Method for processing round metallic wire rod, apparatus for processing round metallic wire rod, and production method for power distribution component

A processing method and a technology of a processing device, which are applied to metal processing equipment, etc., can solve problems such as difficulty in positioning and position deviation that cannot be completely eliminated, and achieve the effects of easy alignment, improved bending processing accuracy, and improved dimensional measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

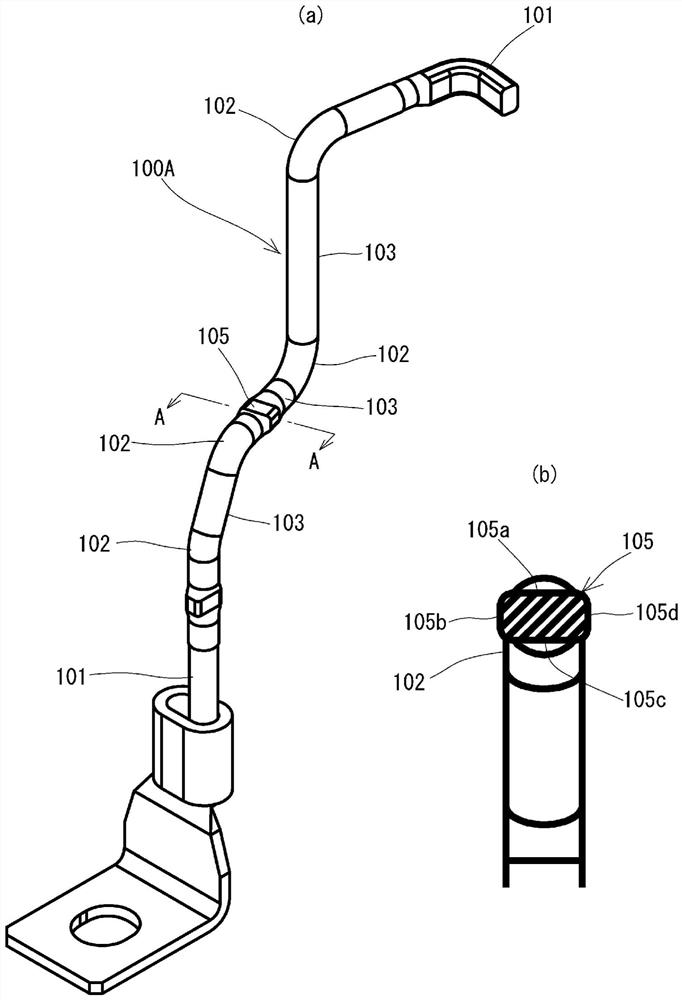

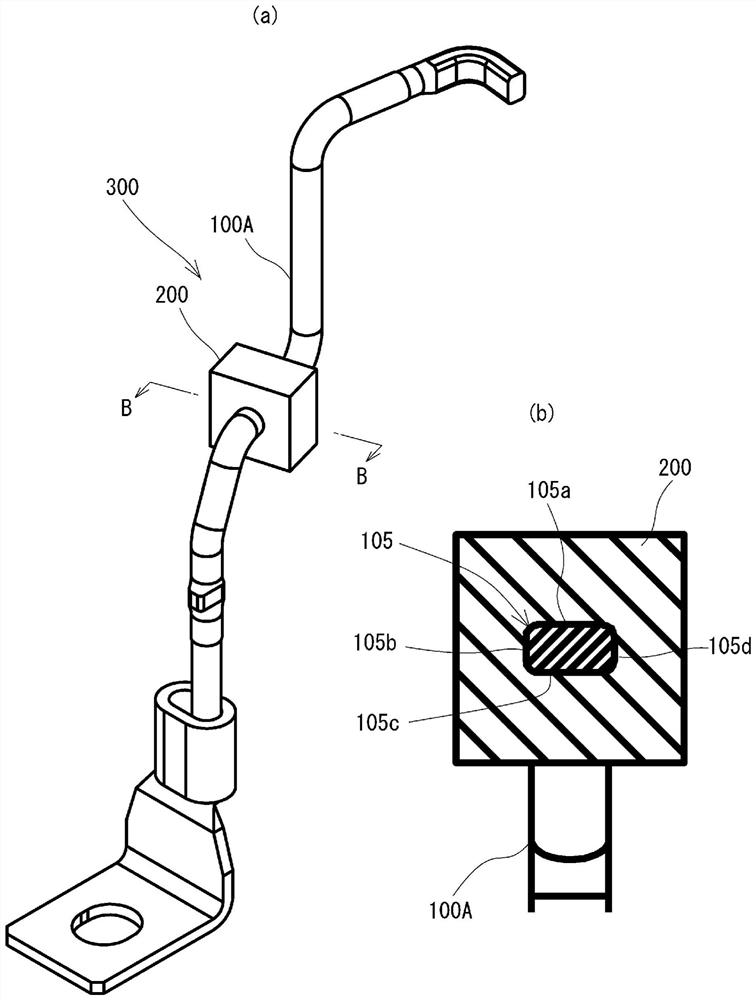

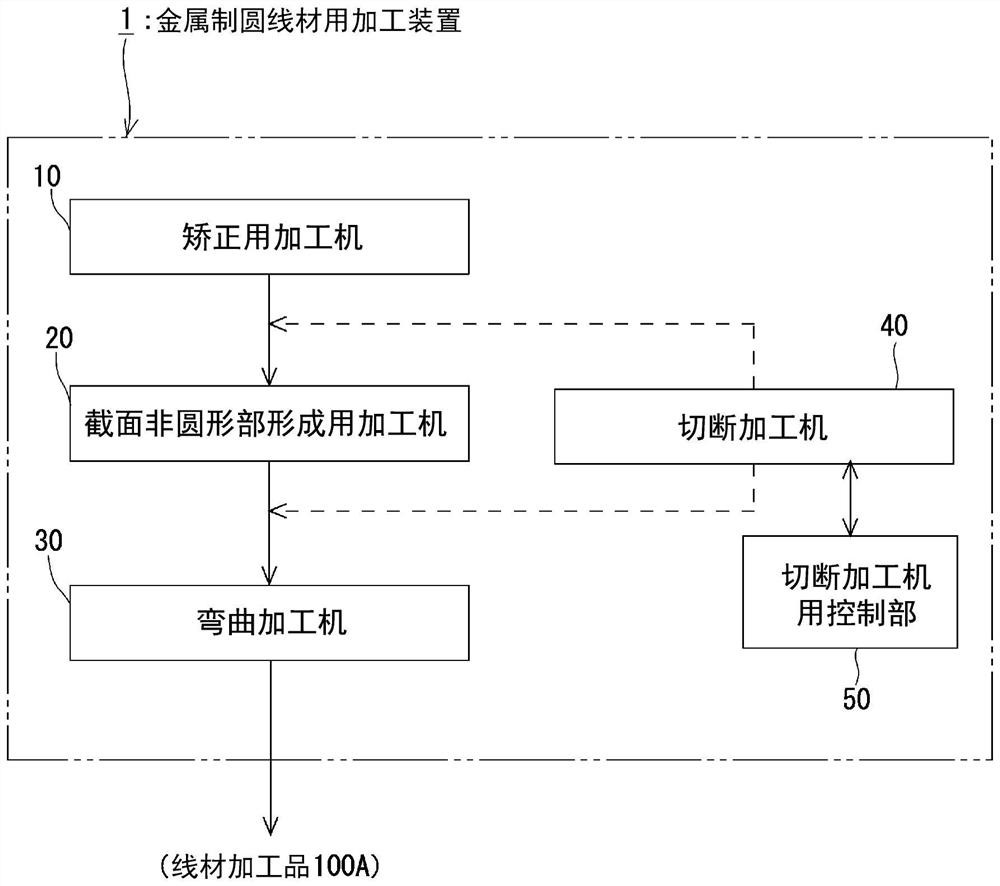

[0041] Hereinafter, embodiments of the present invention will be described with reference to the drawings. figure 1 (a) shows the metal round wire processing apparatus 1 using one embodiment of the present invention (refer to image 3 ) processed metal round wire 100 (hereinafter referred to as "wire processed product") 100A. This processed wire product 100A is used, for example, as a power line of a motor or the like as disclosed in Patent Documents 1 and 2, and is formed to include connection parts 101, 101 connected to terminals and the like at both ends, and a plurality of bent parts 102, 102. , and the three-dimensional shape of the straight parts 103, 103 between the plurality of curved parts 102, 102. In addition, in the present embodiment, at any part of the processed wire product 100A, the diameter direction of the metal round wire 100 (the distance between the metal round wire 100 and the distance between the metal round wire 100) is formed within the range of the str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com