A feeding device and a cell feeding method

A battery and material box technology, which is applied in the direction of circuits, electrical components, transportation and packaging, etc., can solve the problems of silicon falling of the battery, collision between the battery and the feeding device, damage of the battery, etc. Effects with controllable range and controllable separation height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

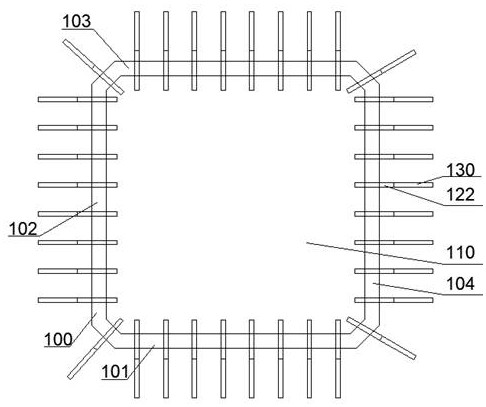

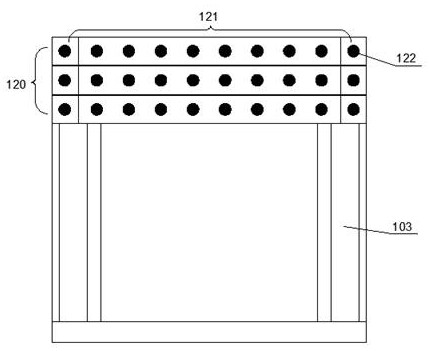

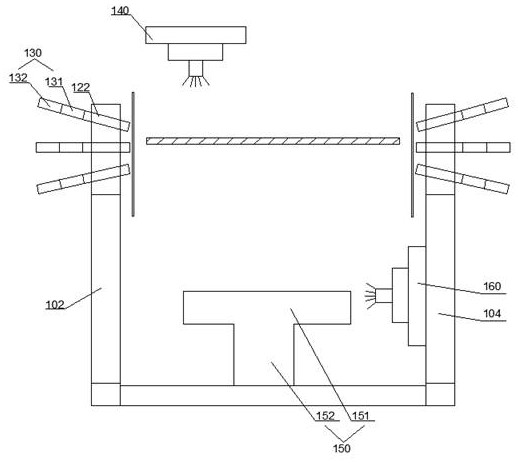

[0030] The embodiment of the present application provides a feeding device and a charging method for battery slices. By setting air hole arrays on the front side plate, left side plate, rear side plate, and right side plate, the gap between the battery slices and the loading box is avoided. Collision.

[0031] Various embodiments of the present application will be described in detail below in conjunction with the accompanying drawings. However, those of ordinary skill in the art can understand that in each embodiment of the application, many technical details are provided for readers to better understand the application. However, even without these technical details and various changes and modifications based on the following embodiments, the technical solutions claimed in this application can also be realized.

[0032] refer to Figure 1 to Figure 3 , figure 1 A top view of a loading box provided in the embodiment of the present application; figure 2 A side view of a fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com