Tensile test method and device for cable insulation dumbbell test piece

A cable insulation and tensile testing technology, applied in measuring devices, using stable tension/pressure to test material strength, instruments, etc., can solve problems such as loss of mechanical properties, weight tension tilt, temperature changes, etc., to improve the accuracy of determination , Guaranteed accuracy, convenient detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

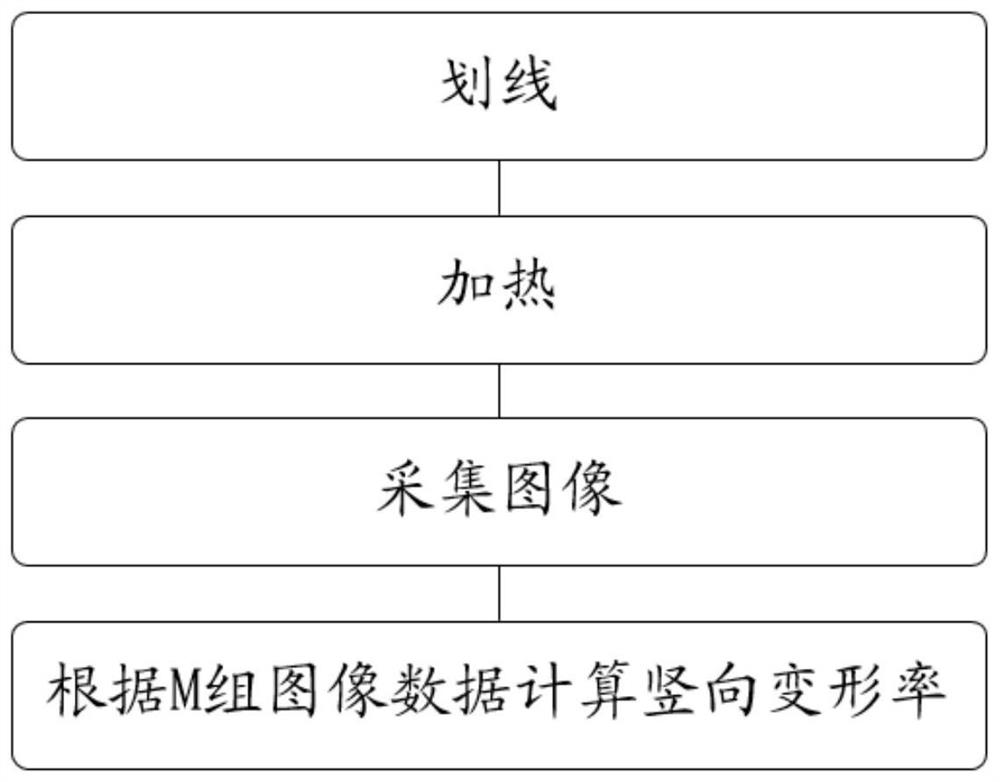

[0073] Such as figure 1 Shown, a kind of tensile test method of cable insulation dumbbell test piece, comprises the following steps: step S100-step S500:

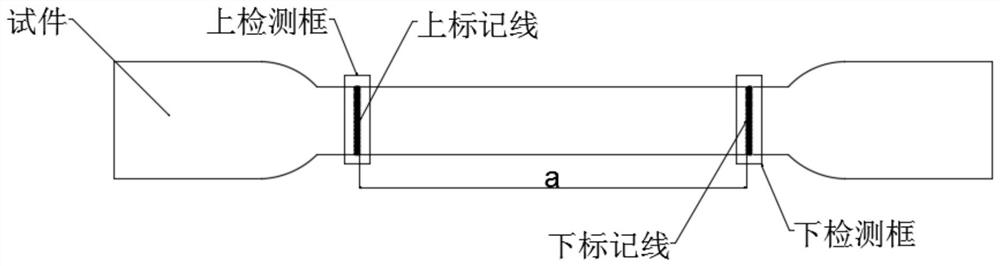

[0074] Step S100, scribing: draw an upper marking line on the upper end of the prepared N test pieces, and draw a lower marking line on the lower end, and set the distance between the upper marking line and the inner side of the lower marking line as a, so The lengths of the upper marking line and the lower marking line are both b;

[0075] In step S100, if figure 2 As shown, make a dumbbell test piece first, and the dumbbell-shaped cable insulation is cut out by a mold, mainly black and white translucent; two marking lines need to be drawn on the dumbbell test piece, and black marks are used for the white test piece For strokes, use white marker strokes for black test pieces, and it is recommended to use green marker strokes to improve contrast.

[0076] Initially measure the inner distance between the two marking line...

Embodiment example

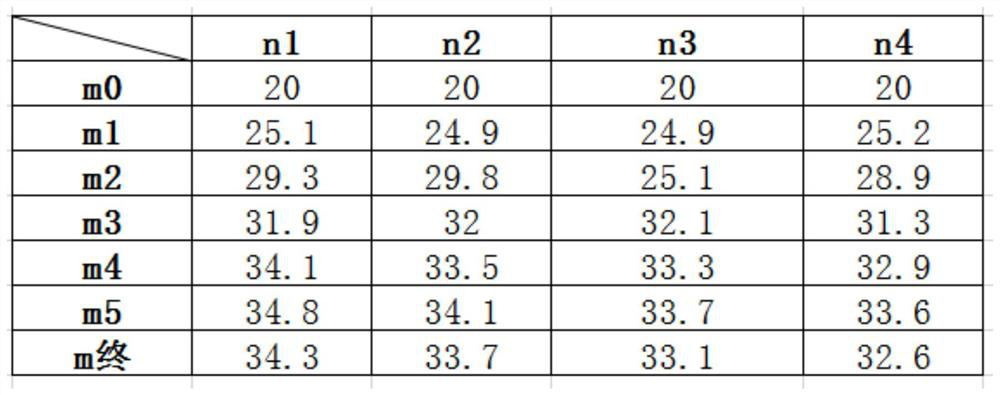

[0118] Implementation case: The working steps of the entire thermal extension test automation device:

[0119] 1. Turn on the power, start the industrial computer, and open the control software; when shooting continuously, the time for an industrial computer to analyze 4 pictures is 120ms, and the real-time length is refreshed 8 times per second;

[0120] 2. Set the temperature of the experimental device to 200 degrees Celsius and start heating; the experimental device can use an oven;

[0121] 3. Manually clamp the dumbbell specimen with measured thickness to the hanger;

[0122] 4. Input the thickness, number, and report number of the 4 dumbbell test pieces, and the number and report number can be numbered according to the time;

[0123] 5. Computer control page input thickness calculation load;

[0124] 6. Pull open the sliding door of the experimental device, and place the hanger on the sliding door of the experimental device;

[0125] 7. Push the sliding door into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com