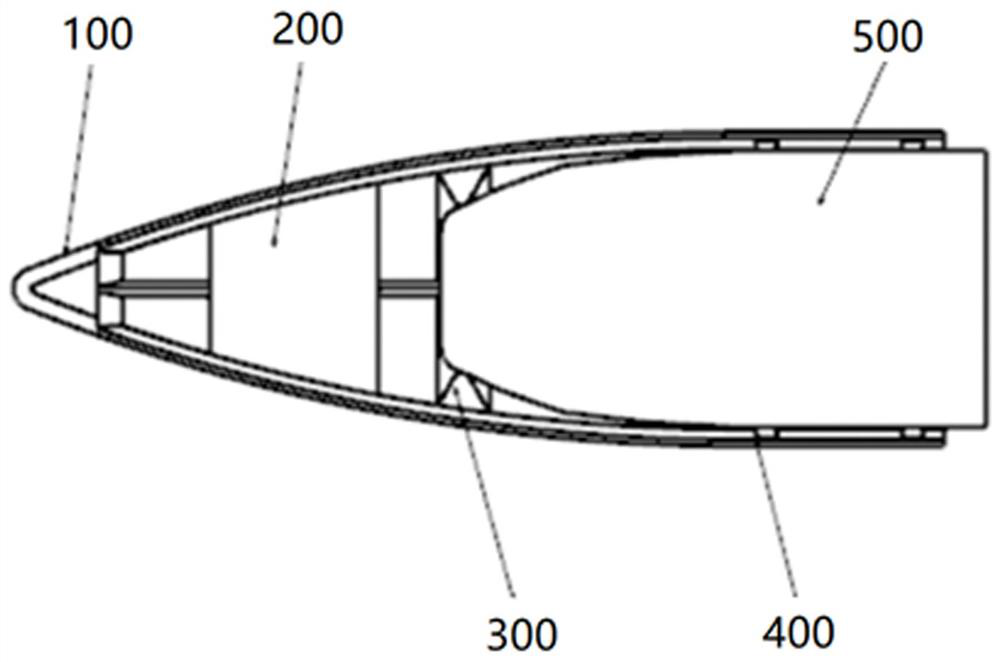

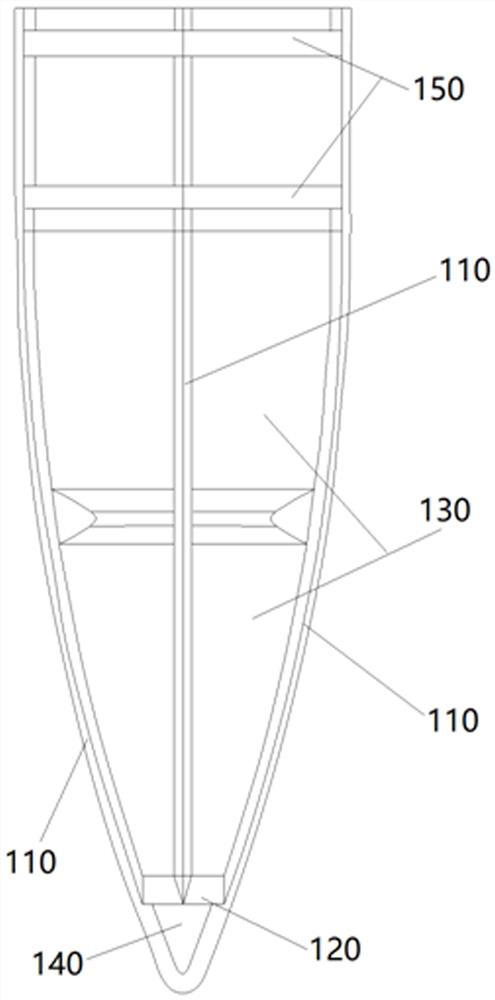

[0032] like figure 1 As shown, the present embodiment provides a torpedo with a carbon fiber composite hood and its components that can reliably crack and reduce the load at a water entry speed of 50-300m / s, so as to solve the problem of the hood in the prior art under different water entry speeds. Reliable separation issues and buffer load shedding issues. The carbon fiber composite material cushioning load reduction head cover provided by the present invention includes: a carbon fiber composite material cover 100, a buffer load reduction assembly 200, a positioning ring 300 and a fixing assembly 400; the buffer assembly 2 is arranged in the carbon fiber composite material cover 100 and is located near the end position, the material is preferably PMI foam with high temperature resistance and high strength; a positioning ring 300 is installed between the buffer assembly 2 and the top of the torpedo; the positioning ring 300 is connected to the carbon fiber composite material c...

Embodiment 2

[0040] On the basis of the above-mentioned embodiments, the present invention further provides a method for preparing a carbon fiber composite cover, comprising the following steps:

[0041] The carbon fiber composite cover 100 is molded using a metal male mold. Lay all the carbon fiber fabric prepregs on different areas of the male mold according to the designed carbon fiber layup sequence. After laying the cloth layers, vacuumize and cure them in an oven at 160-180°C. After the hood is cured, process according to its design requirements. Its profile and internal fixing grooves.

[0042] After the processing of the carbon fiber composite material cover is completed, a layer of PTFE release cloth containing glue is pasted on the bottom of the buffer assembly 2, and then it is loaded into the head cover 1 so that it is tightly attached to the inner wall of the carbon fiber composite material cover, and then placed on the The mid-section of each sub-lobe of the carbon fiber com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com