Suction device for a service robot for a yarn manufacturing textile machine, a service robot, and a textile machine

A suction device and yarn manufacturing technology, which is applied in the field of ring spinning machines and yarn manufacturing textile machines, can solve the problems of structure and manufacturing complexity, energy intensity, etc., and achieve the effect of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

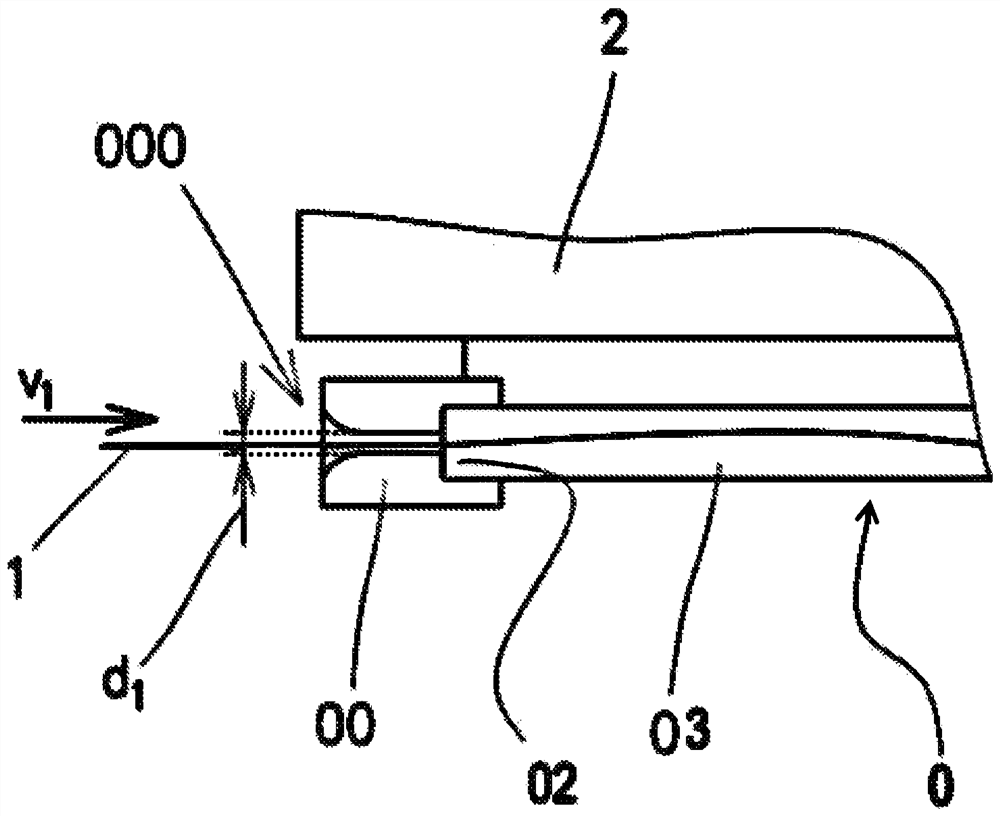

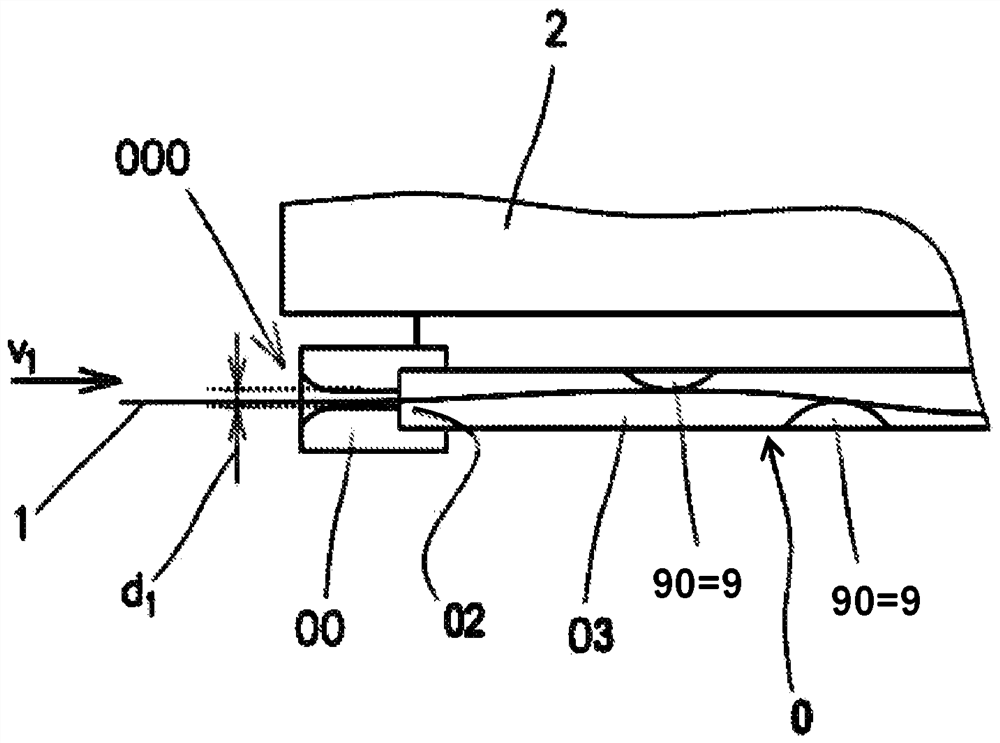

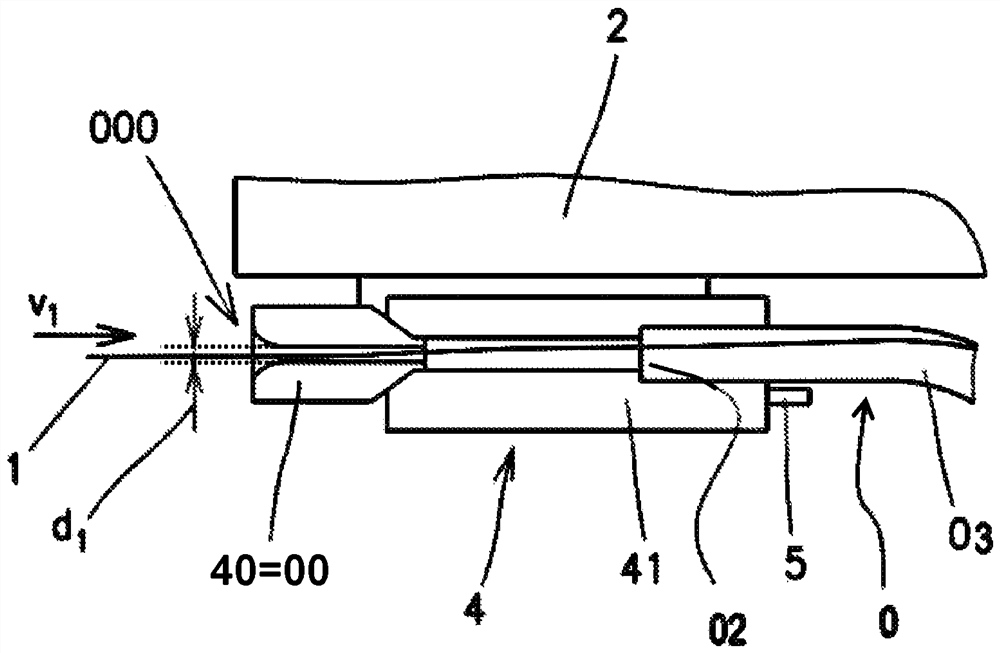

[0036] The invention will be described with reference to an exemplary embodiment of a device for suction and delivery of yarn 1 arranged on a maintenance robot of a yarn manufacturing textile machine, in particular a ring spinning machine. A yarn manufacturing textile machine (ie also called a ring spinning machine) comprises at least one row of identical spinning stations (not shown) arranged next to each other. Each spinning station comprises not shown nodes and devices for producing yarn 1 and for winding the yarn on bobbins not shown.

[0037] The textile machine also comprises at least one maintenance robot reversibly movable along the row of spinning stations and provided with a system of nodes and devices for performing maintenance operations and activities at the spinning stations.

[0038] One of these robotic nodes and devices for carrying out maintenance operations and activities at the spinning station is a manipulating mechanism 2 for spatially manipulating the ya...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com